17/02/2026

Once

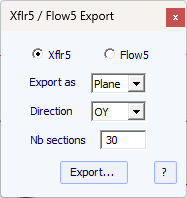

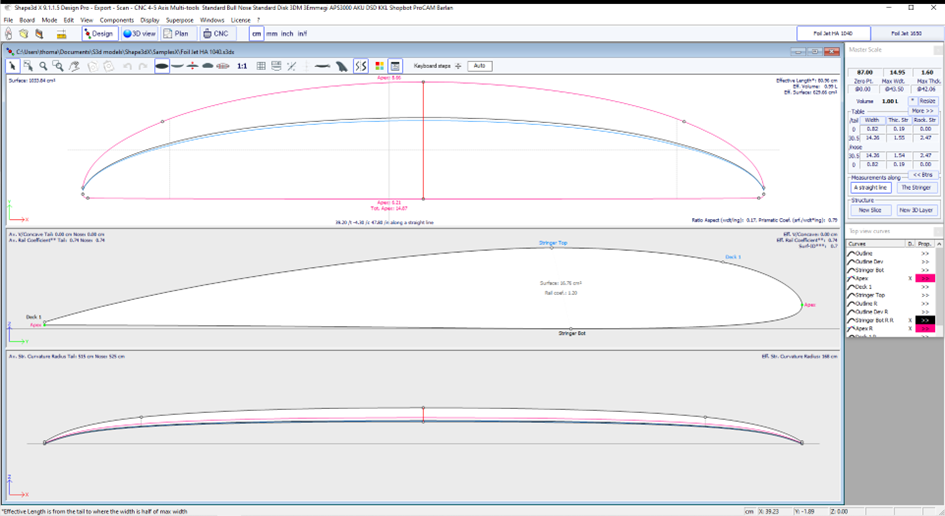

the foil has been designed in Shape3d, you can export it to Xfrl5 or Flow5 from

the menu File -> Xflr5/Flow5 export, Component -> Slices -> NACA

profile generator menu:

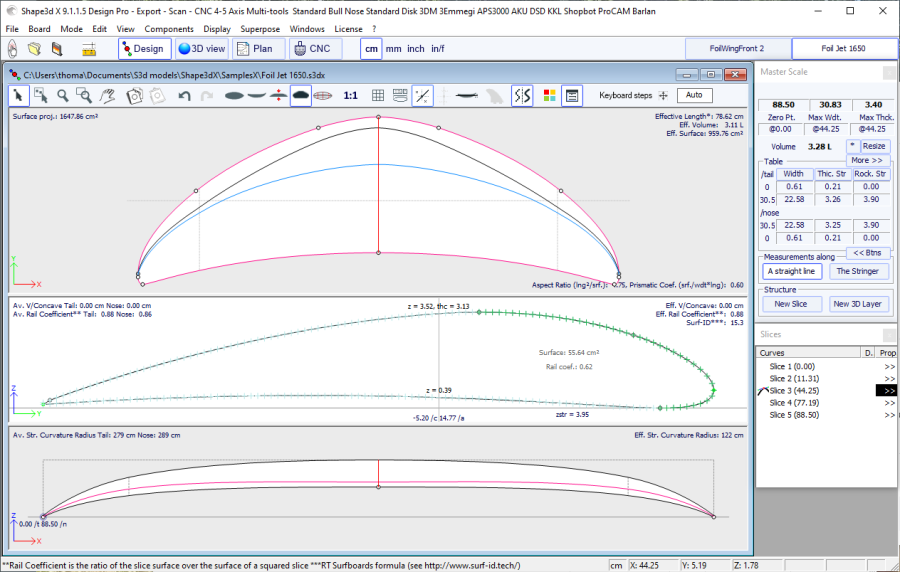

Note that

the foil must be designed as in the screenshot delow: with the leading edge to

the right, and the trailing edge to the left.

Xflr5 is

open source software that can be downloaded from https://www.xflr5.tech/xflr5.htm

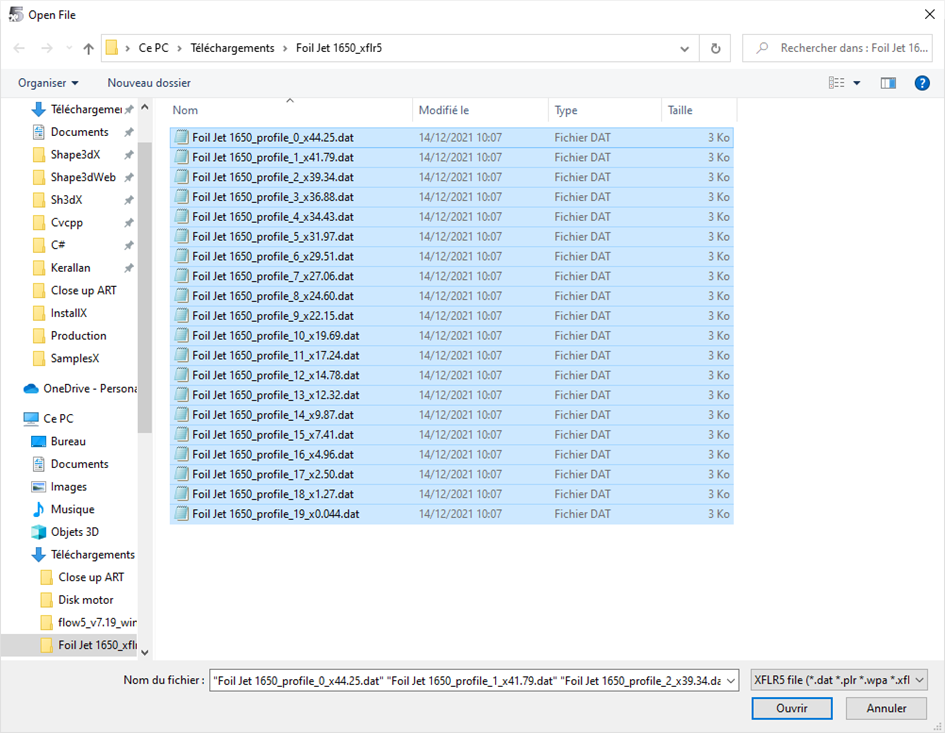

The export consists of the defined number of

.dat profiles (30 here) and an xml file.

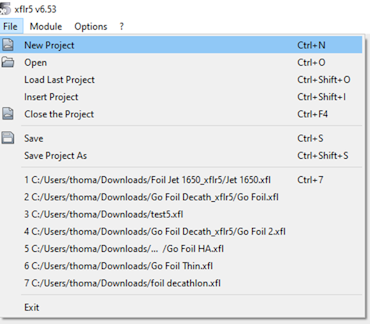

Open

Xflr5 and click on the File -> New Project menu:

Then

File -> Open, and select all the .dat:

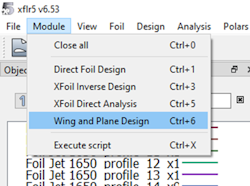

Then go to

the menu Module -> Wing and Plane Design:

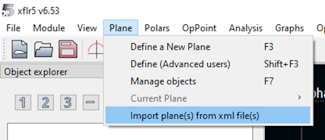

Then Plane

-> Import plane(s) from xml file(s):

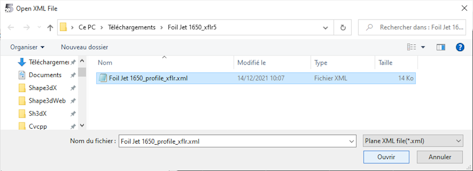

And select

the xml file exported by Shape3d:

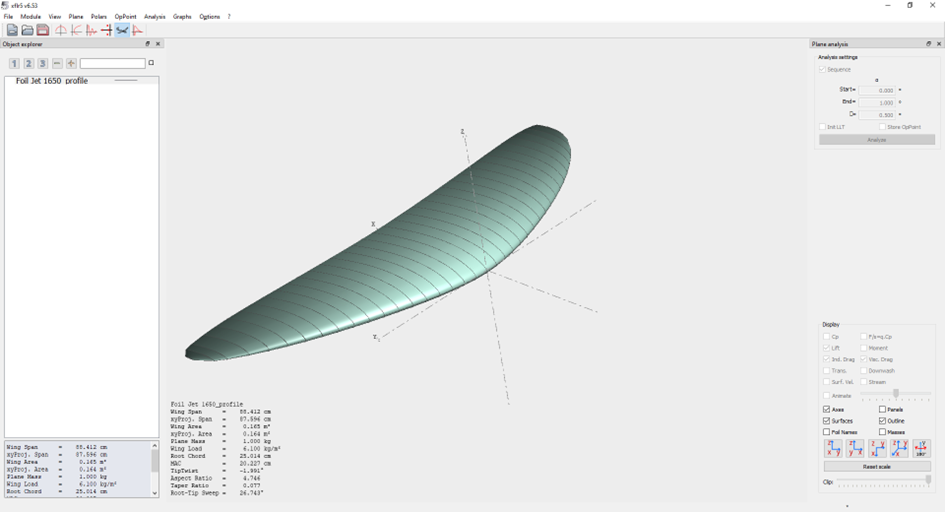

In 3D View

mode, we can check that the foil has been imported correctly:

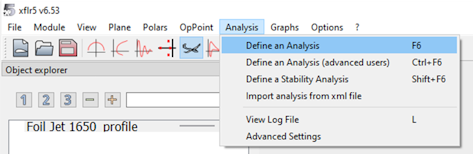

We can then

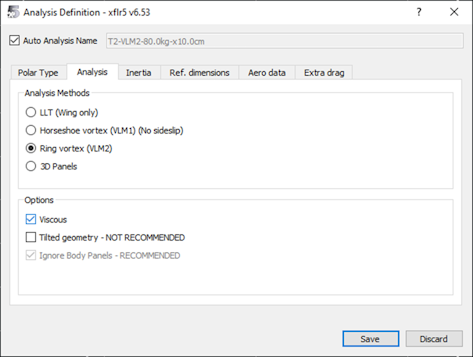

directly launch a lift analysis from the Analysis -> Define an Analysis

menu:

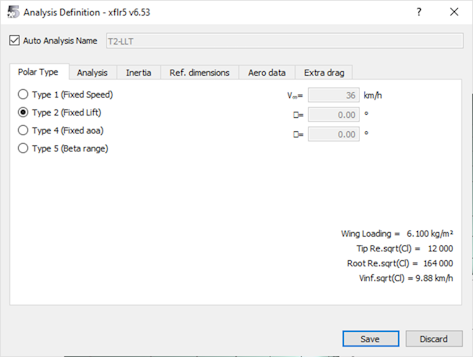

You can do

an analysis at a given speed (Type 1), or at a given lift (Type 2). The Type 2

analysis is very interesting to see how a foil will behave with a given user:

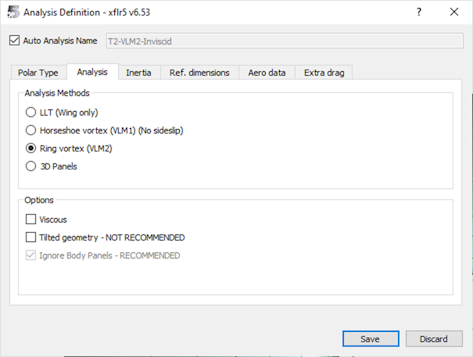

You must

then choose the method in the Analysis tab. Ring vortex works well. We're not

going to check Viscous just yet, which will allow us to get lift faster.

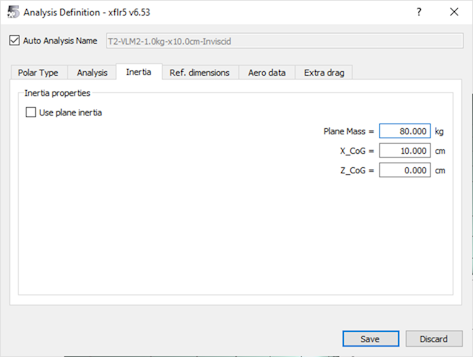

In the

Inertia tab we enter the weight of the rider + gear, 80kg for example:

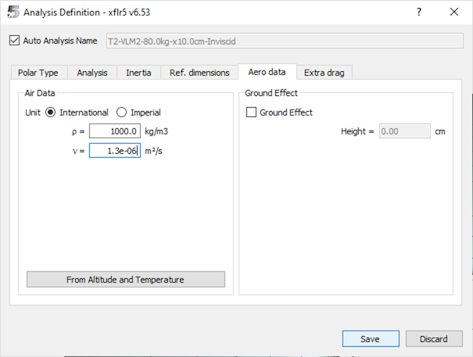

Then in the

Aero data if tab, enter the water density 1000kg / m3 and its viscosity 1.3e-6

m² / s:

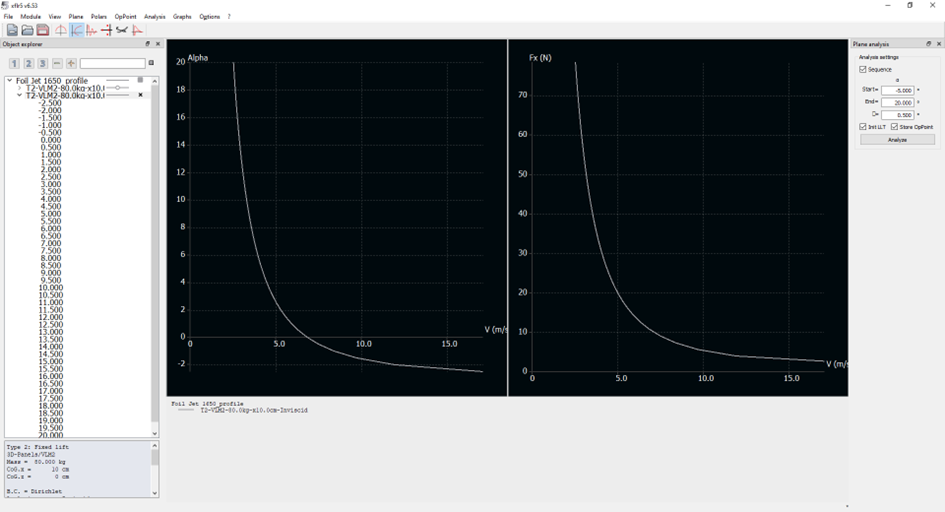

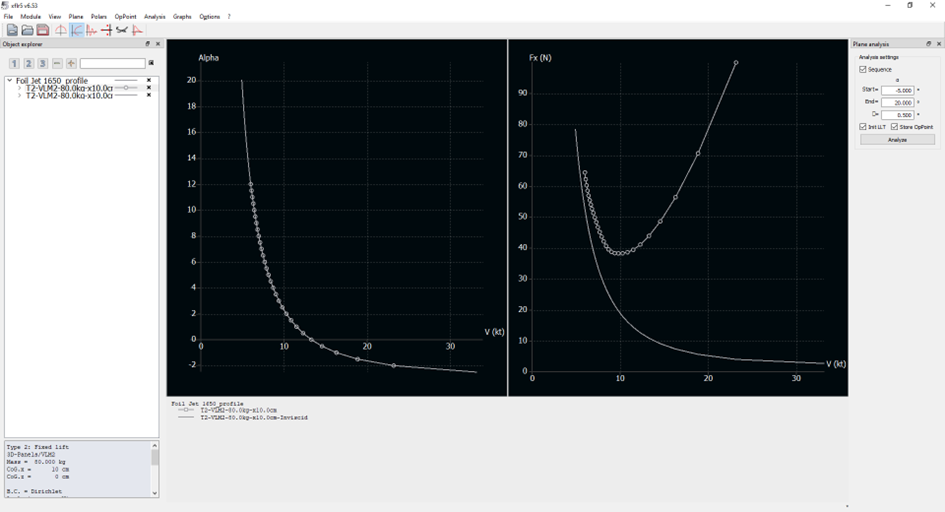

We click on

the Save button, then in Polar View mode we click on the Analyze button to

start the analysis:

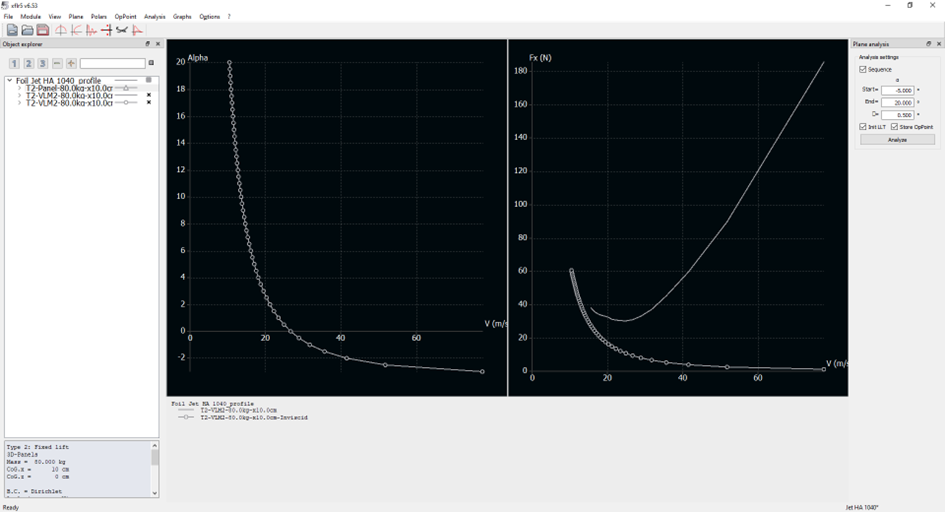

This

analysis calculates for each inclination of the foil (here between -5 ° and 20

°) the speed it takes for the foil to carry 80 kg (a lift of 784 N therefore).

You can also display the drag Fx for each speed (with the inclination that

corresponds to it).

Here we see

that for this low aspect 1650cm² foil (rough copy of the Naish Jet 1650), at 5

m/s (~ 10 kt) you need an inclination of 2 °. Below 6 kt it takes more than 12

°... We can deduce that we can start pumping around 6 kt, but that normal

navigation is only done from 10 kt roughly.

The drag Fx

is here only the residual drag due to the vortices, and we see that it is

greater the lower the speed and the large inclination. It only decreases as

speed increases, which is unrealistic as there is no viscous drag.

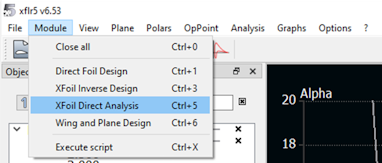

To add the

slimy drag it is a bit longer. You have to go to the menu Module -> XFoil

Direct Analysis:

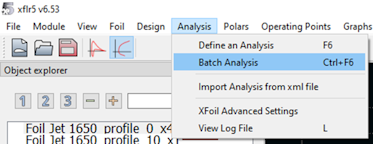

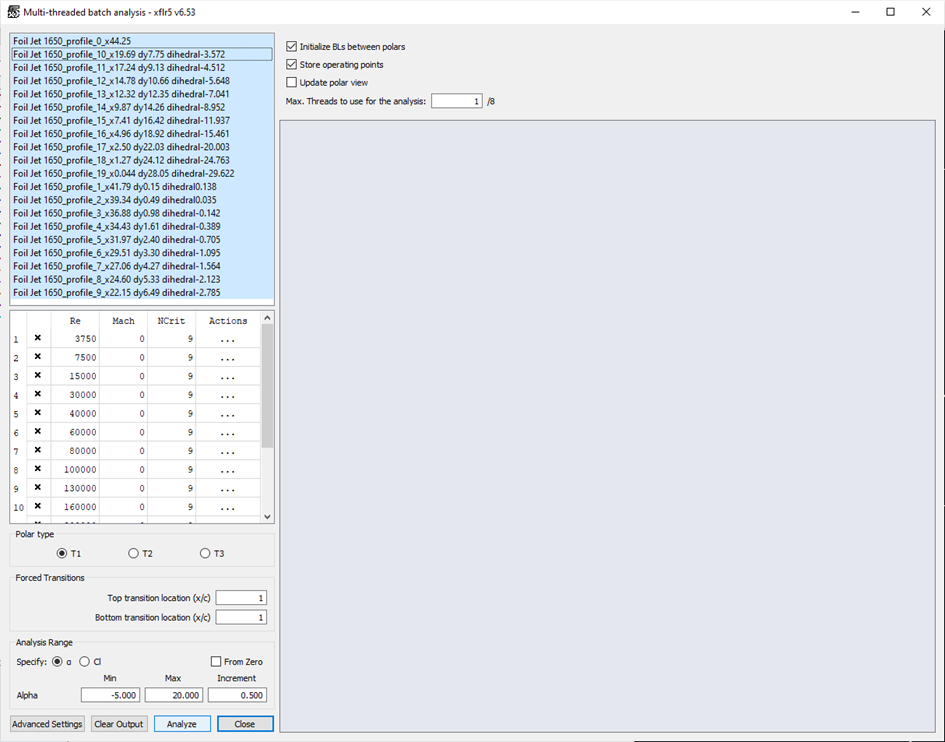

Then in the

Analysis -> Batch Analysis menu:

Then select

all the profiles, and launch the Type 1 analyzes between -5 ° and 20 °:

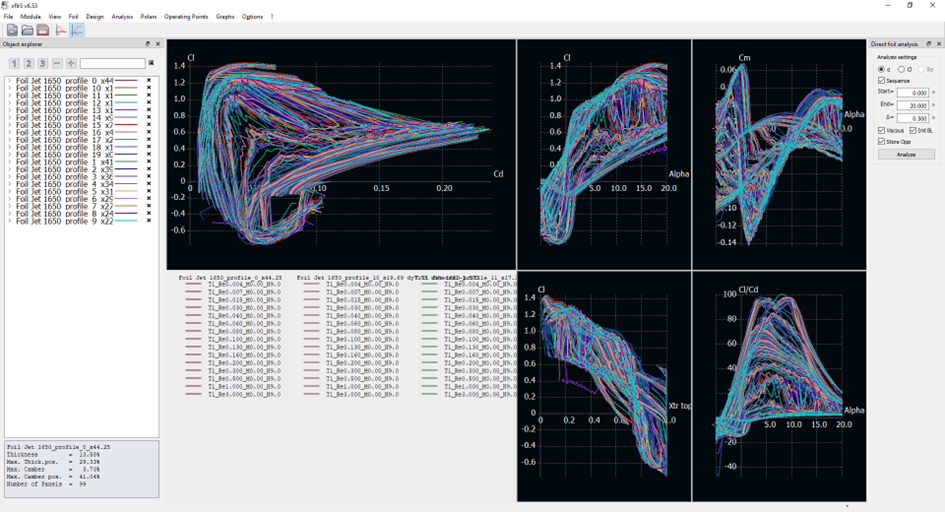

It takes

several minutes, and at the end of it, the polars for all angles and Reynolds

numbers between 4000 and 3e6 are displayed.

We can then

return to the Module -> Wind and Plane Design menu, and define a new

analysis, by checking the Viscous box this time:

We obtain a

lift identical to the previous analysis, but a higher drag which increases at

high speed. There is therefore a minimum drag for a given inclination and

speed:

There is

therefore an optimum range of use between 9 kt and 12 kt.

Note that

you can change the speed unit in the Options -> Preferences menu, but there

is a small bug that causes the display to always revert to m/s with a scale

that is not always good . You must then right click -> Current Graph ->

Define Grapgh Settings, then Reset Graph Scales.

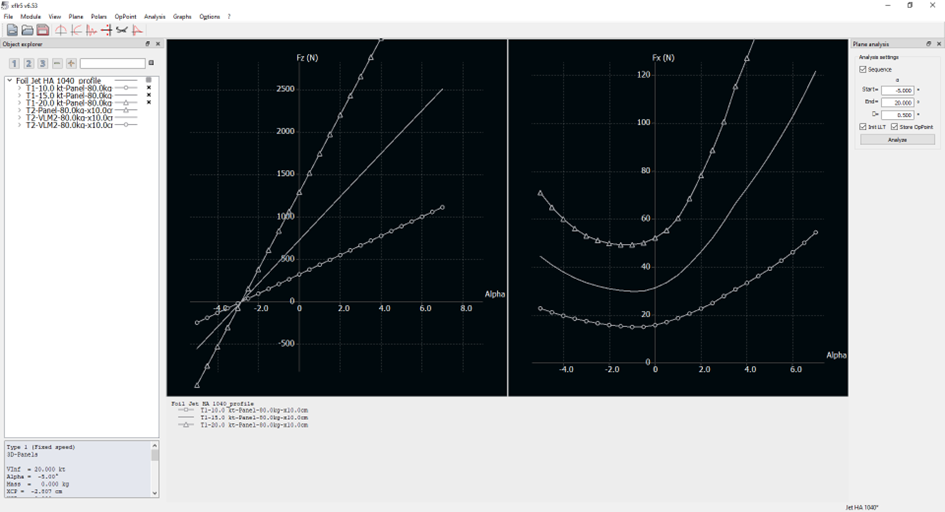

We can

compare these results with a foil of 1040 cm² of higher aspect ratio (rough

copy of the Naish Jet HA 1040):

We can see

here that the bank at 10 kt is not 2 ° but 4 °. We descend to 2 ° around 12 kt.

The minimum drag is around 14 kt, and the optimum range between 12 kt and 16

kt.

These

results are not 100% reliable, but fairly true. We made a quantitative

comparison with the results obtained with OpenFoam (a large simulation

software, the analyzes are very long and require large computers) by Decathlon

and we were very close to the lift level for inclinations of up to 15 °. The

advantage here is that it takes less than 5 min in total to get an analysis.

You can

also do Type 1 analyzes to obtain the optimum incline at a given speed

(10-15-20 kt here):

You can

also add a stabilizer: in Shape3d export it as a Wing, and then add it to the

plane you already created/

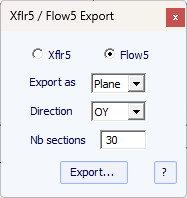

The same procedure

can be done to export your foil to Flow5, which is more advanced than Xflr5,

and which is now free as well:

https://flow5.tech/flow5.html

In Shape3d,

make sure you export your foil wing as a Plane:

Then the

.dat profiles and an Xml file will be exported to the selected folder just as

for the Xflr5 export.

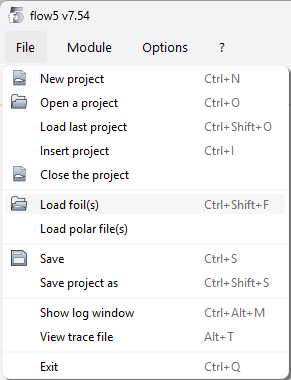

In Flow5,

create a new plane, and go to the menu File / Load foil(s) to load the .dat

profiles.

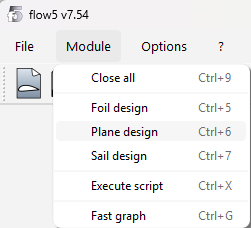

Then go to

the menu Module / Plane design:

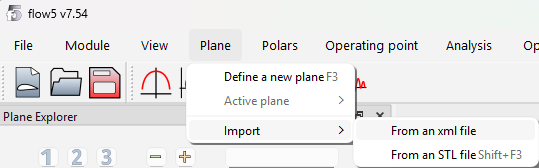

And then

Plane / Import / From an xml file:

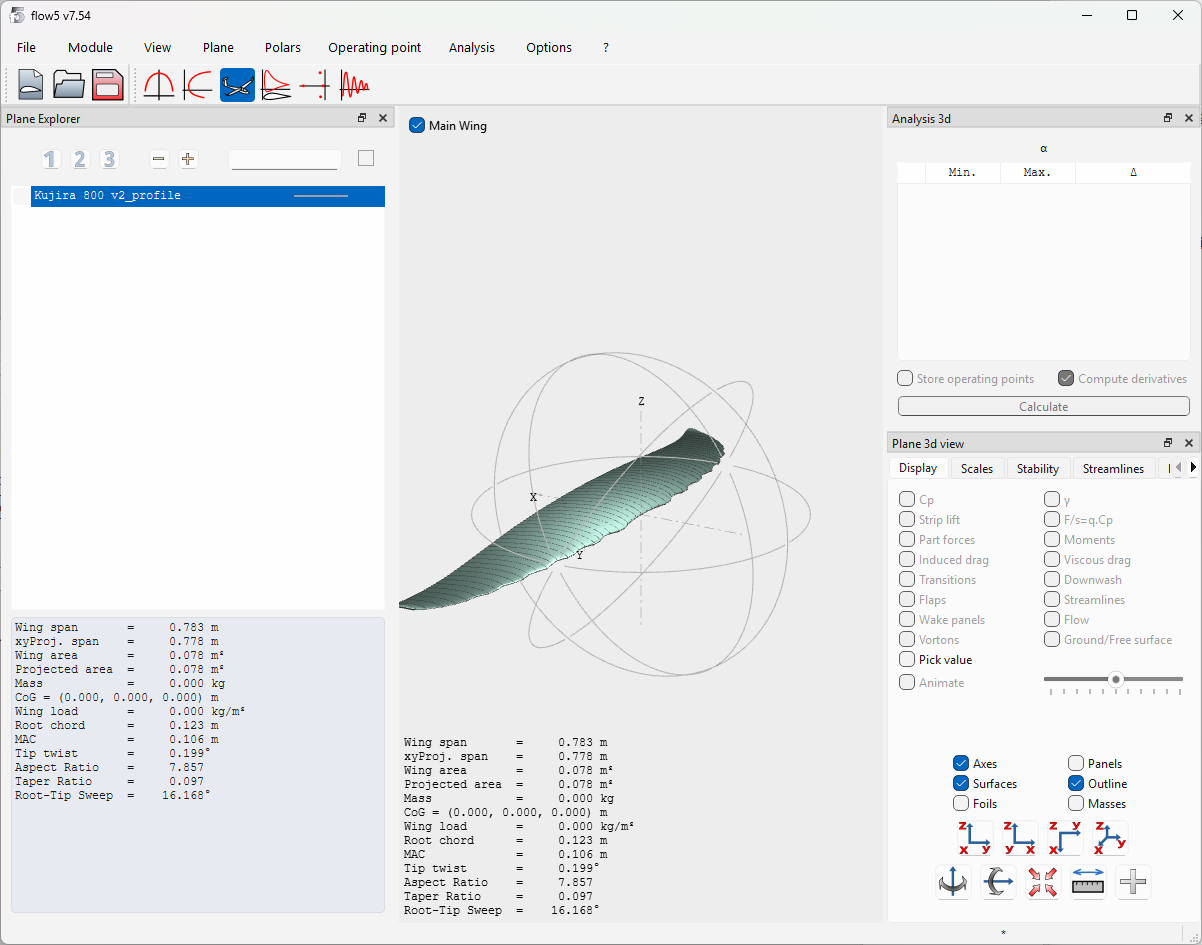

You’ll see

the result of the importation straight away in 3D:

The analysis

procedure is then similar to what you do in Xflr5 but has more advanced

functions.