SHAPE3D X

User Manual

Version 9.1.2.6

01/10/2024

SHAPE3D X

User Manual

Version 9.1.2.6

01/10/2024

You can download the Shape3d installer (PC or Mac) at Download page. You need to Login first!

The Shape3d installer for PC is a .exe file like Sh3dX_9120.exe. It works Windows 7 to 11.

To start the installation double-click on the exe file. Then this window will pop up:

Click Next and then check I accept... to accept the user agreements.

Then keep clicking Next until you get the Finish button. You're done then!

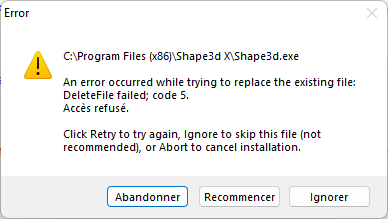

If you get this error message it means that Shape3d is already open on your computer.

Close all the instances of Shape3d on your computer and then start again!

The Shape3d installer for Mac is a .dmg file like Sh3dX_9120.dmg.

Note that the different versions of Shape3d don't work on all OS versions!

For exemple for the OS Captain or Sierra you'll need version 9.1.0.2, the more recent versions won't work.

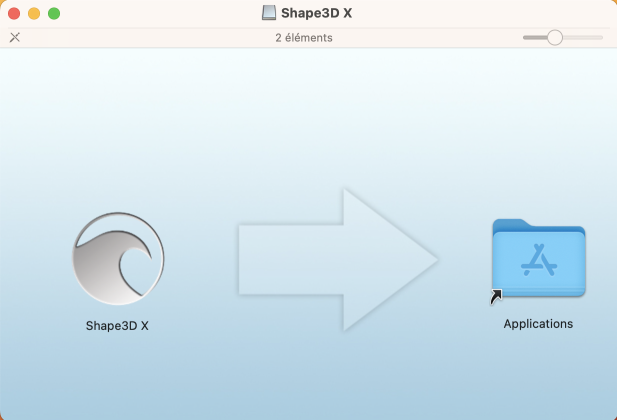

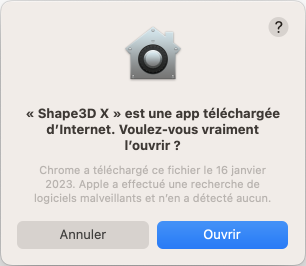

To start the installation double-click on the dmg file. Then this window will pop up:

Drag the Shape3d logo and drop it on the Application folder.

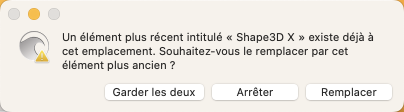

If Shape3d has been installed before a window will pop up to ask if you want to replace the previous version. Click Replace then.

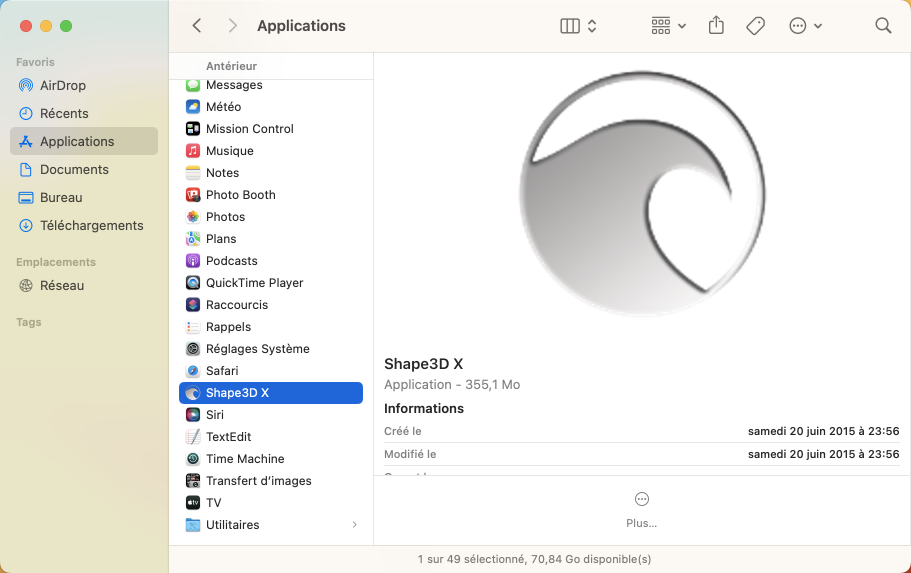

Once it's finished, go to the Applications folder and you'll see the Shape3d X appication. Double-click on it to launch Shape3d.

The first time you'll be asked if you realy want to open Shape3d X as it is a downloaded application. Click Open.

You can choose to keep the Shape3d X logo in the Dock to open Shape3d easily next time.

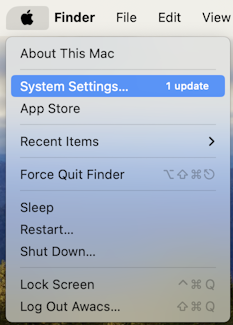

If your Mac doesn't allow you to install Shape3d then you need to check the "Privacy & Security" parameters in the "System Settings...":

In the panel "Allow applications downloaded from" you need to tick "App Store and identified developers":

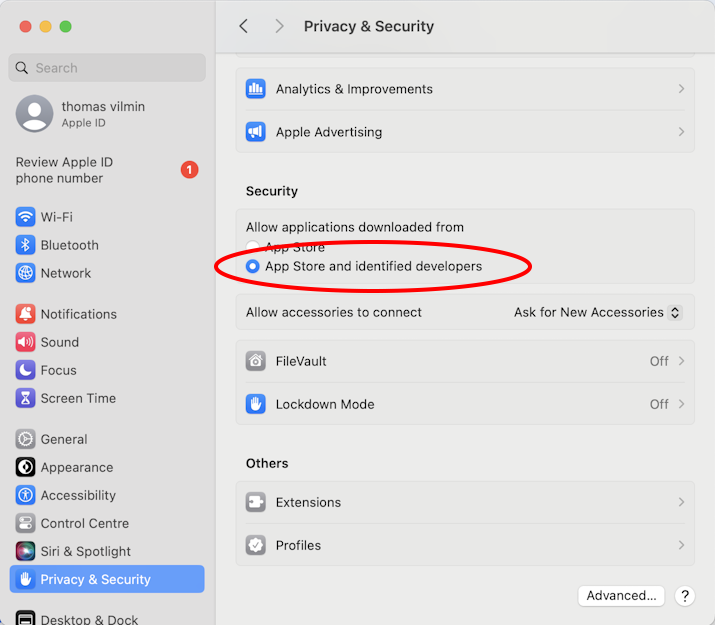

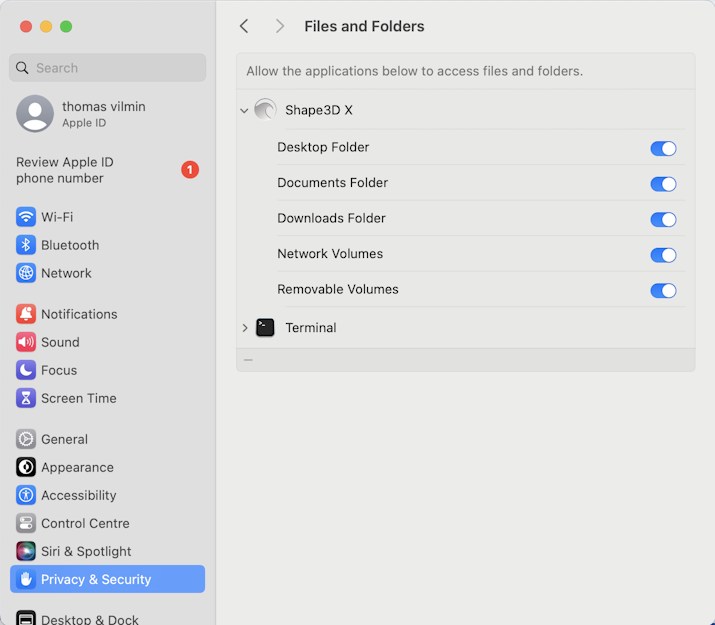

If you can't find your files in the Shape3d File Selector or the file browser, then you also need to verify the parameters in "Privacy & Security"/"Files and Folders":

Shape3d X must have access to all your folders:

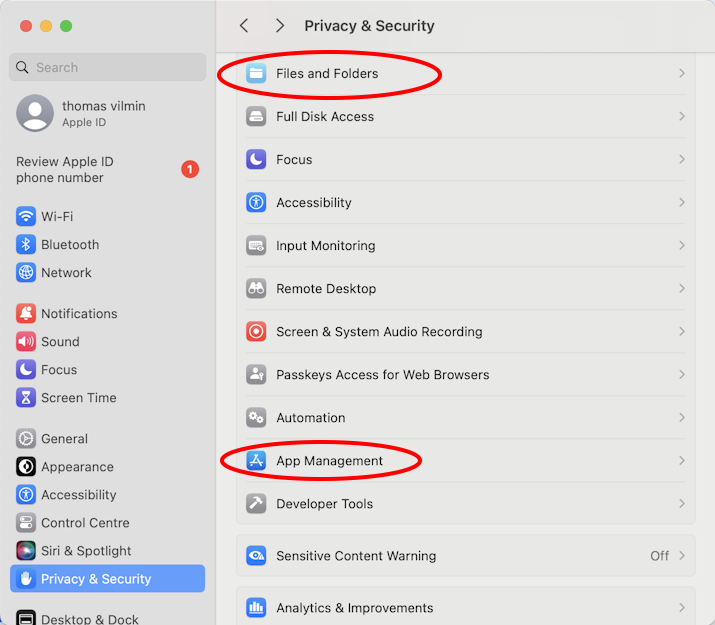

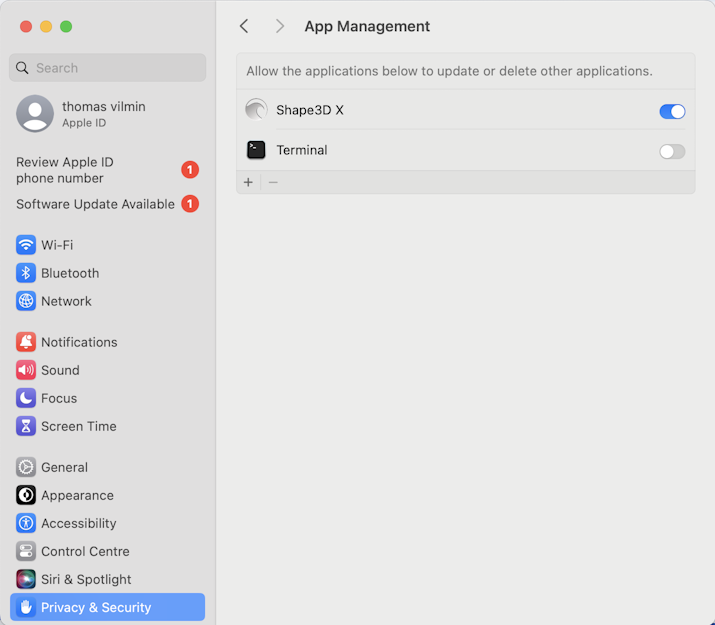

If you're experiencing repeated crashes of Shape3d you should also look at the "App Management" parameters and allow Shape3d X to update or delete other applications:

For any other problem with the installation of Shape3d X on your Mac check the FAQ: www.shape3d.com/FAQ.aspx

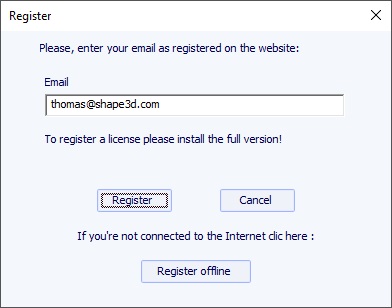

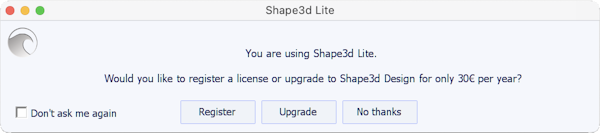

The first time you launch Shape3d Lite after installation, the following window will pop-up:

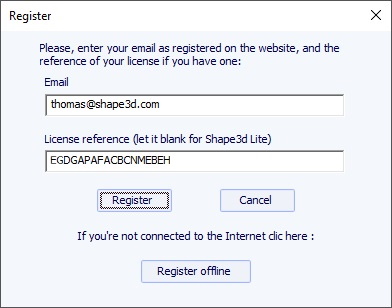

If you are connected to the Internet, enter your Email( and let the License Reference blank if the field is displayed).

Then click on the Register button.

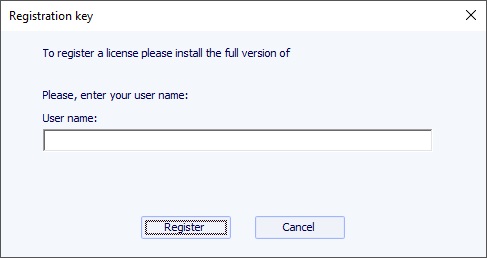

If you don't have access to the Internet, click Register offline to get the following window:

Enter a User Name (and let the Registration key blank if the field is displayed). Then click on the Register button.

If you have Shape3d Lite installed, you need to uninstall it and install the full version instead!

You can download the full Shape3d installer (PC or Mac) at Download page. You need to Login first!

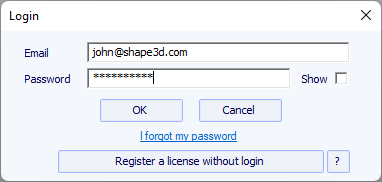

- If Shape3d has never been used on your computer, and if it has access to the Internet, the first time you open Shape3d you'll be asked to login. You'll need to use the same login (your email) and password you used when you created your account on our website:

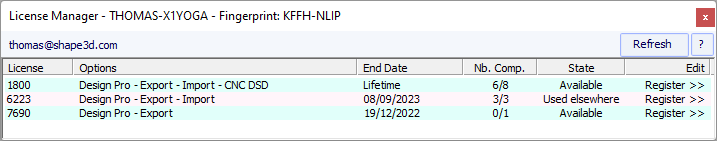

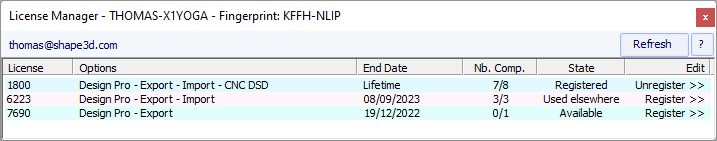

Once you're logged in the License Manager will open, showing the list of your valid licenses:

Just click on Register>> to activate your license. That's it, you're all set!

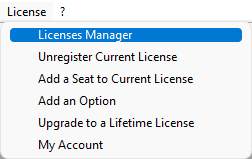

- If you installed Shape3d before without registering a license, the login window won't pop up. Then go to the menu License and click on the item License Manager.

Then you'll be asked to login and you can follow the instructions above.

- If you registered earlier a license that has since expired, then at the opening of Shape3d you'll be asked to either Register or Upgrade:

If you renewed your license on our website, or purchased another one, then press Register to be redirected to the License Manager and activate it.

If not, press Upgrade to be redirected to our website and renew your license, or purchased another one.

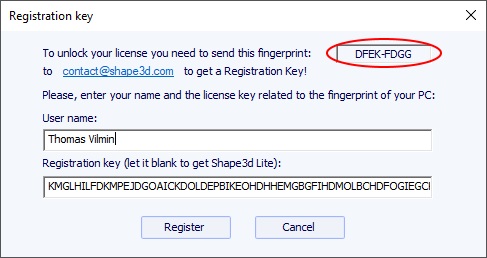

If Shape3d can't access the Internet, you'll need to follow the Offline registration procedure. The offline registration window will give you the Fingerprint of your computer:

Select and copy the Fingerprint in the clipboard,

and send it to contact@shape3d.com.

We will send you back the unlock key by email as soon as possible.

Once you have receive it, enter your user name as given in the email, and the unlock key.

The key is pretty long, so do a copy-paste if possible to avoid mistakes. Make sure the fingerprint is still the same, as it can change in some circumstances.

If you want to use a license for which you have the reference, and the account email but not the login password, you can activate the license pressing the button Register a license without login in the Login window:

Enter the account email and the license reference and click on the "Register" button.

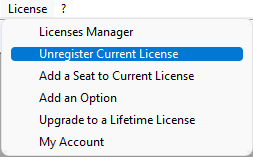

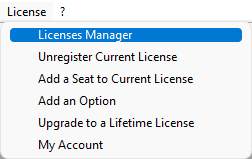

If you want to tranfert your Shape3d license to a new computer you'll have to unregister it from your actual computer first. For that, go to the menu License of Shape3d, and click Unregister Current License:

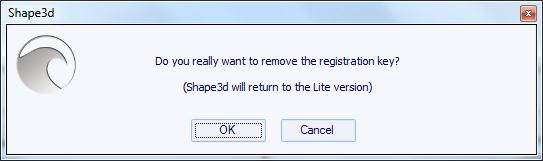

Shape3d will ask you to confirm that you want to remove the registration key.

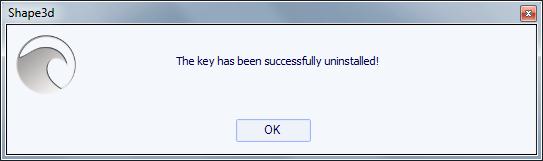

If you're connected to the Internet, this will also remove the computer fingerprint from our database, so you can register your license on another computer straight away. You'll see this confirmation window then:

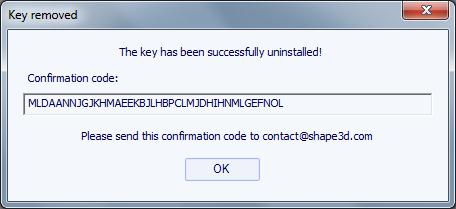

If you're not connected to the Internet, you'll see this window that contains a Confirmation Code. Send us this confirmation code at contact@shape3d.com so we'll know that you no longer use Shape3d on this computer and that you can register your license on another one:

Shape3d will then revert to Shape3d Lite.

Note that if you have several licenses registered on your computer and you only want to unregister one of them, you can do it from the License Manager.

Then, you can register your license on your new computer using the License Manager as explain above.

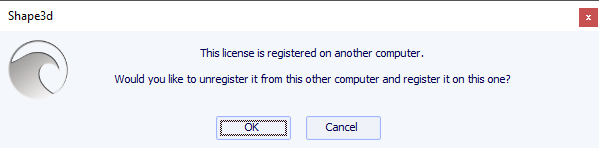

If you couldn't unregister your license from your old computer, you can still do it from your new computer,

provided Shape3d can access the Internet, and the old computer hasn't been used for the past 2 hours.

Open Shape3d on your new computer, go to the menu License and click on the item License Manager:

You'll need to login using the same login (your email) and password you used when you created your account on our website.

Once you're logged in the License Manager will open, showing the list of your valid licenses.

Click on Register>> at the end of the line showing the license you want to register:

Since the license has already been registered on your old computer, you'll be asked if you want to unregister the license from this other compter:

Press OK. This will automatically transfer the license to the new computer.

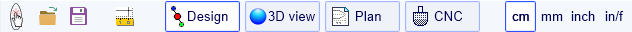

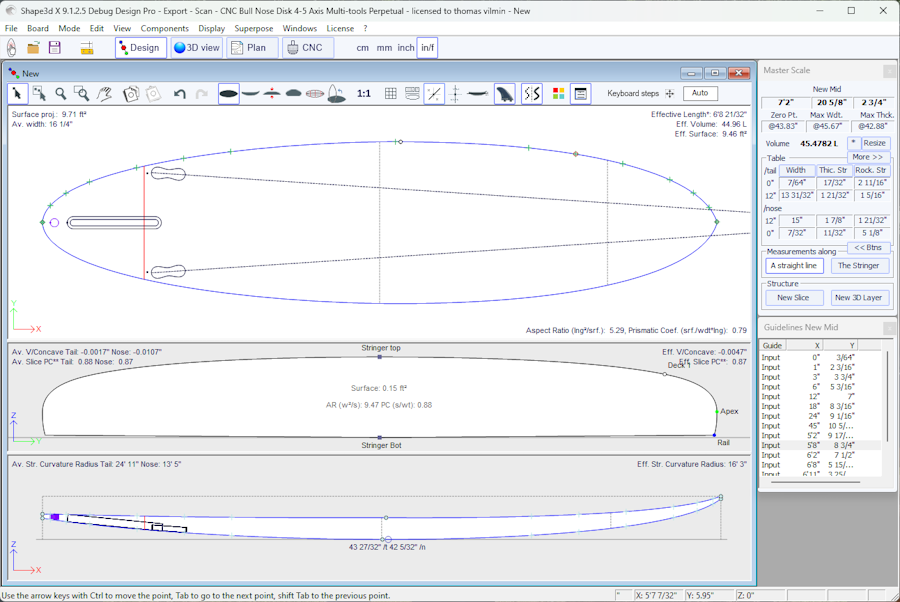

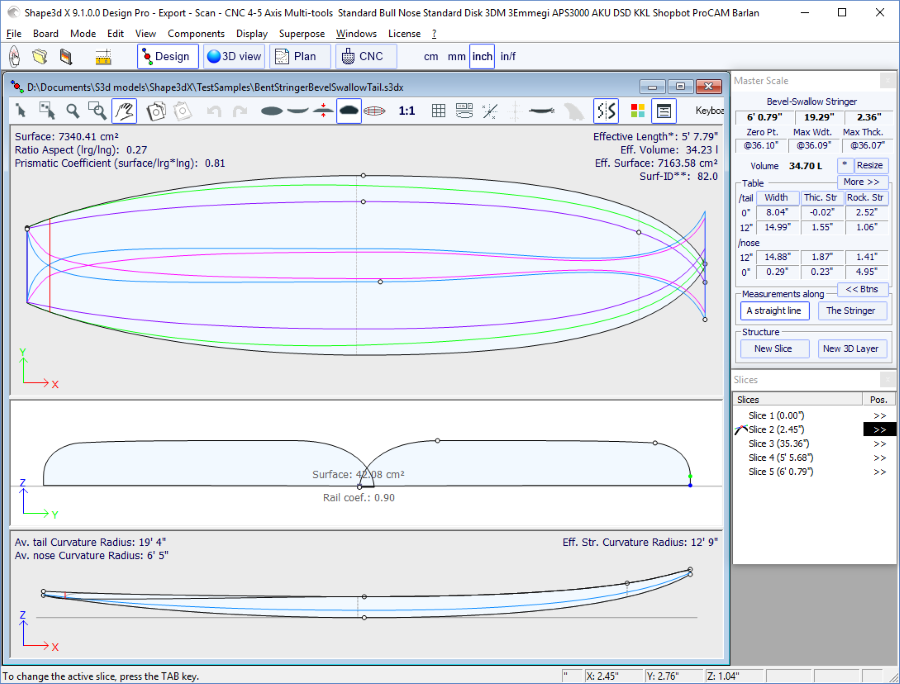

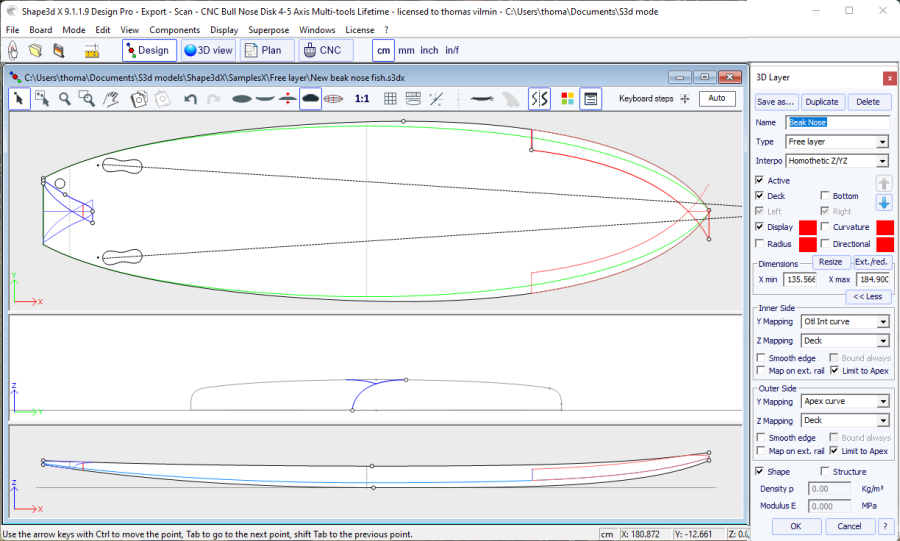

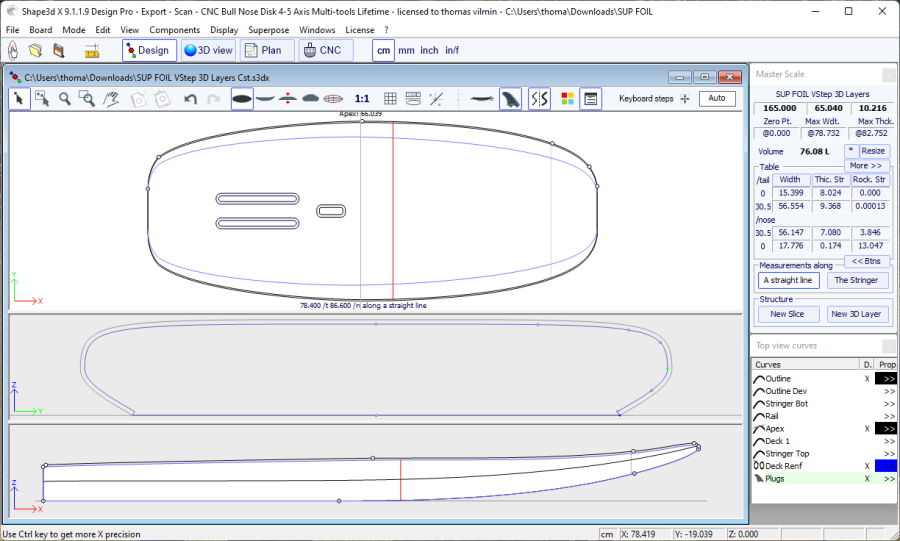

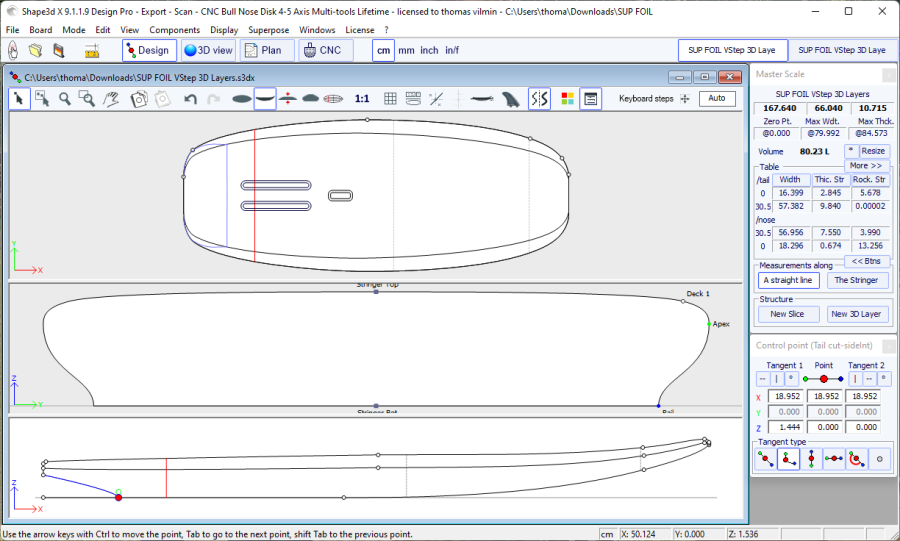

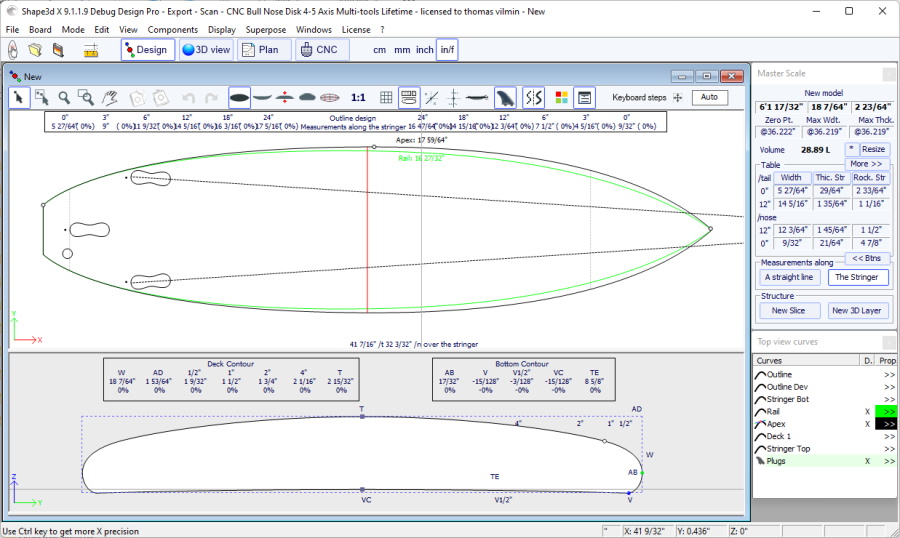

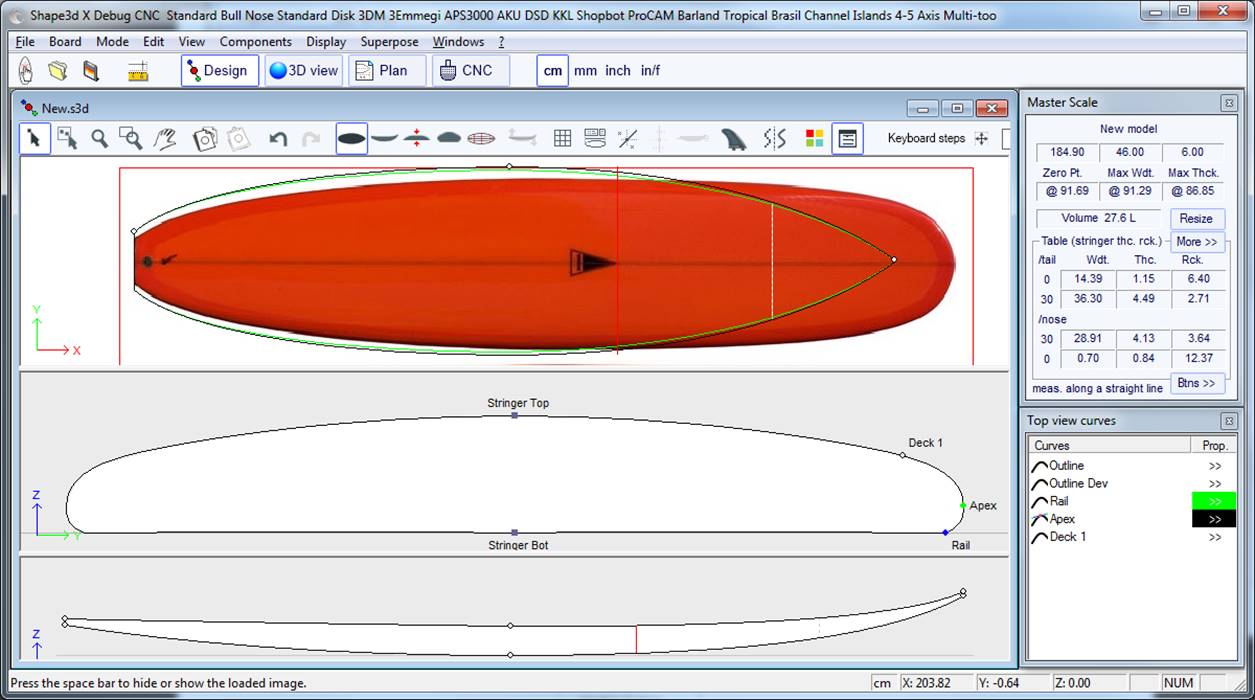

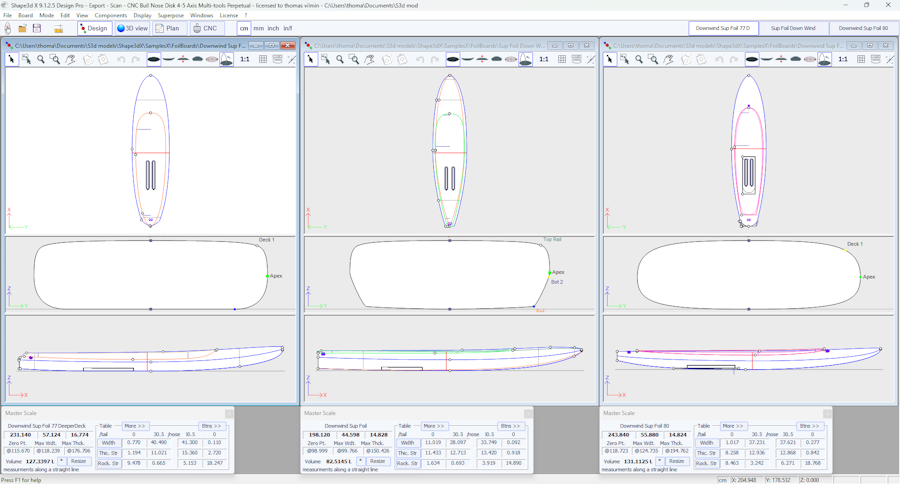

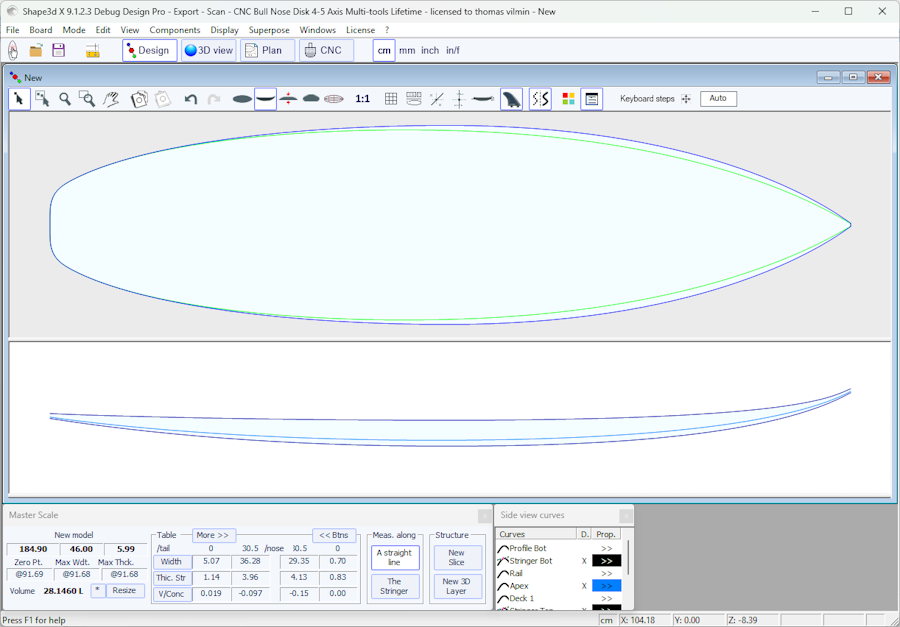

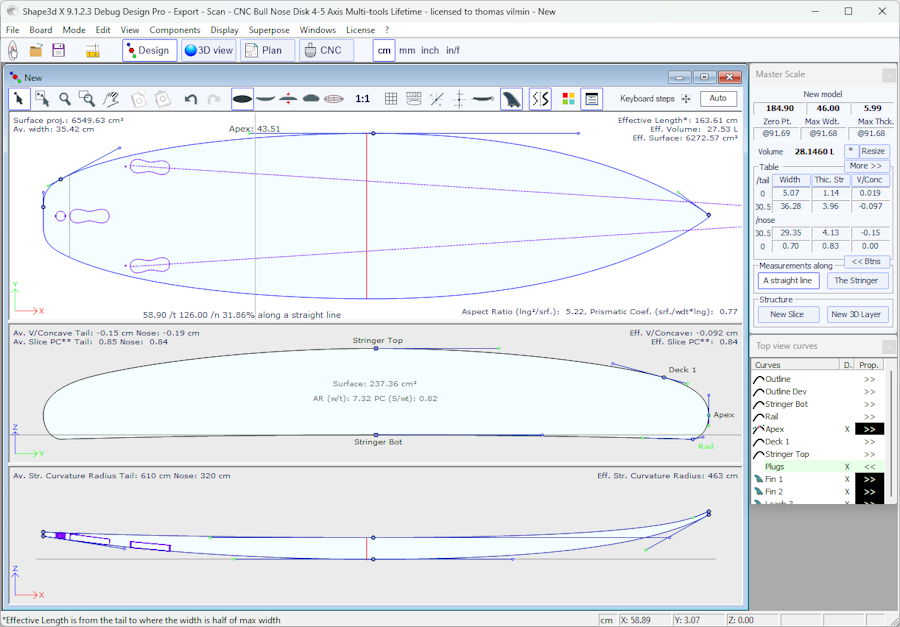

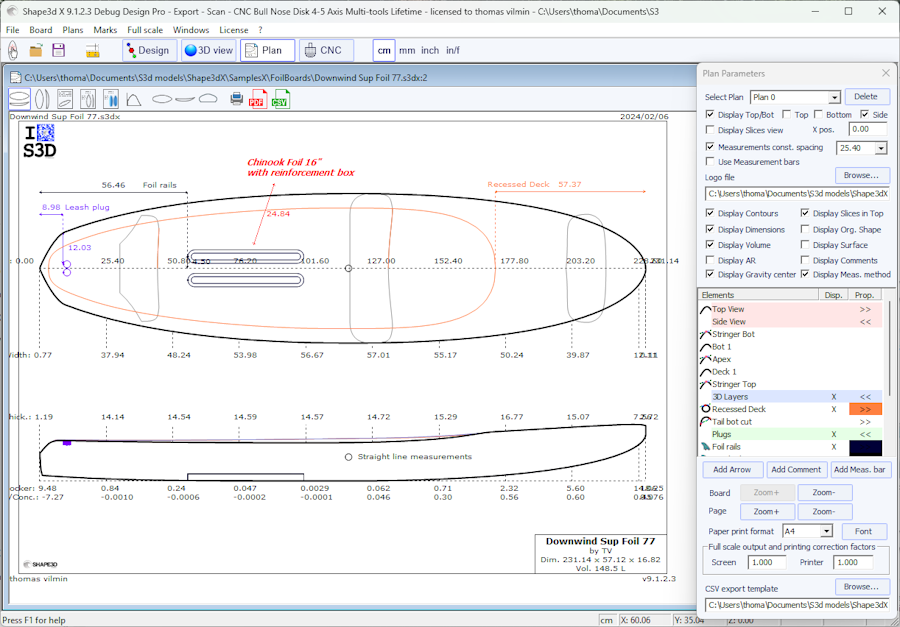

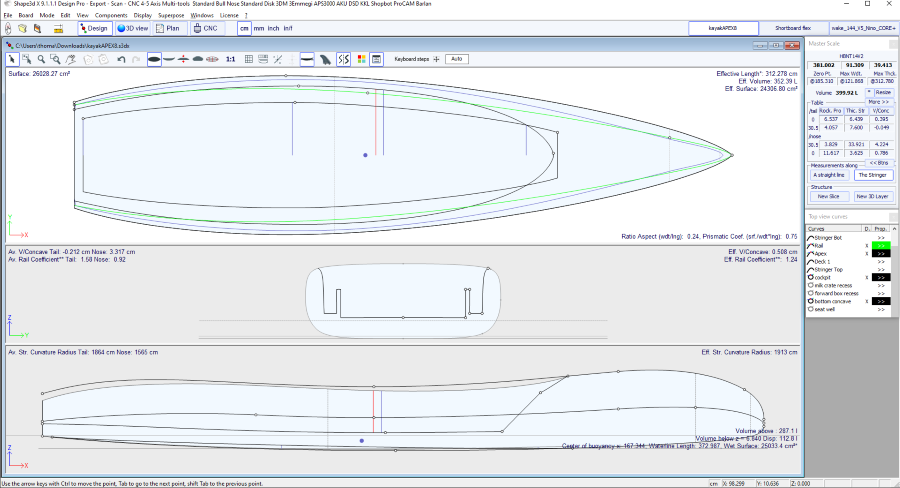

Shape3d presents four edition modes that can be selected in the general toolbar:

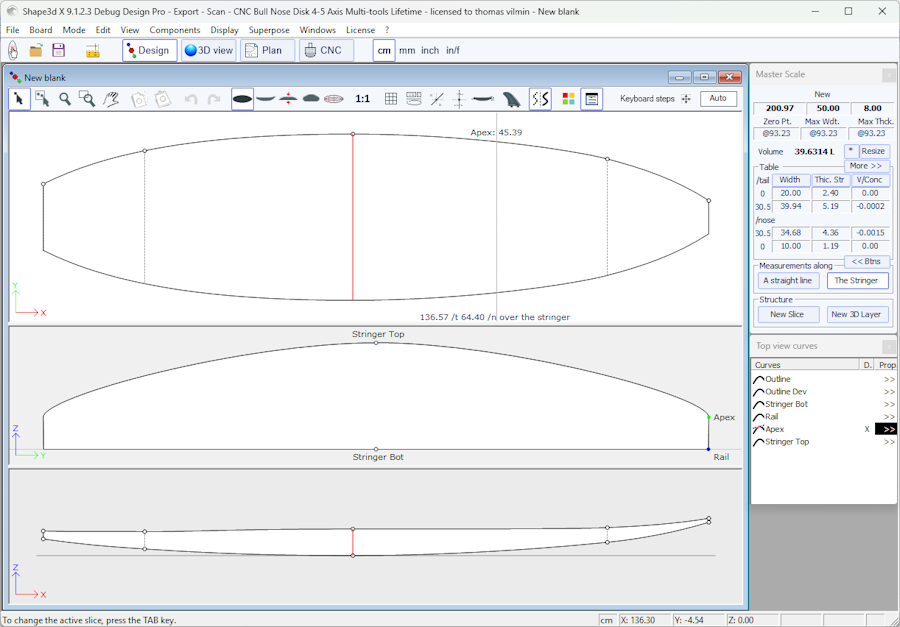

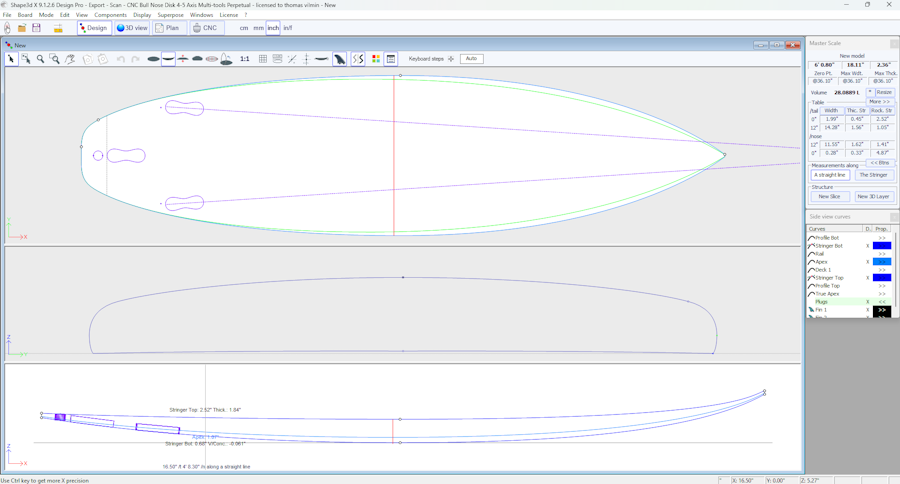

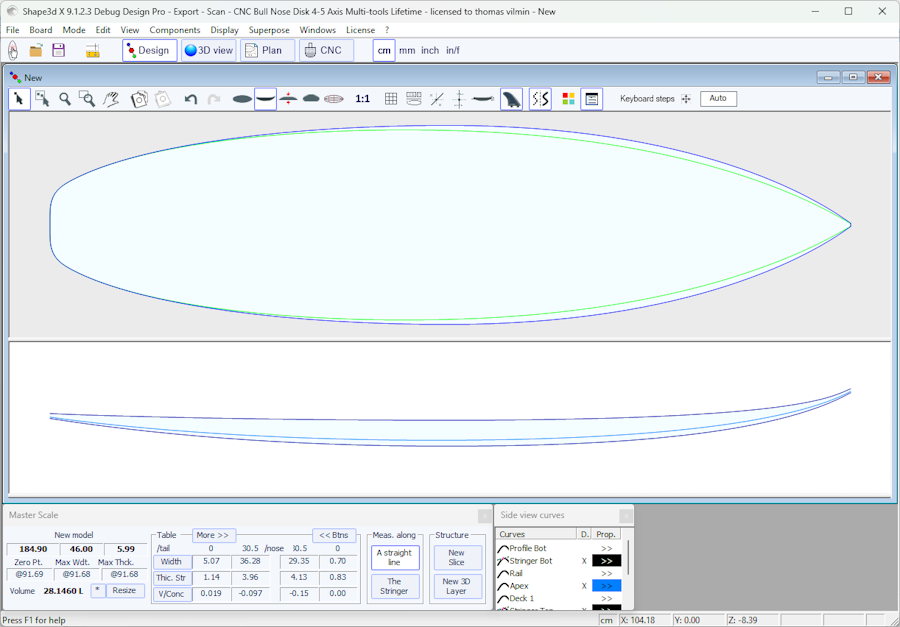

The Design Mode presents three 2D views of the boards that can be

the outline, the profile, the thickness or the slices. In each view,

the curves can be modified through the control points. The measures

of the board are shown in the Master Scale box.

The Design Mode presents three 2D views of the boards that can be

the outline, the profile, the thickness or the slices. In each view,

the curves can be modified through the control points. The measures

of the board are shown in the Master Scale box.

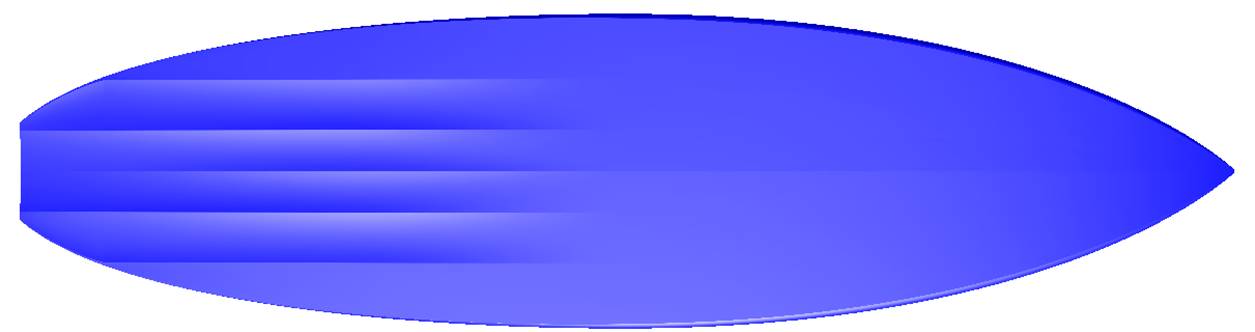

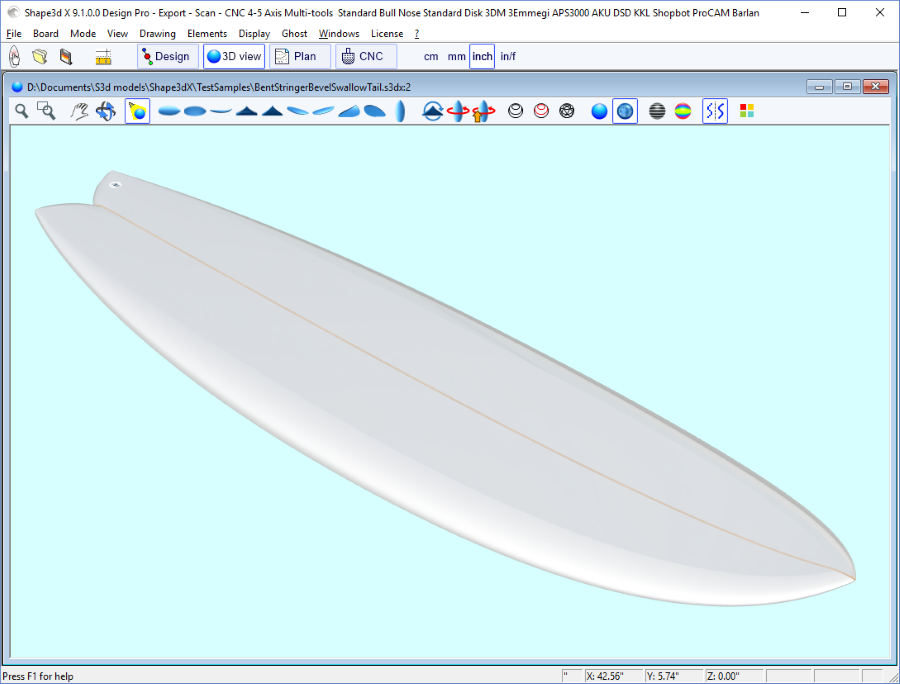

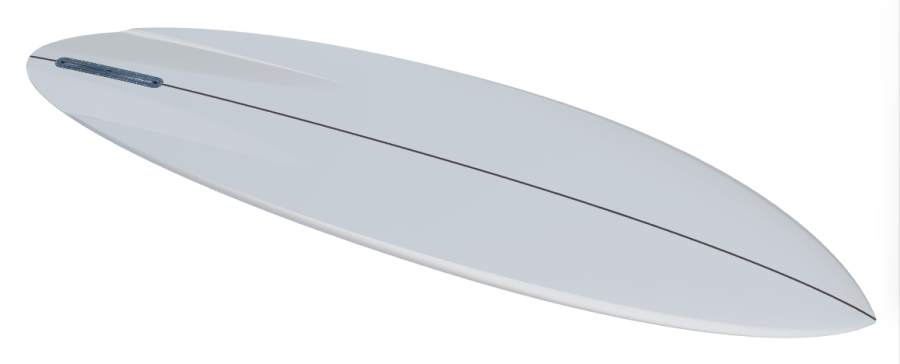

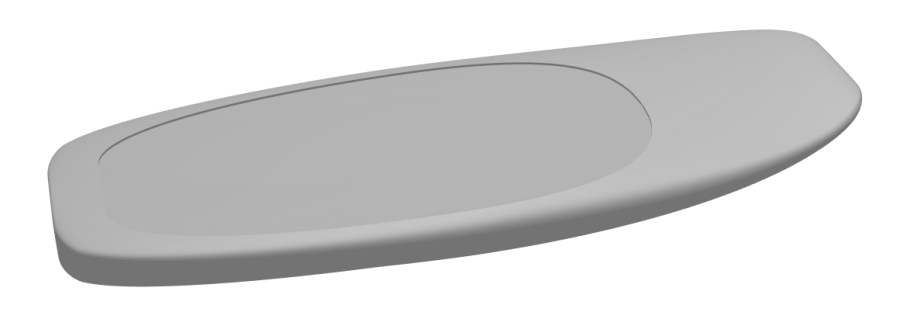

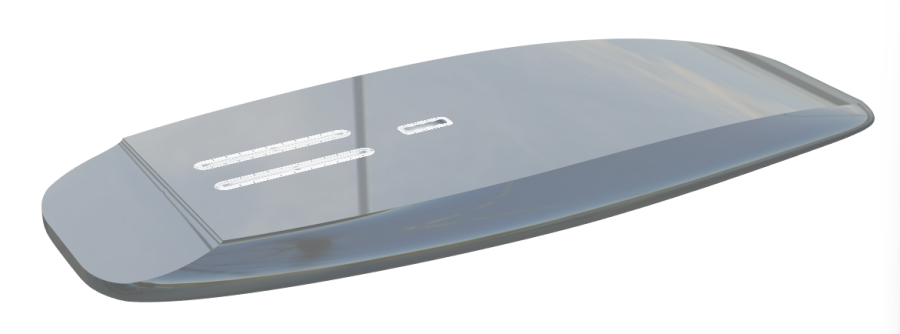

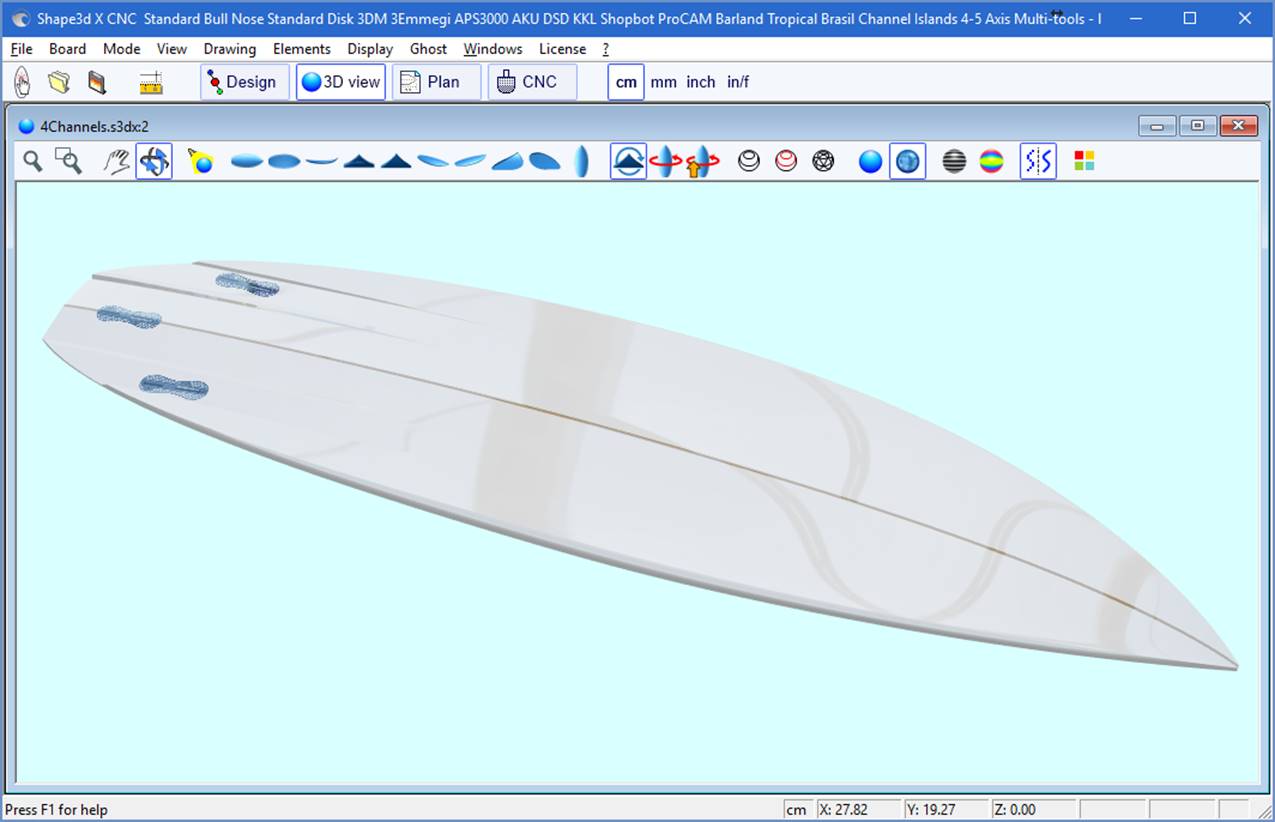

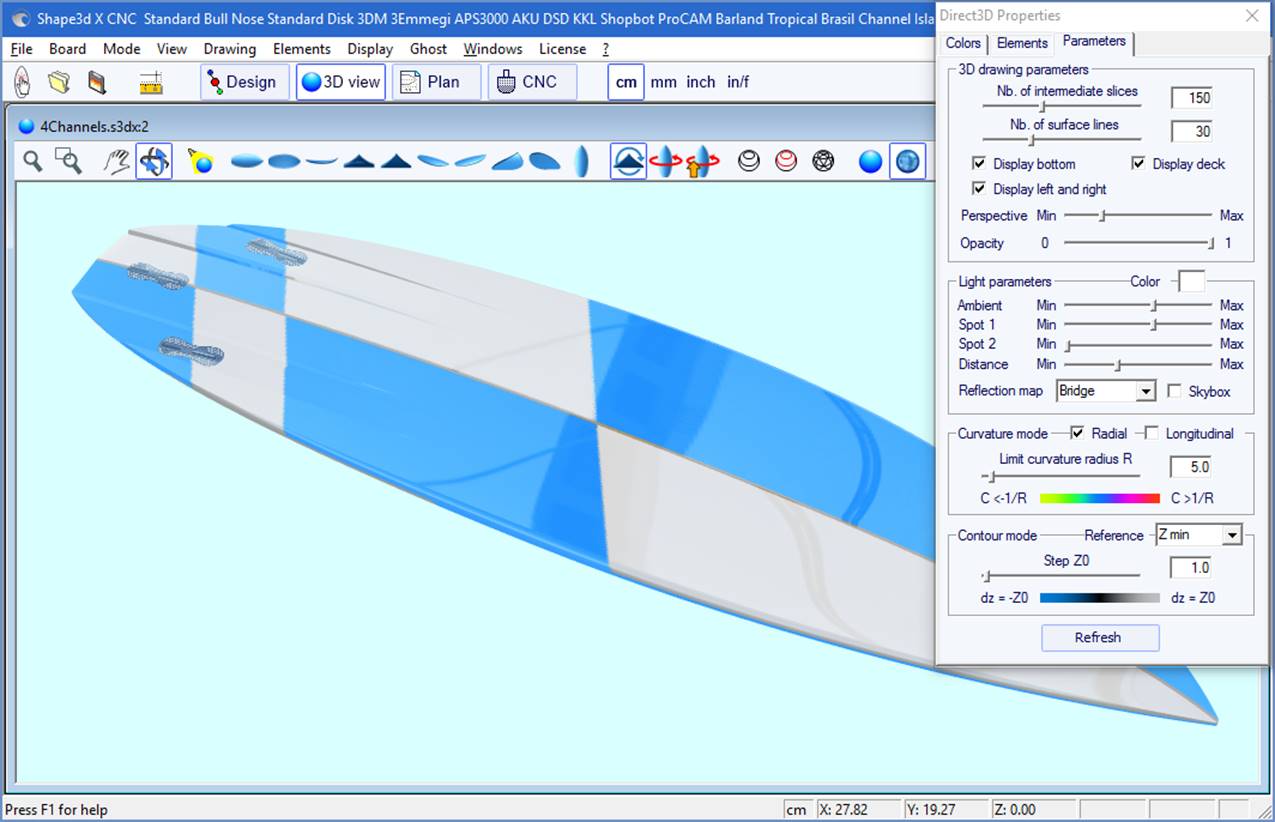

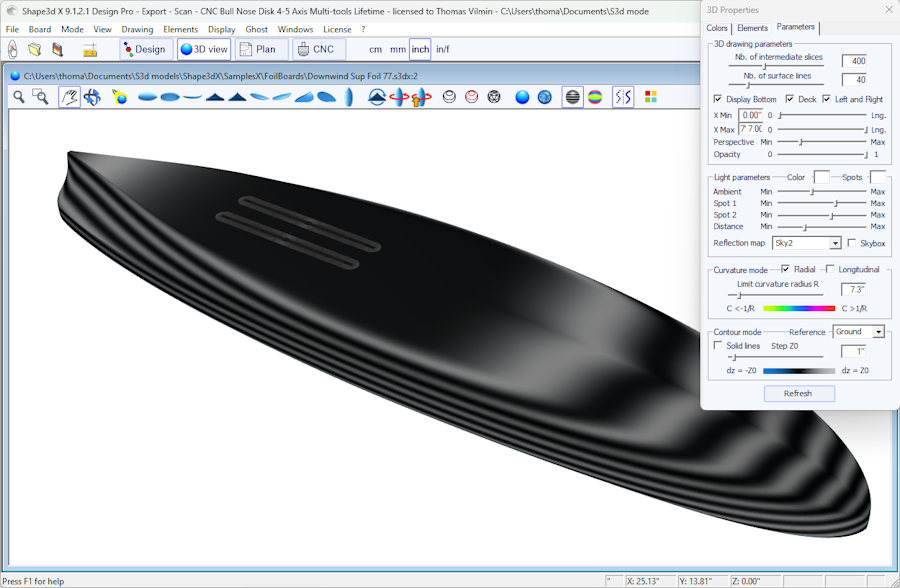

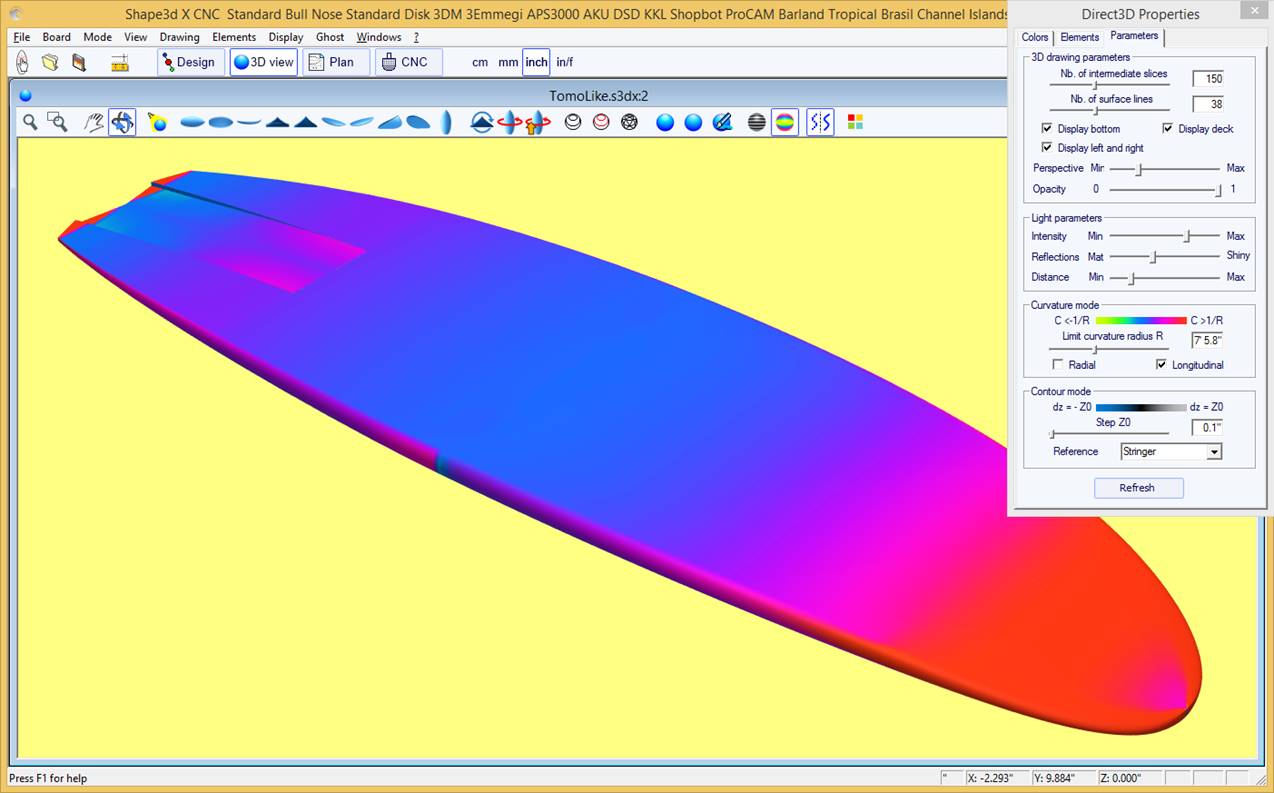

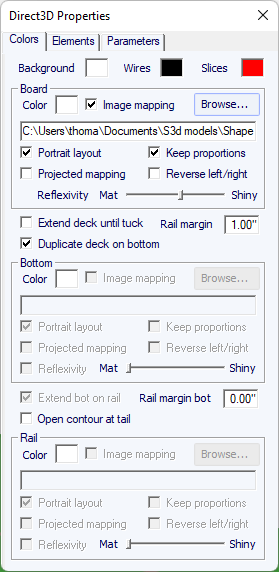

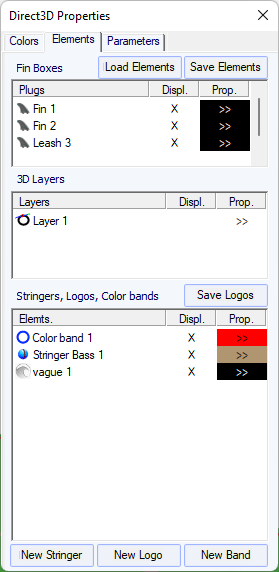

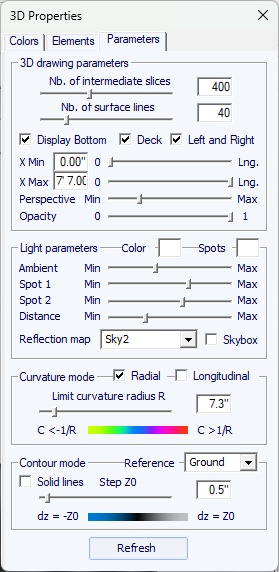

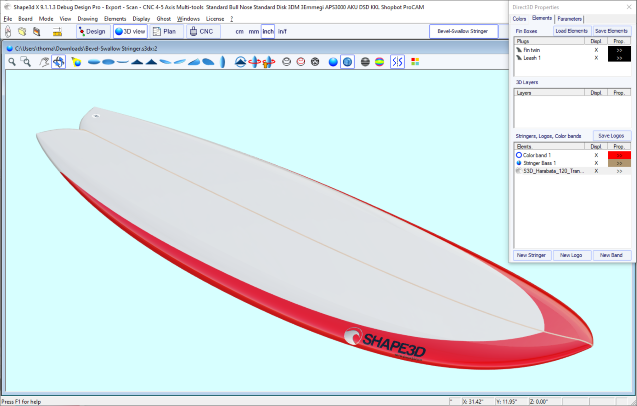

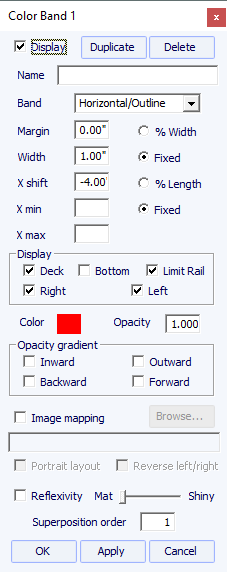

The 3D Mode allows the visualization of the boards as a 3D object,

either with a solid rendering or a wired rendering.

The 3D Mode allows the visualization of the boards as a 3D object,

either with a solid rendering or a wired rendering.

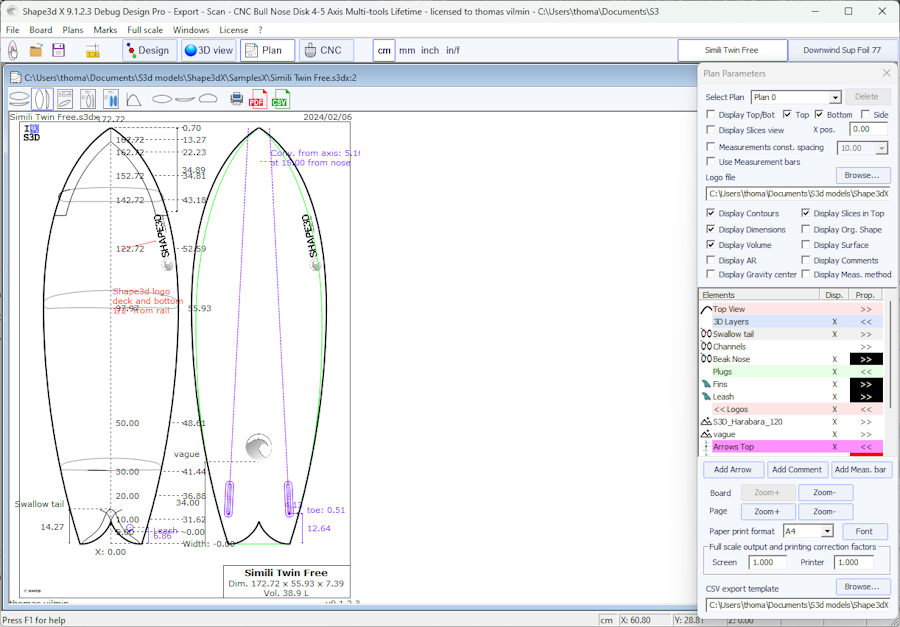

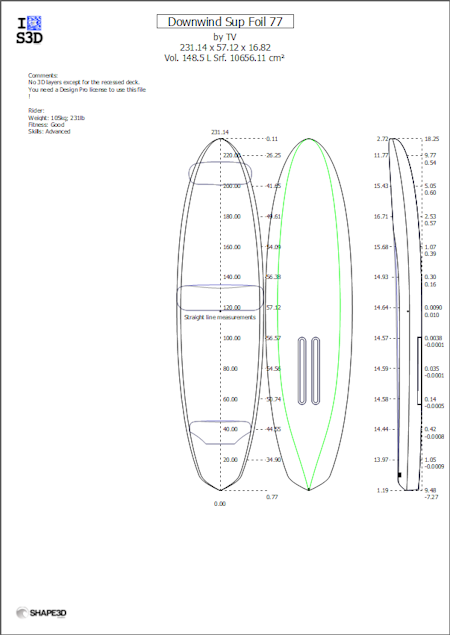

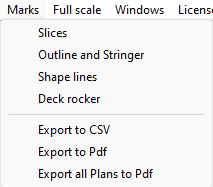

The Plan Mode displays board charts with measurements, and

full scale printable view of the board.

The Plan Mode displays board charts with measurements, and

full scale printable view of the board.

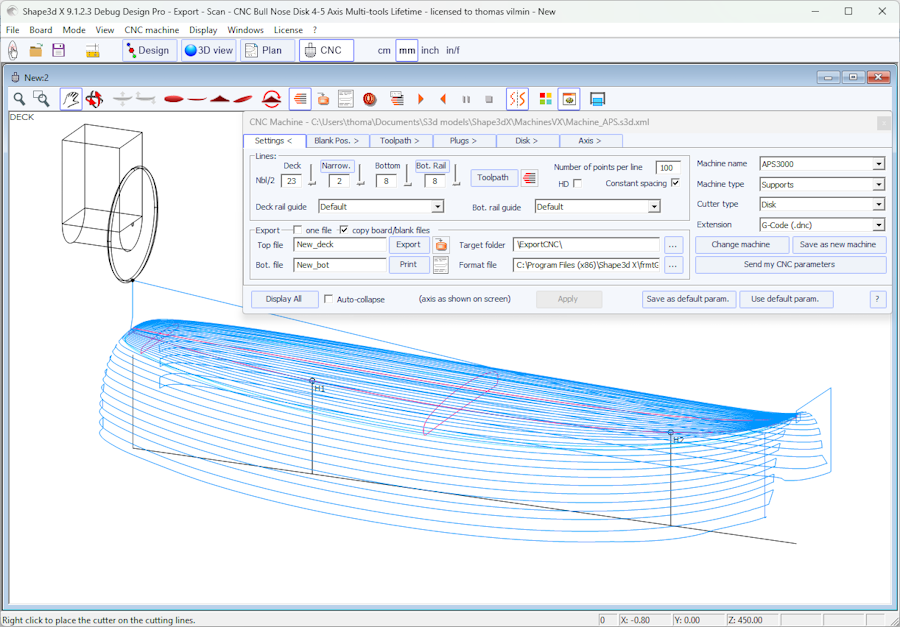

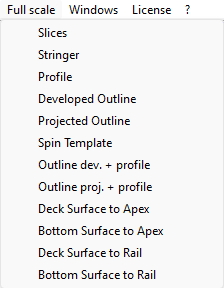

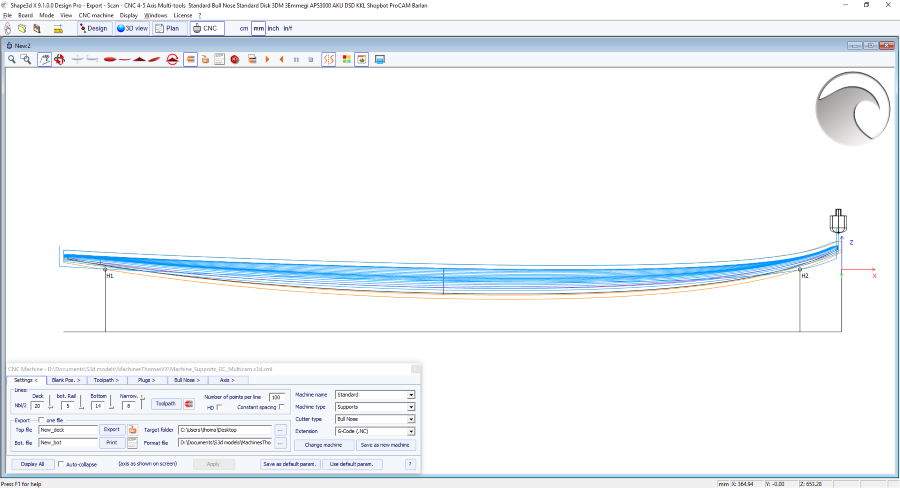

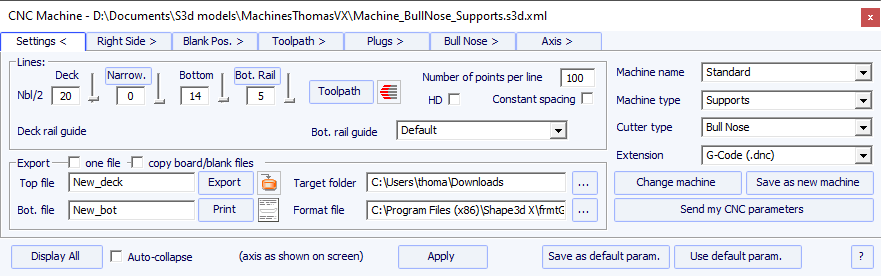

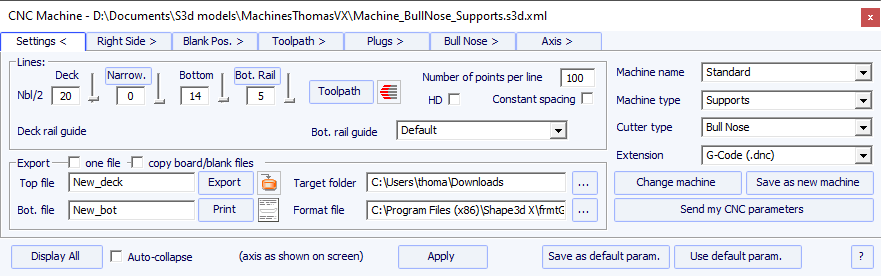

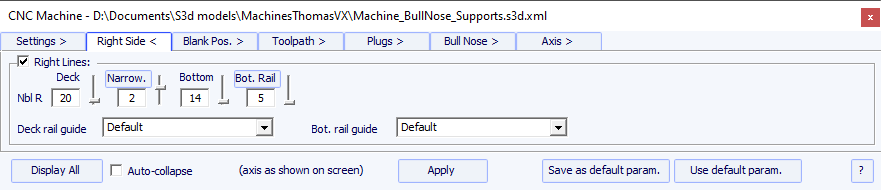

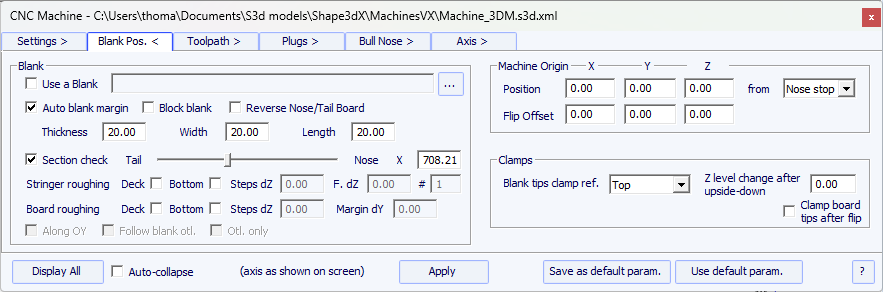

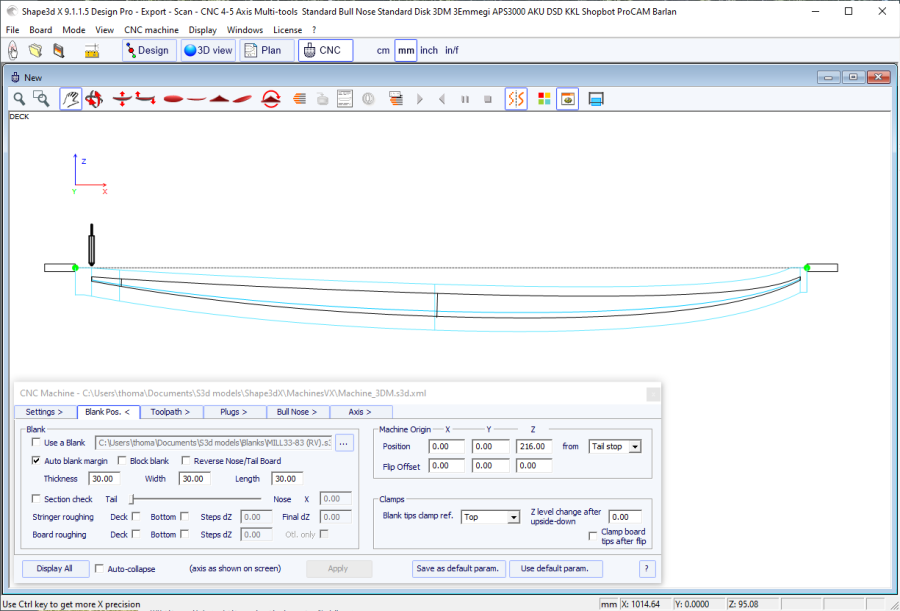

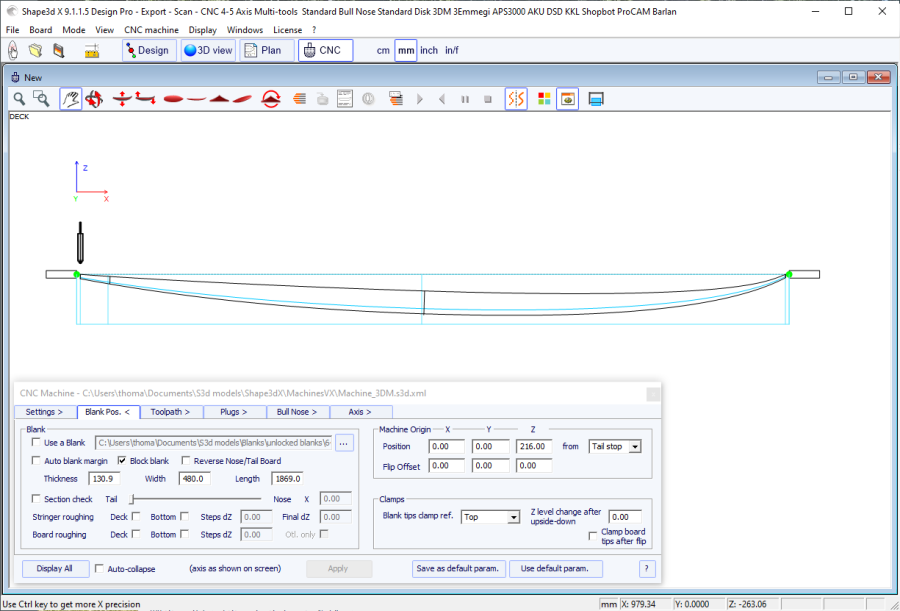

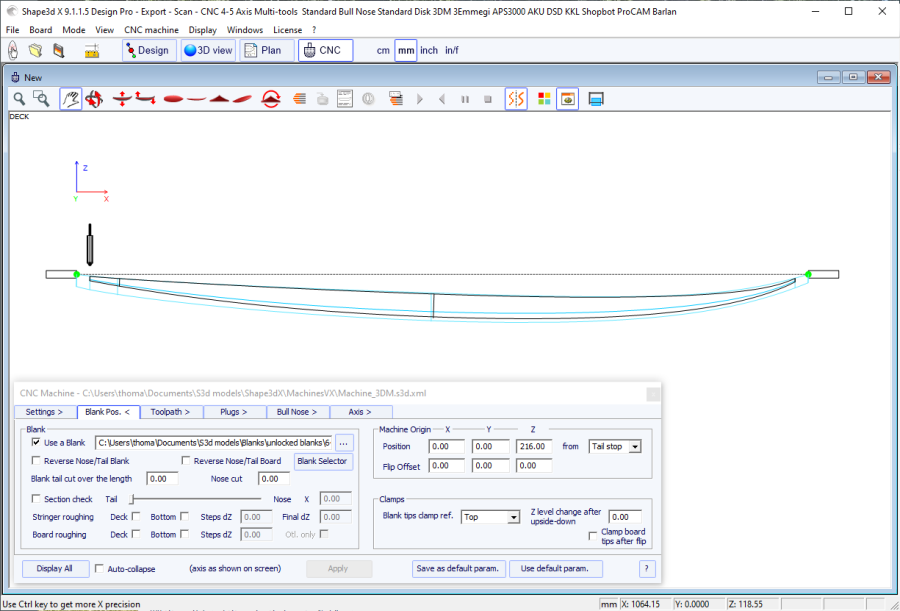

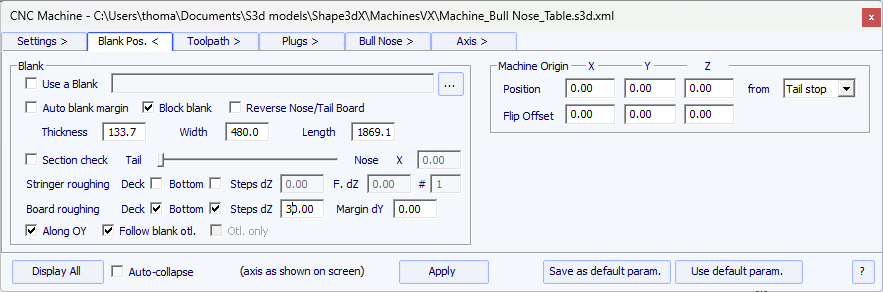

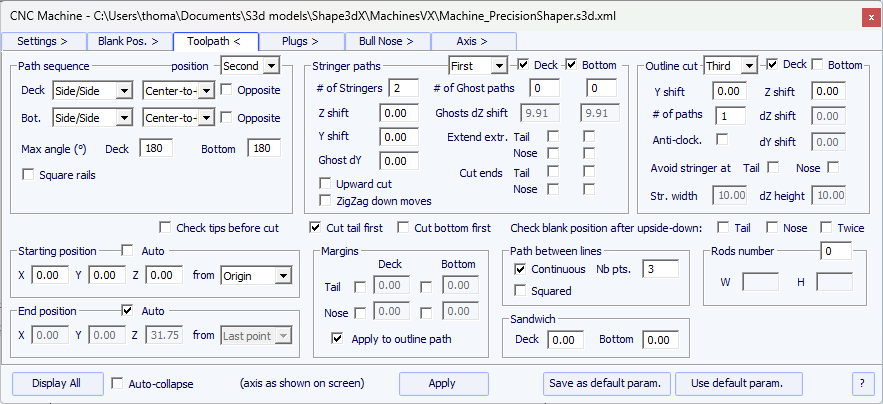

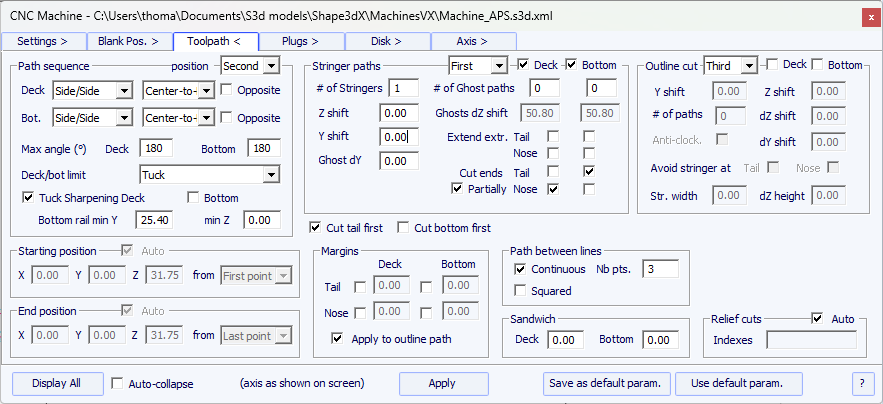

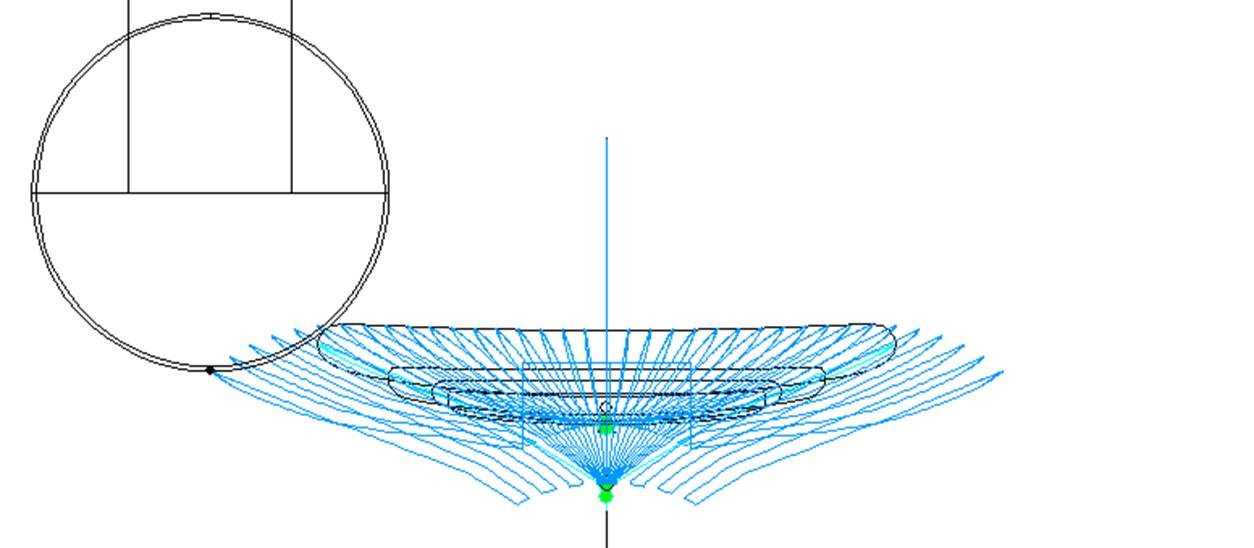

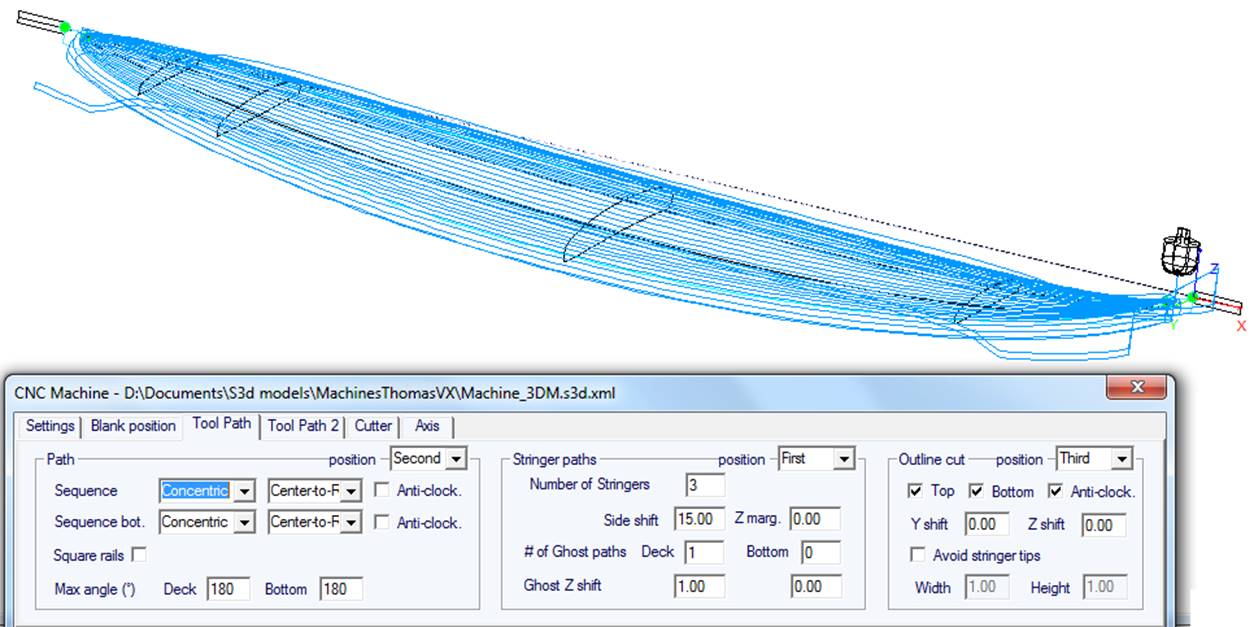

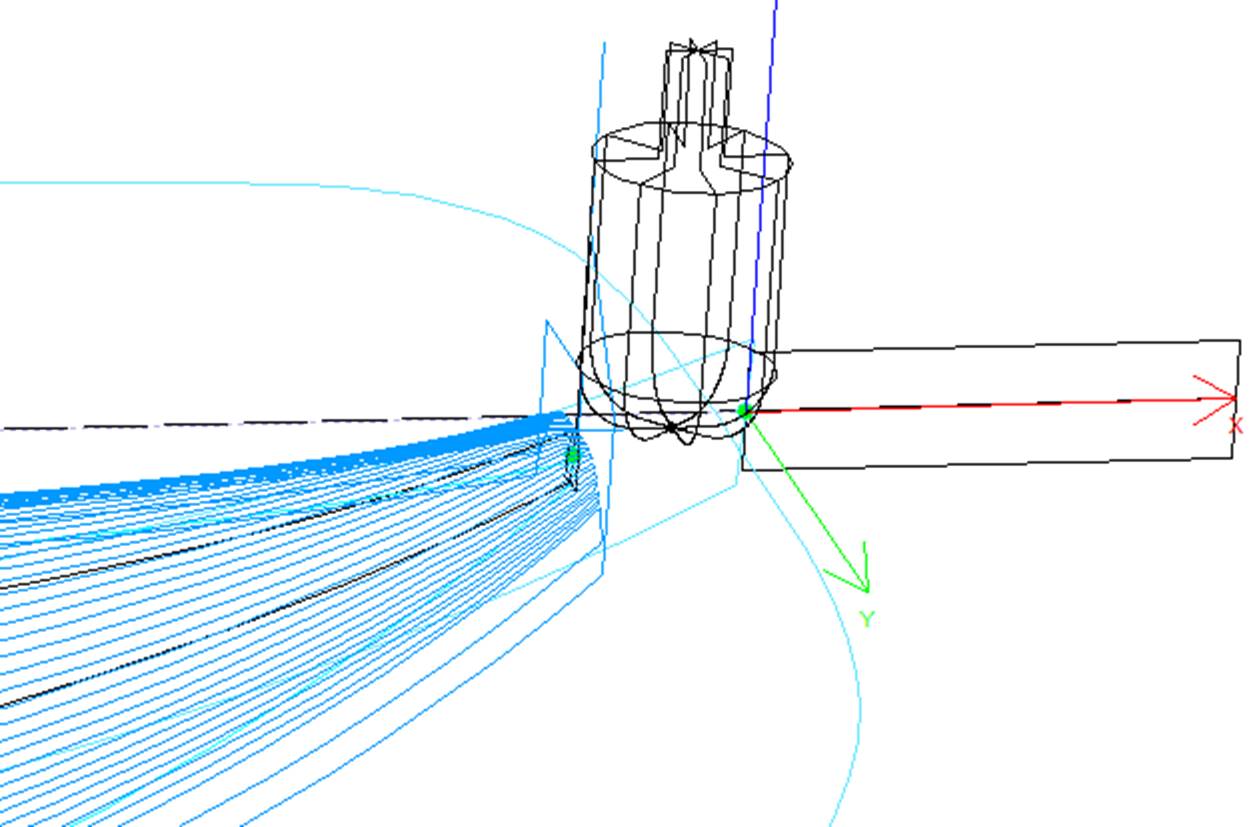

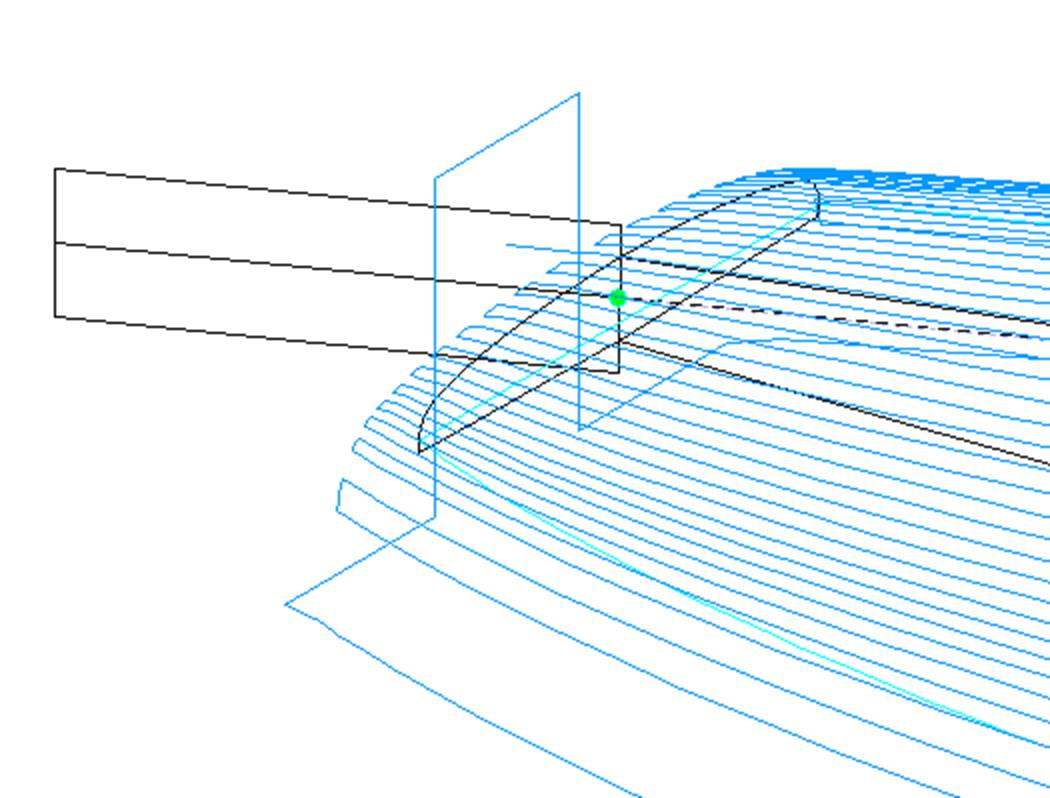

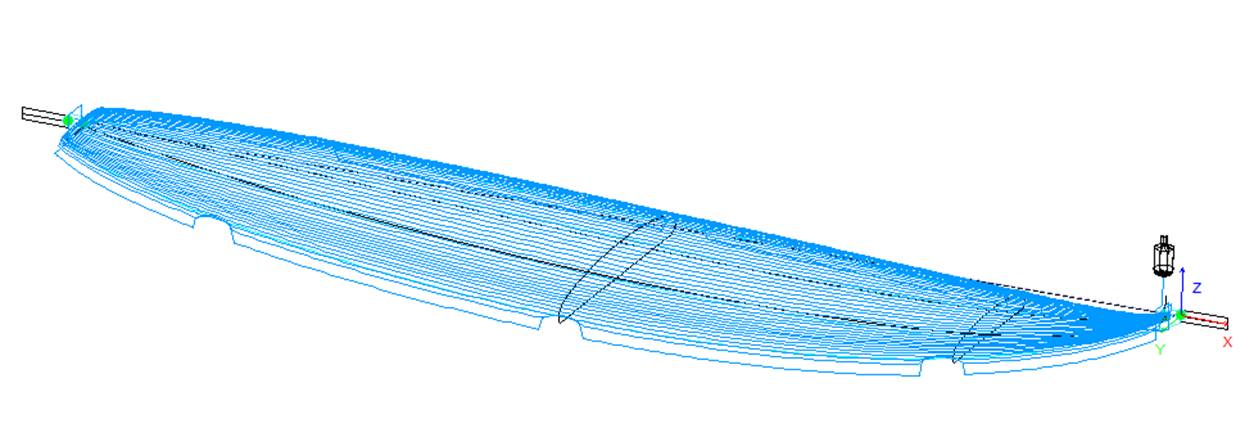

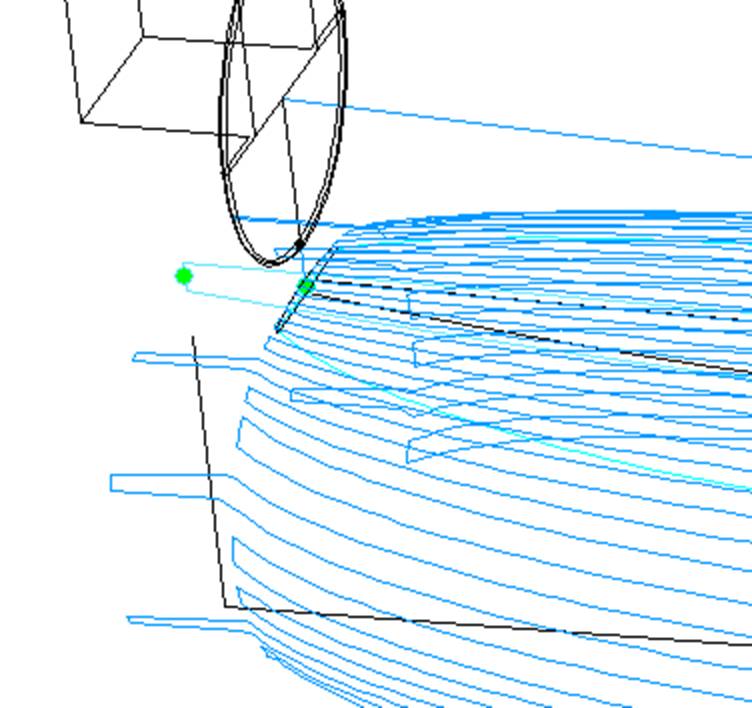

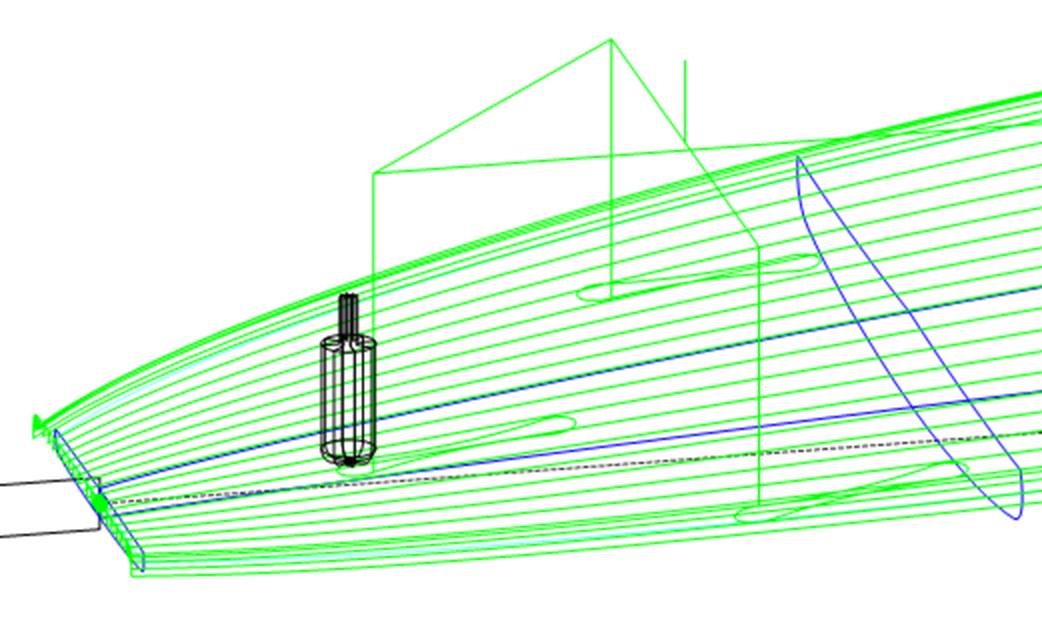

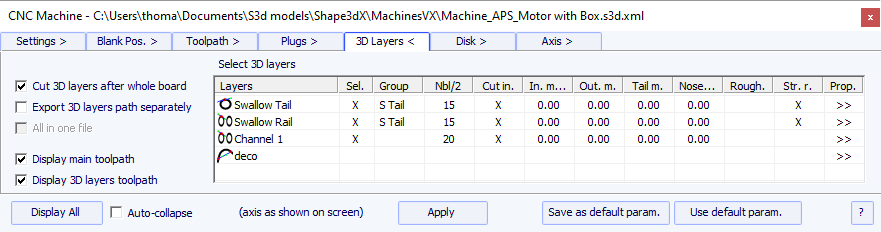

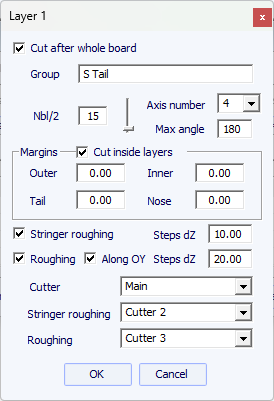

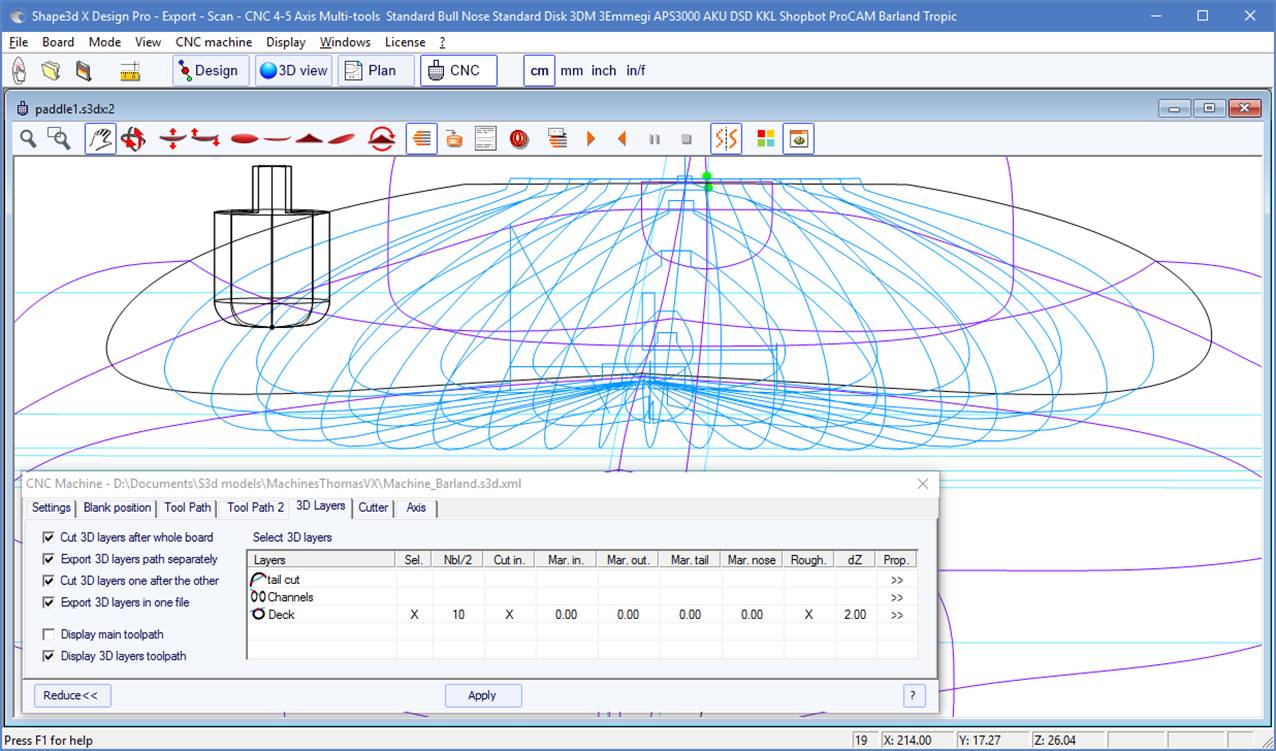

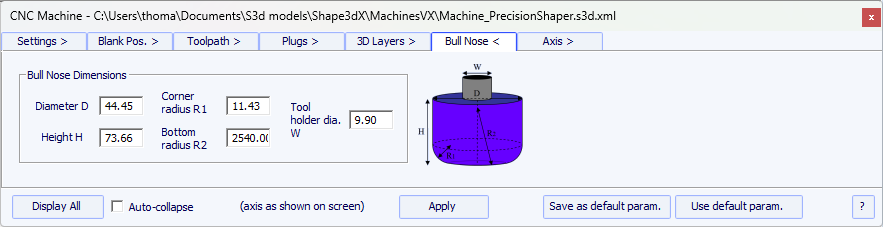

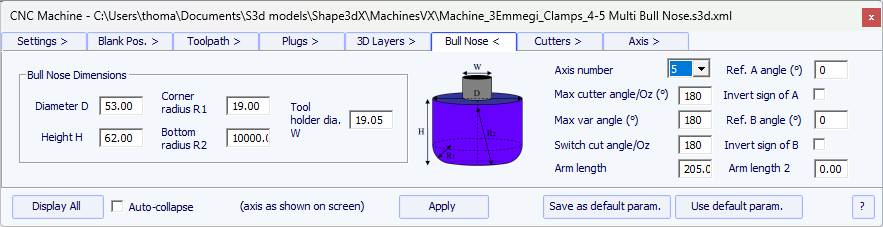

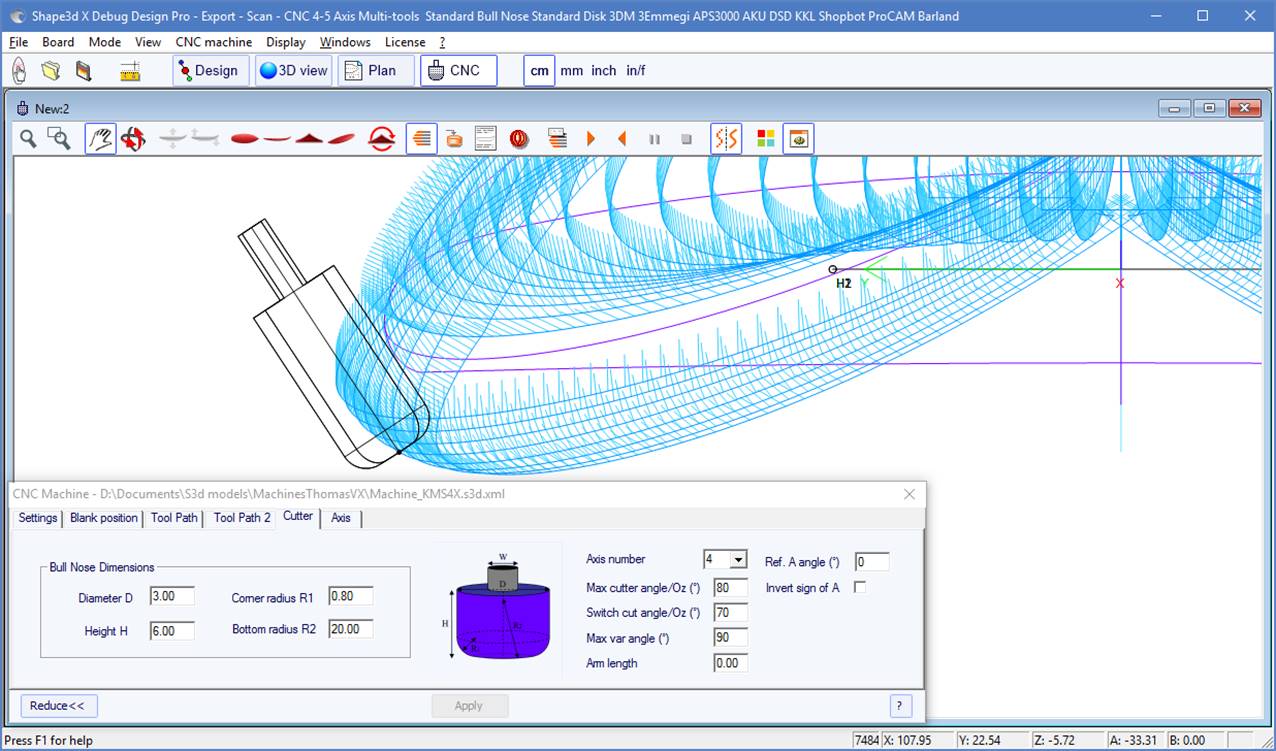

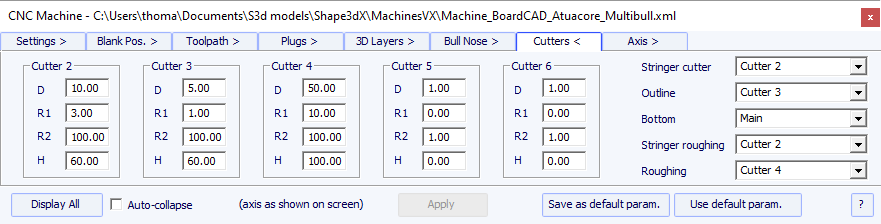

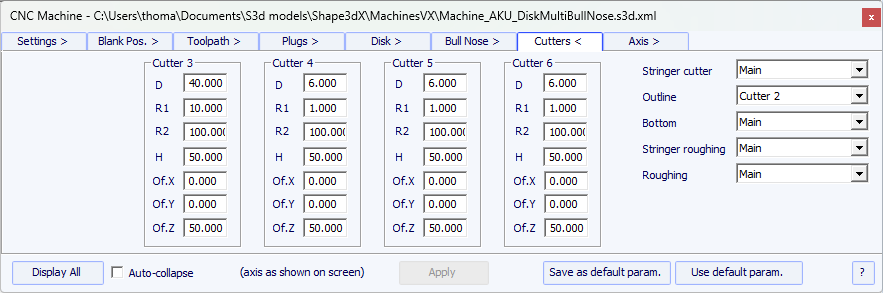

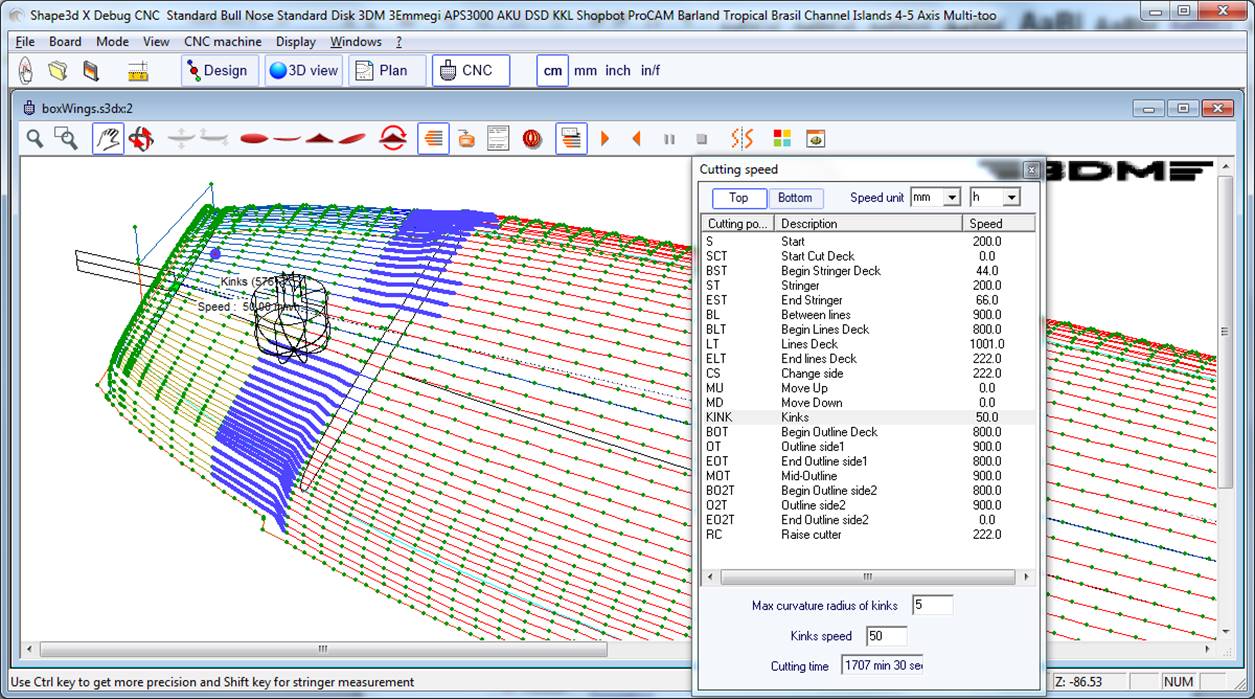

The CNC Mode presents all the settings of the CNC machine,

and allows to compute, and visualize the cutting path.

The CNC Mode presents all the settings of the CNC machine,

and allows to compute, and visualize the cutting path.

The general toolbar, which is accessible in each edition mode, also contains some general functions:

This button opens a dialog box that allows creating a new board from

an existing model or from measurements.

This button opens a dialog box that allows creating a new board from

an existing model or from measurements.

This button allows to open the file browser (or the File Selector) to load an existing file.

This button allows to open the file browser (or the File Selector) to load an existing file.

Save the current model.

Save the current model.

Open the "Size & Parameters" dialog box that allows to change

the dimensions of the board, as well as other properties that will

be presented farther down.

Open the "Size & Parameters" dialog box that allows to change

the dimensions of the board, as well as other properties that will

be presented farther down.

Select the measurements unit.

Select the measurements unit.

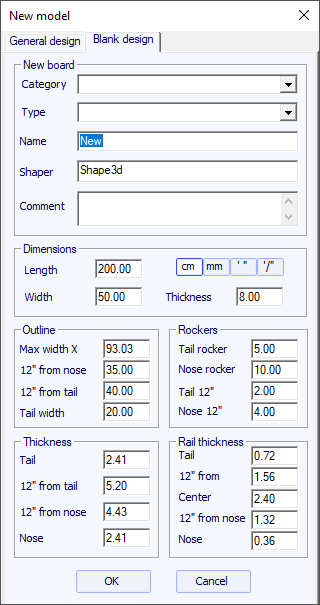

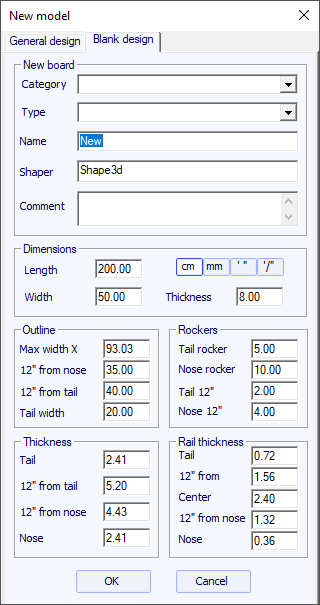

Go to the menu "File", then "New", or press the button "New" ![]() . The following window pops up.

. The following window pops up.

- The new model will start from a default file. You can define a different default file for each Category/Type of design (Surfboard/Shortboard, Longboard, Windsurf...). The default file when you install Shape3d is New.s3dx. Don't hesitate to change it to one of your own files!

- Enter the name of the model you are going to design, and your name as a shaper. Add any comments you want.

- Choose the dimensions' unit: centimeters, millimeters, inches or fractional inches.

- Check the box "symmetric nose/tail" for a twin-tip board. Uncheck "symmetric right/left" for asymmetric designs.

- Input length, width, thickness, and tail/nose rocker.

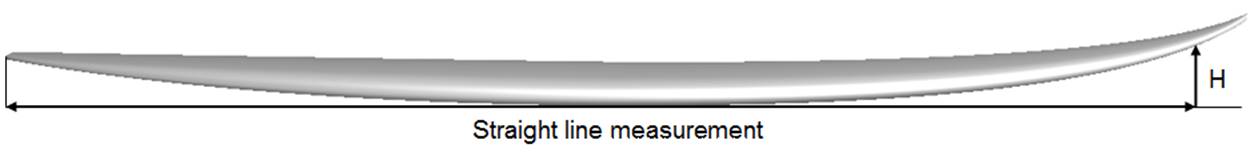

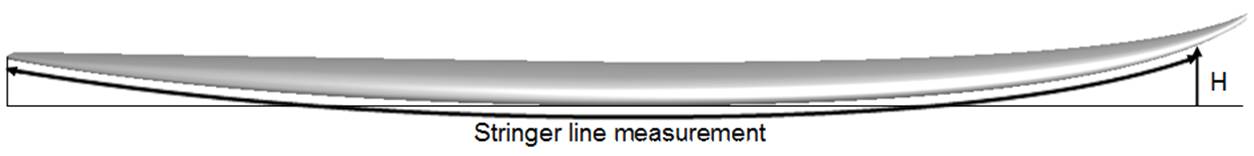

- Check the box "Stringer measurement" if these dimensions are measured along the stringer. Uncheck it if they are measured along a straight line.

- Press OK.

The starting model appears in the Design mode.

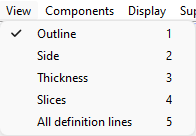

You can visualize three components of the board at the same time, choosing between Outline, Profile, Thickness, or Slices in the toolbar.

The dimensions of the board appear in the Master Scale box.

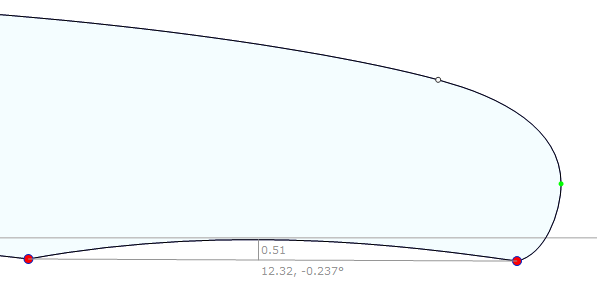

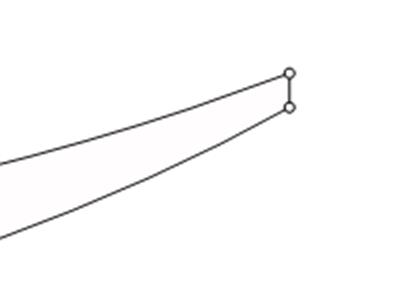

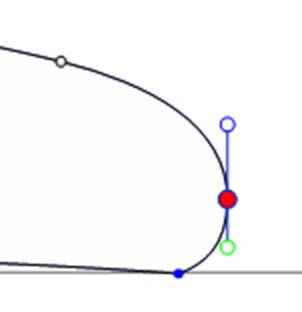

To modify the design of the curves, left click on the control points. The selected control point becomes red.

You can move the control points with the mouse, or with the arrows of the keyboard.

You can delete a control point pressing the button "Suppr" of the keyboard, or with a right click, selecting "Control point", "Delete".

You can also add a control point with a double left click at the position you want, or with a right click, selecting "Control point", "Add new point".

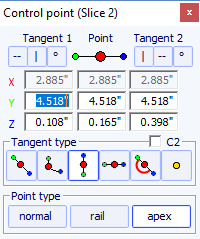

The properties of the selected control point are shown in the "Control point properties" box.

Five kind of tangents exist: continuous tangents ![]() , angular tangents

, angular tangents ![]() , vertical tangents

, vertical tangents ![]() , horizontal tangents

, horizontal tangents ![]() , and continuous tangents with

fixed angle

, and continuous tangents with

fixed angle ![]() .

.

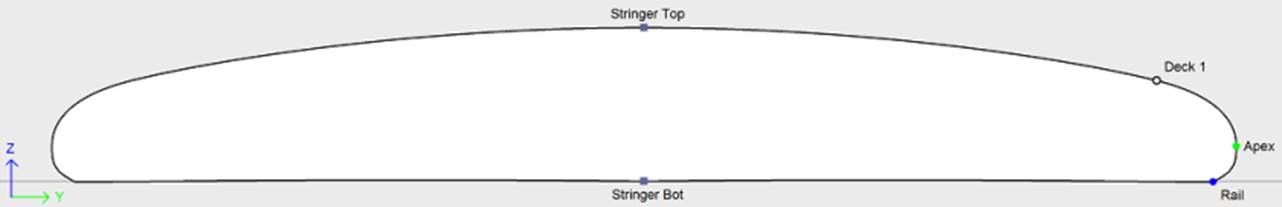

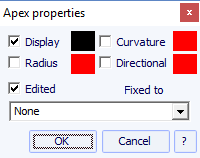

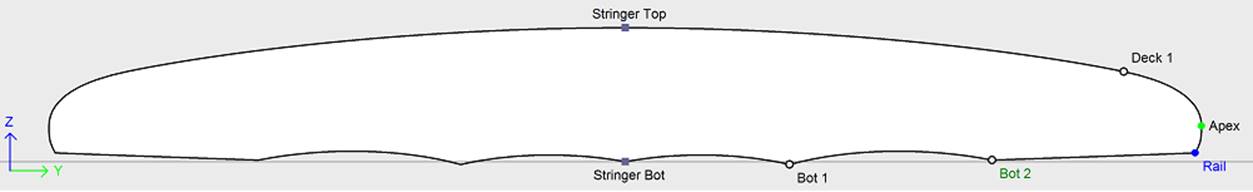

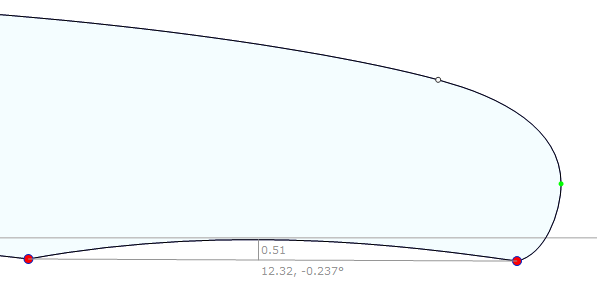

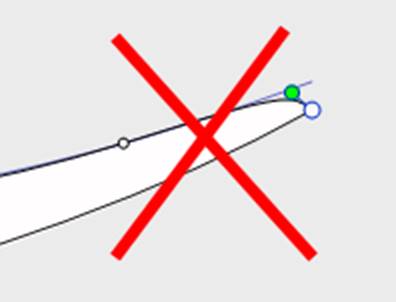

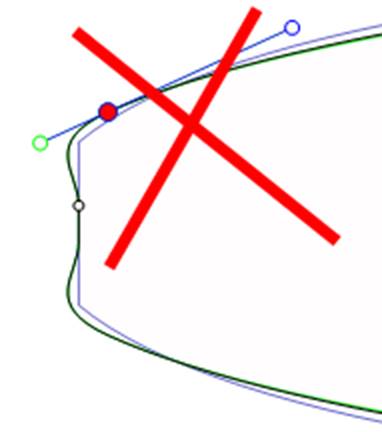

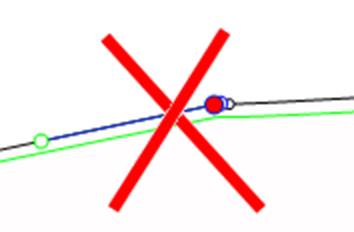

Continuous tangents are usually used. The angular tangents are more appropriate for the rail point of the slices, the vertical tangents for the apex of the slices, and the horizontal ones for the widest point of the outline, the zero point of the bottom, or the highest point of the thickness.

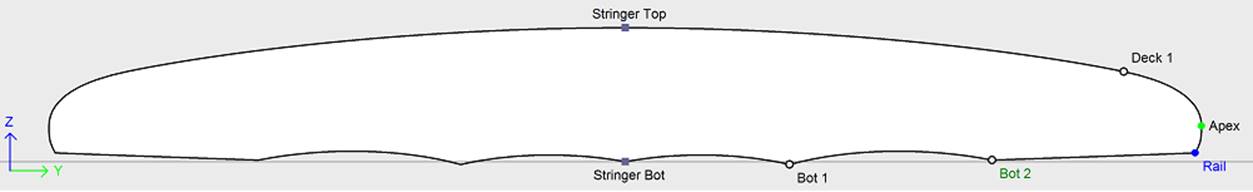

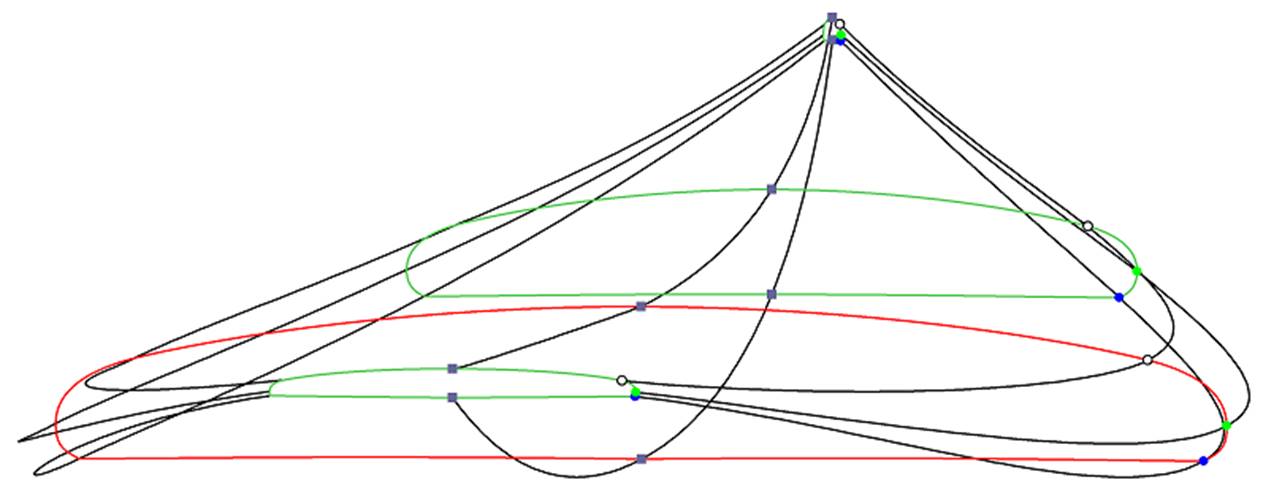

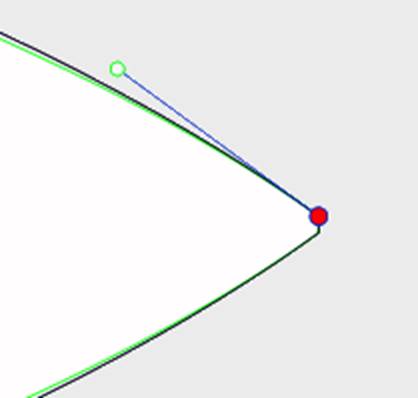

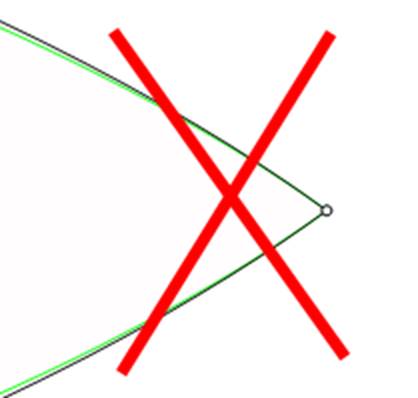

When designing the slices, it is recommended to set the point type

of the rail point as ![]() , and the apex point as

, and the apex point as ![]() . They will then appear in blue and green

respectively.

. They will then appear in blue and green

respectively.

All the slices must have the same number of control points.

The position of the slices can be modified with a right click, selecting "Slices", "Move slice". It can also be changed with the mouse in the outline view.

You can add or delete a slice, in the same way.

You can visualize the "flow" of the slices maintaining a left click in the outline, profile or thickness view. The width, rocker or thickness appear at the same time, as well as the distance from the tail and from the nose.

To understand the idea behind the design of a board with shape3d, just think about the rule of thumb: the less points the smoothest. Similarly, the less slices the smoothest.

Visualize the result of your art in the 3D View mode.

Note that all these actions can be done with the fre Lite version of Shape3dX.

As if you would design a board from scratch, go to the menu "File",

then "New", or press the button "New" ![]() , and fill in the name and size

areas.

, and fill in the name and size

areas.

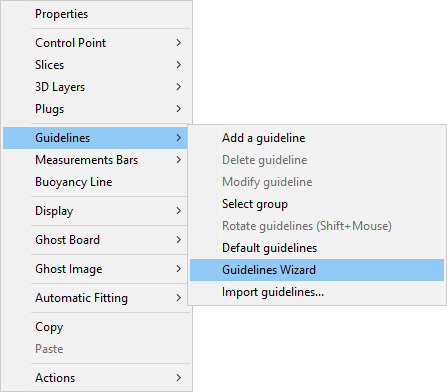

Then right click, select "Guidelines", "Guidelines Wizard":

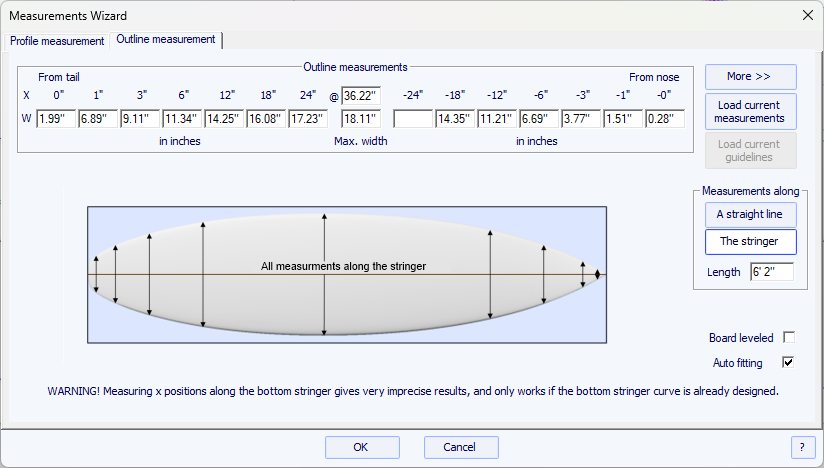

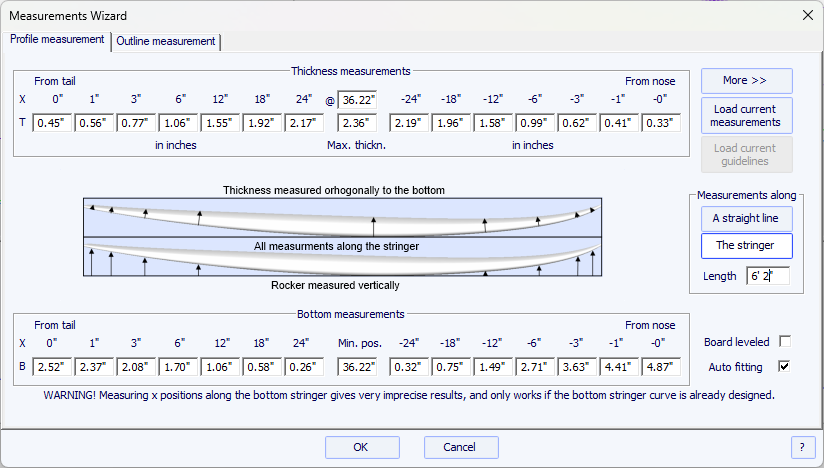

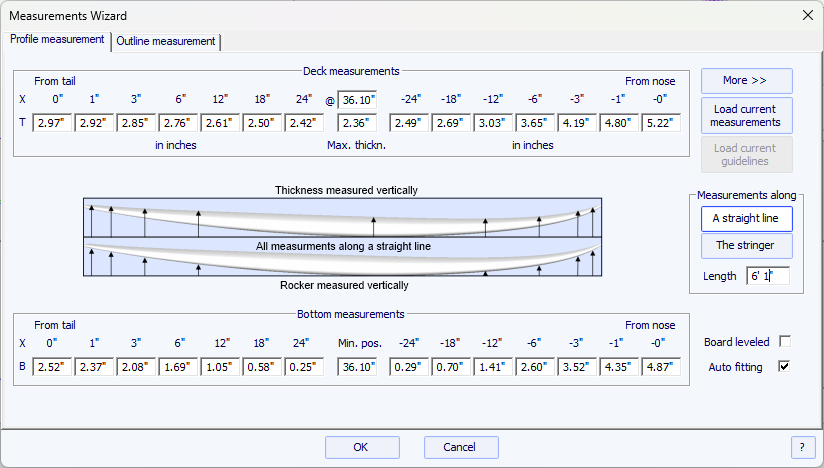

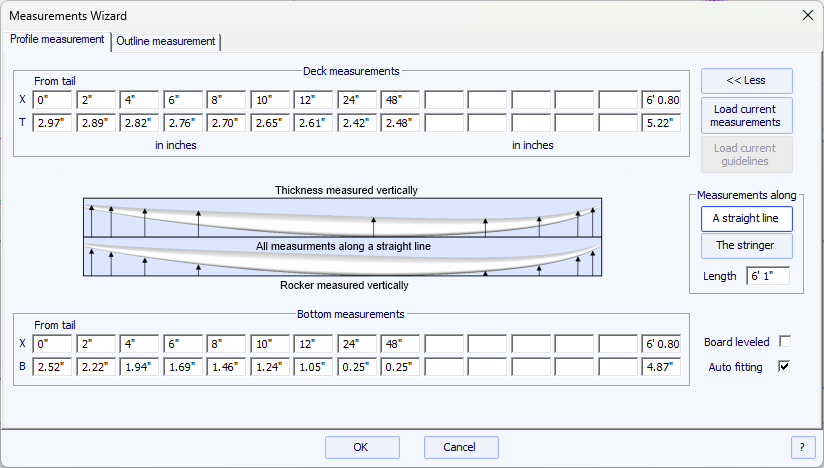

The Guidelines Wizard window pops up. It allows filling in the measurements of the outline and of the profile:

You can choose to measure the dimensions of the board along the bottom stringer:

or along a straight line, checking the box "Straight line measurements":

Note that measuring the board "Along the stringer" is always less precise than "Along a straight line", as the x positions will depend on the design of bottom stringer curve.

Click on the button more if you want to place the guidelines at other positions than the default ones:

The positions of the guidelines along the length direction depend on the chosen unit: in centimeters, the guidelines are located at 5, 10, 20, 30 cm... from the tail and the nose. In inches, the guidelines are located at 1", 3", 6", 12... from the tail and the nose.

You don't need to fill in each position box.

The outline and the profile will be automatically adjusted on the guidelines if you check the box "Automatic fitting". Note that the Automatic Fitting is not always good enough!

Press "OK" to see the board in the Design mode.

Note that the Guideline Wizard needs the Design option to be used, and the Automatic fitting needs the Pro option!

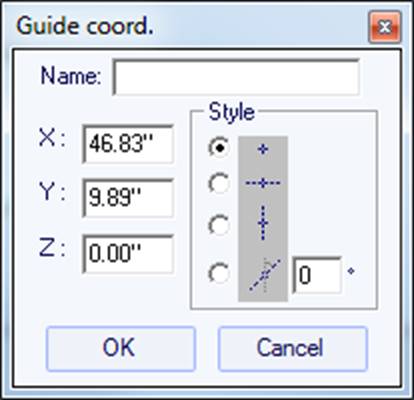

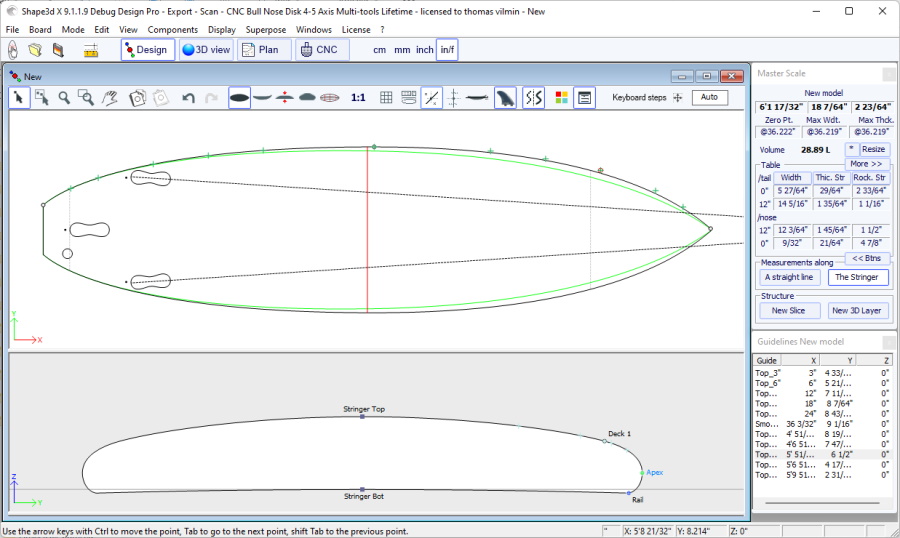

The guidelines appear as green crosses. Their list, with the positions, appears on the right hand side of the bottom of the screen.

You can change their position with the mouse, or the keyboard, or with a right click in the "Guidelines" box, which will make the following window appear.

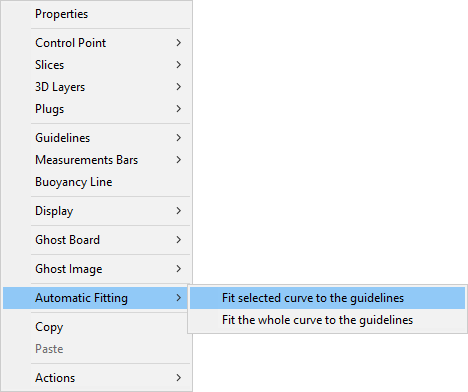

After changing the position of the guidelines, you can automatically fit the curves on the guidelines doing a right click on the selected curve.

If you click on a curve section between two control points, you have the possibility to adjust only this selected part of the curve, choosing "Fit selected curve to the guidelines".

Then you have to choose if you want to adjust the length or the direction of each tangent, or both. And press OK.

You can also choose to adjust the whole curve, clicking on "Fit the whole curve to the guidelines".

In this case you can choose the number of arcs (i.e. number of control points minus one) that will compose the whole curve. "Auto" will set it automatically, depending on the shape of the curve.

Once the design of the outline and profile is done, design the slices as explained in the chapter "Design a board from scratch".

Go to the menu "File", then "New", or press the button "New", and choose the tab "Blank design".

Set the rough measurements of the blank and press "OK". The blank will be automatically designed with square rails.

The smoothness of the curves is not guaranteed. You can modify the shape of the blank as shown in the chapter "Design a board from scratch".

Note that this can be done with the free Lite version of Shape3dx.

In the Design mode, the board is displayed projected in either the OXY, or OXZ or OYZ plan. The screen is splitted in up to 3 panels. The number of panels (1 to 3) can be changed in the menu Windows . The panels can be resized with the mouse.

The "Preferences..." window can be opened from the menu File.

It contains general settings that concern the Design mode, but also the Plan and CNC modes.

The "New" window can be opened through the button ![]() of the toolbar, or through the menu File.

of the toolbar, or through the menu File.

- Choose the model to start from between the examples proposed in the Warehouse. You can define a different default file for each Category/Type of design (Surfboard/Shortboard, Longboard, Windsurf...).

- Enter the name of the model you are going to design, and your name as a shaper. Add any comments you want.

- Choose the dimensions unit: centimeters, millimeters, inches or fractional inches.

- Check "Constrain proportions" if you want to keep the same ratio Length/Width/Thickness/Rocker... as the starting model.

- Check the box "Stringer measurement" if these dimensions are measured along the stringer. Uncheck it if they are measured along a straight line.

- Check the box "Symmetric nose/tail" for a twin-tip board.

- Check the box "Symmetric right/left" for a regular board. Uncheck this option for an asymmetrical board.

- Input length, width, thickness, and tail/nose rocker.

- You can set the thickness of the sandwich if the board is designed to be built with the sandwich technology.

- Press OK.

The starting model appears in the Design mode.

Set the rough measurements of the blank and press "OK". The blank will be automatically designed with square rails.

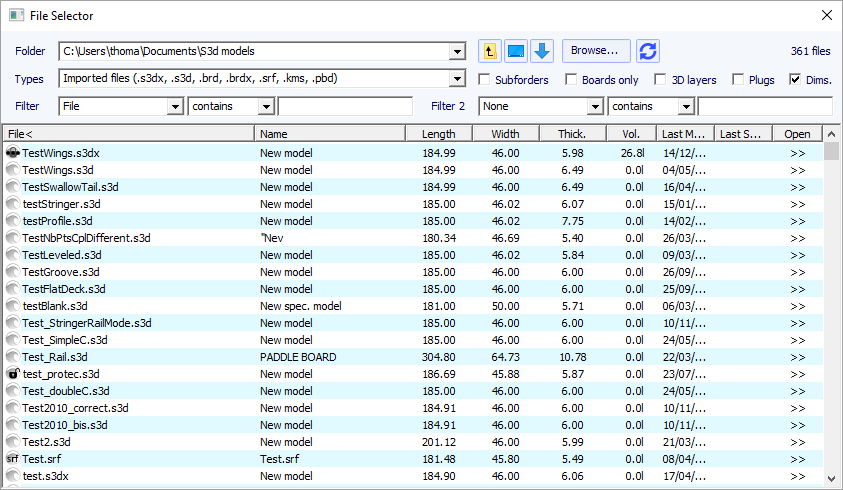

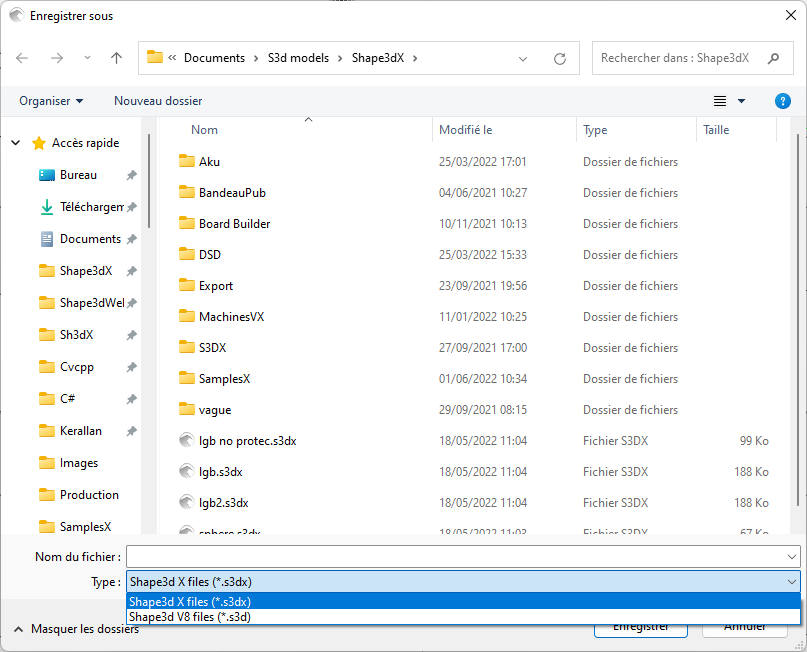

The "File Selector" window can be opened through the menu File, or from the button Open

![]() of the toolbar.

Note that the first time you'll click on the Open button you'll be asked if you want to use the File Selector or the Windows file browser to open files.

This choice can be modified later on in the Preferences (menu File).

of the toolbar.

Note that the first time you'll click on the Open button you'll be asked if you want to use the File Selector or the Windows file browser to open files.

This choice can be modified later on in the Preferences (menu File).

The File Selector shows the list of files of a selected folder, just like the the Windows file browser. It also provides a preview of the Shape3d files the same way:

But in addition it gives you the dimensions of all loaded files, and allows you sorting and filtering the files by name, length, width...

and also category, type, rider profile...

It also has a contextual menu that allows Renaming, Deleting or Moving one or several files.

You can also Protect or Unprotect the selected files or all the files of the folder.

And you can do a CSV export of the dimensions and properties of the selected files.

Note that you need a Design Pro license to protect a list of files, and export the dimensions in the CSV format.

The "Size and parameters" window can be opened through the button ![]() of toolbar, or through the menu Board->Properties.

of toolbar, or through the menu Board->Properties.

In the "Dimensions" tab you can change the measurements "Unit", and the "Precision" of the displayed measurements:

from 0.1 to 0.00001 (1 to 1/64" for fractional inches).

You can also change the symmetry properties of your design: "Symmetric nose/tail" and "Symmetric right/left".

And you can choose to display the length measurements "Along the stringer"

(which means that we measure the developped length along the bottom stringer curve of the board)

instead of Along a straight horizontal line. Note that the lengths are larger if measured "Along the stringer" mode!

The "Dimensions" tab allows Resizing your design. There are several resizing modes:

- The "Constant proportions" mode will modify the width, thickness and rocker proportionaly to the length.

- The "Constant side proportions" mode will only modify the thickness and rocker proportionaly to the length.

- And the "Constant rocker proportions" mode will only modify the rocker proportionaly to the length.

Note that in the "Constant rocker prop." mode you can choose to resize the V/Concave proportionaly to the thickness, or to the rocker,

or keep it constant while resizing the board (None, which was the default value before version 9.1.1.1).

These resizing modes can be parameterized with custom proportion coefficients between rocker and length variations (Dr/Dl), width and length variations (Dw/Dl),

and thickness and length variations (Dt/Dl).

The "Dimensions" tab also gives the possibility the increase or lower the "Rail thickness"

(change the rail thickness the 50% to make the rails half thinner, change it to 200% to make it twice thicker).

The "Sandwich" field can be used to remove a constant thickness on the whole board for sandwich construction.

The sandwich thickness removed on the slices is displayed in the Design mode, and it will be taken into account for the cut in the CNC mode

(the sandwich thickness can be changed in the CNC mode).

On the other hand, it is not taken into account for the 3D exports in the STL, DXF or IGES formats!

Note that the resizing can be done with the free Lite version of Shape3dx.

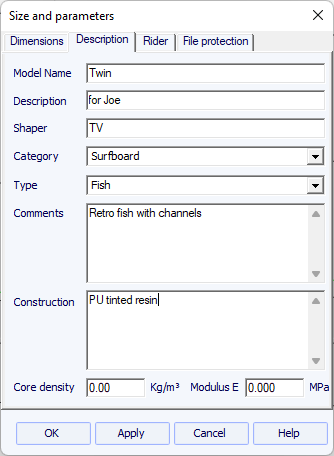

The "Description" allows you naming the design and adding descriptions.

You can select the Category and the Type of the design, which can be used to sort your files in the File Selector later on.

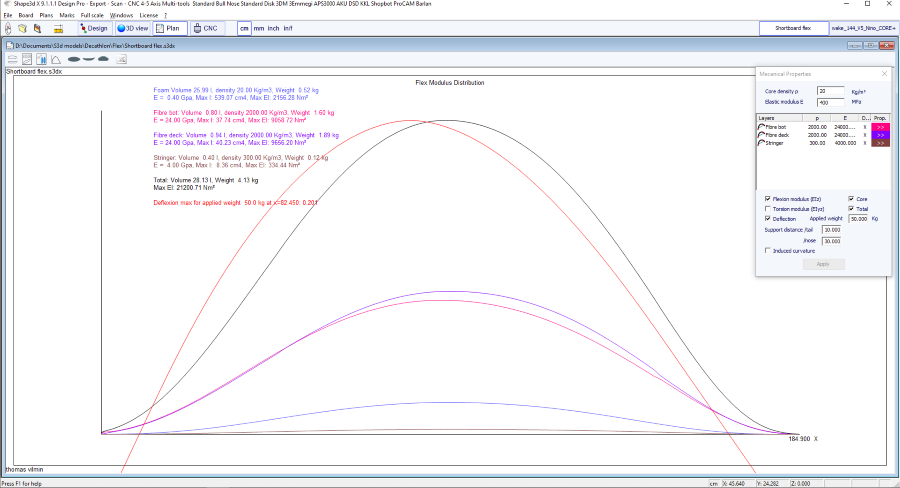

You can also define the density of the core, which will allow computing the final weight of the board.

And the Elastic Modulus, which will allow computing the stiffness of the board.

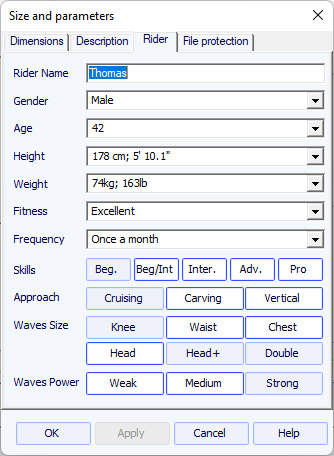

The "Rider" tab allows you registering the profile of the user of your design. These informations as well can be used to sort your files in the File Selector later on.

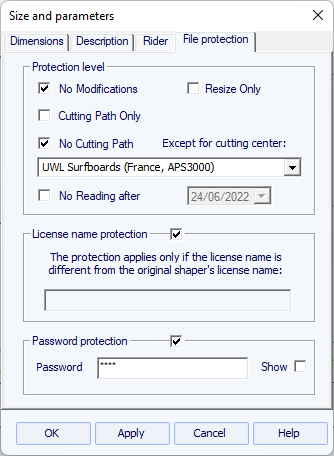

The files produced by Shape3d can be encrypted, to prevent other Shape3d users from reading, copying and/or cutting your boards.

The protection system can either use your License Name (the file is protected against anyone whose license name differs from yours) and/or a Password (other users will need your password to unlock the protection).

- Checking the box "No Modifications" prevents from the modification and copy of your model.

- If the box "Resize Only" is checked, then the model can only be resized from the Size and parameters window. The outline, profile and slices can't be modified by someone else than the file owner.

- Check the box "Cutting Path Only" to hide the board dimensions and cross sections. That's an additional protection to prevent any copy using the measurements given by Shape3d.

- Checking the box "No Cutting Path" blocks the export of cutting path. This level of protection can be set for all cutting centers except one. Select the cutting center in the drop down list then.

- Checking the box "No Reading after" will make the file impossible to open after the chosen date.

Note that the file protection needs the Design option to be used. Protected files can't be open with the Lite version of Shape3dX.

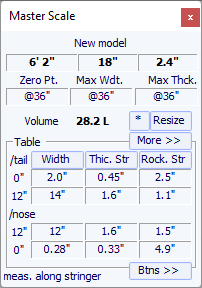

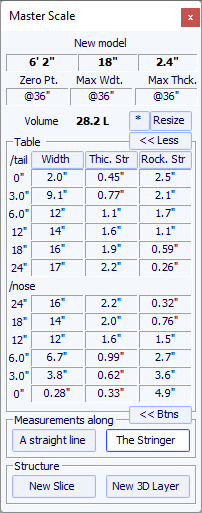

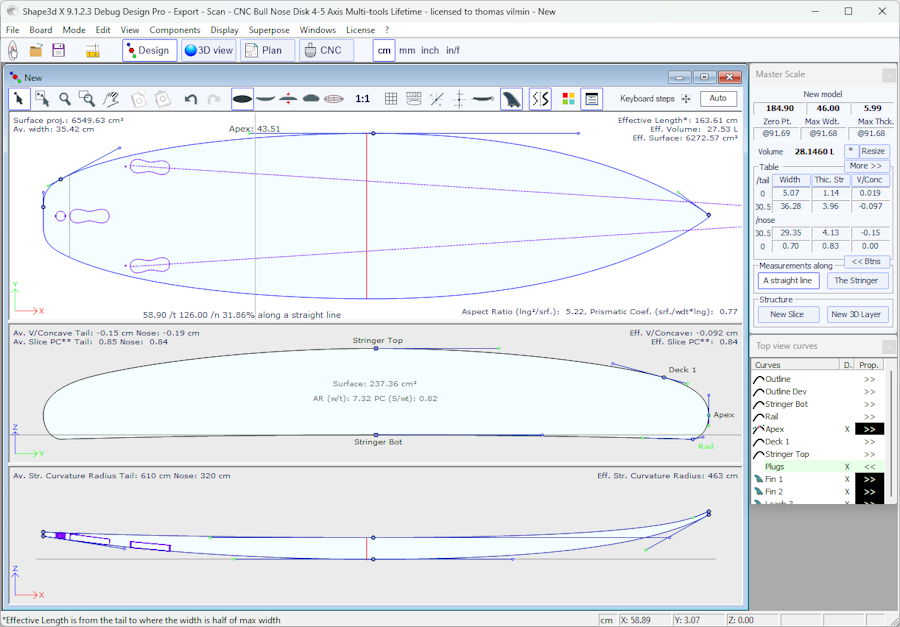

The "Master Scale" window provides the general information on the board:

The name, and the volume, length, width, thickness of the model. It also gives the tail and nose rocker, the position of the zero point, and the measurements at 0 and 12" (or 0 and 30 cm) from the tail and the nose.

Press "Resize" to change the general dimensions of the board.

The "*" button opens the Volume Wizard window that allows adjusting a dimension to get the desired volume.

One can also visualize more measurements, clicking on "More >>".

Note that measurement columns can be organized the way you want. And you can choose the display either the Width, the Stringer Rocker (center point of the bottom), the Profile Rocker (lowest point of the bottom), the Stringer Thickness (thickness at the center of the board), the Profile Thickness (thickness between lowest and highest points), or the depth of the V or Concave of the bottom of the board.

You can choose to edit the dimensions taken along a straight line or along the stringer line, pressing the button "A Straight Line " or "The Stringer".

- Measurements along a straight line give width and height measurements that are taken at a defined distance straight from the tail.

- Measurements along the stringer give width and height measurements taken at a defined distance along the curve of the bottom stringer from the tail.

Note that 12" from the tail along a straight line is farther from the tail than 12" from the tail along the stringer, so it will give a larger width and smaller rocker. And 12" from the nose along a straight line is farther from the nose than 12" from the nose along the stringer.

You can also add a slice or a 3D layer.

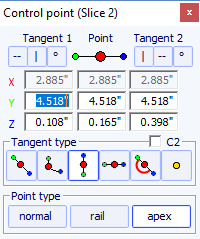

The properties of a selected control point are shown in the " Control point properties " box.

The position of the control point and its tangents can be changed manually. The modifications you enter will be taken into account if you change the cell or click Enter.

Five kind of tangents exist: continuous tangents ![]() , angular tangents

, angular tangents ![]() , vertical tangents

, vertical tangents ![]() , horizontal tangents

, horizontal tangents ![]() , continuous tangents with

fixed angle

, continuous tangents with

fixed angle ![]() , and passive point with no

tangents

, and passive point with no

tangents ![]() .

.

The "C2" option forces the curvature continuity on both sides of the tangent.

Continuous tangents are usually used. The angular tangents are more appropriate for the rail point of the slices, the vertical tangents for the apex of the slices, and the horizontal ones for the widest point of the outline, the zero point of the bottom, or the highest point of the thickness.

When designing the slices, it is recommended to set the point type

of the rail point as ![]() , and the apex point as

, and the apex point as ![]() . They will then appear in blue and green

respectively.

. They will then appear in blue and green

respectively.

All the slices of a board must have the same number of control

points. This can be annoying some time if it forces you to add

un-useful control points to a slice. In this case you can set the

point as passive ![]() . Then the control point will

be like a dead point and you won't have to set its tangents... The

passives points appear in yellow, and they have no tangents.

. Then the control point will

be like a dead point and you won't have to set its tangents... The

passives points appear in yellow, and they have no tangents.

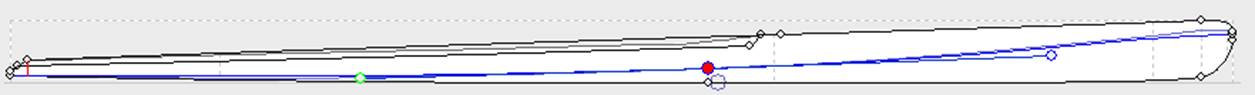

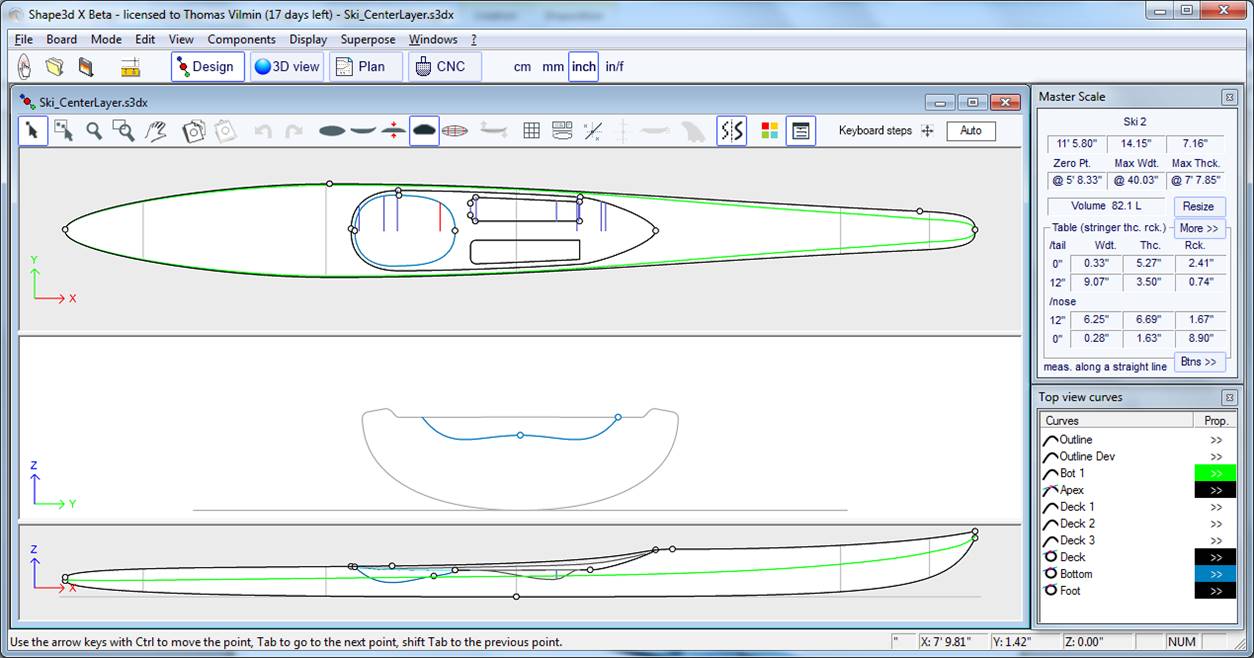

As we said earlier, all the slices of a board have the same number of control points. And the curves joining these points define the whole shape of the board.

The control points of the slices are named automatically.

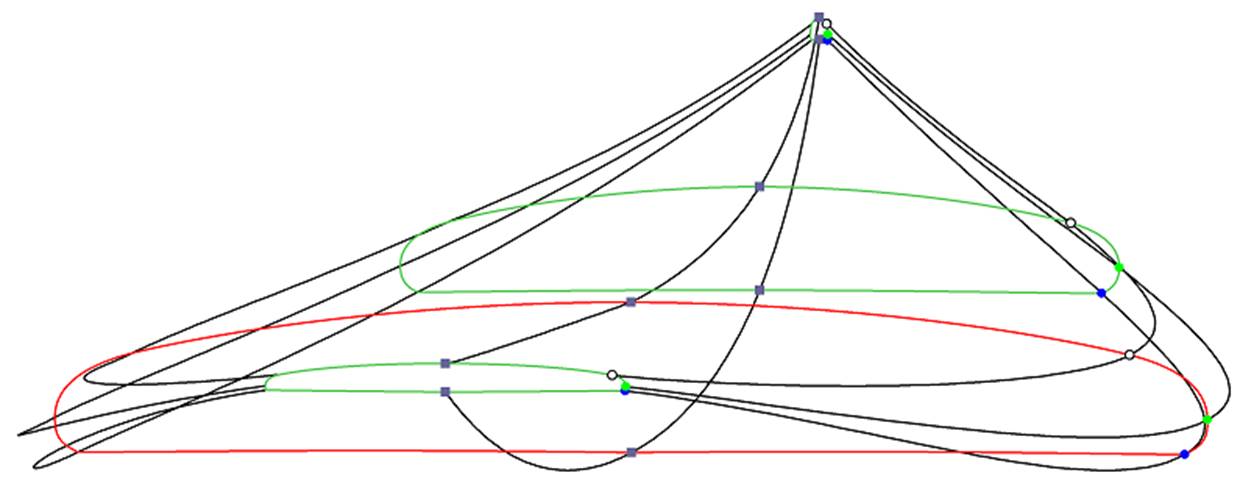

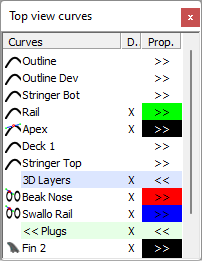

The curves that correspond to each of these points can be displayed both on the Top view panel and the Side view panel. When one of these panels is selected the list of the curves appears on the side:

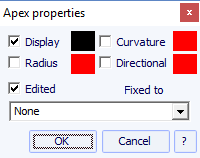

To display the properties of a curve, click on >> or double-click on its line.

The name of each curve can be modified. You can also select another curve from the drop-down list.

Each curve can be displayed or not in a different color. The

Curvature, Curvature Radius, and Directional Curvature Radius (same

as SurfCAD) can also be displayed in other colors.

If the option "Display curvature along the curve" is selected in the Preferences window (see menu File),

the curvature curves are displayed perpendicularly to the original curves.

In comparison, if this option is not selected, the curvatures are drawn along the X axis.

One of the most important new feature of Shape3d X is that each

curve (except the Developed Outline and the True Apex) can be Edited

or not in the Top and/or the Side view. If a curve is Edited ![]() , it means that the user can modify the curves moving

the control points and tangents. If a curve is Not Edited

, it means that the user can modify the curves moving

the control points and tangents. If a curve is Not Edited ![]() , it means that the curve is computed by Shape3d.

, it means that the curve is computed by Shape3d.

Note that you can edit or un-edit a curve if you right-click on it in the curves list.

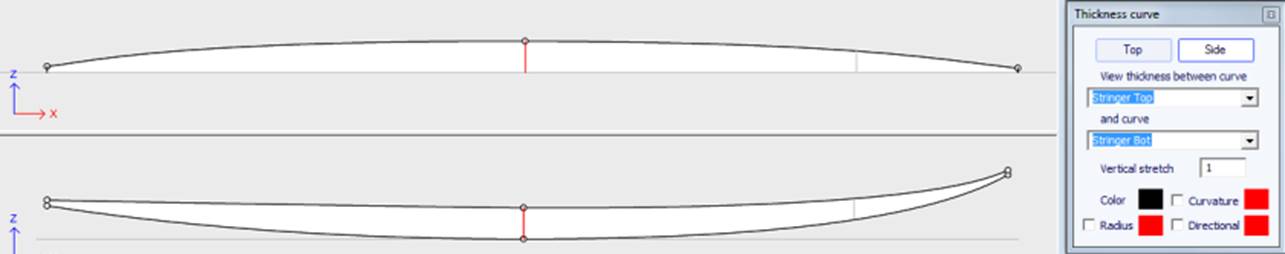

The Edited curves can be set Fixed to another edited curve ![]() . This means that the relative distance between the

two curves will stay constant when the second curve is modified. For

example one can set the Deck Stringer line Fixed to the Bottom

Stringer line, so that the stringer thickness doesn't change when

the Bottom Stringer line is modified. This thickness can be

displayed in the Thickness View.

. This means that the relative distance between the

two curves will stay constant when the second curve is modified. For

example one can set the Deck Stringer line Fixed to the Bottom

Stringer line, so that the stringer thickness doesn't change when

the Bottom Stringer line is modified. This thickness can be

displayed in the Thickness View.

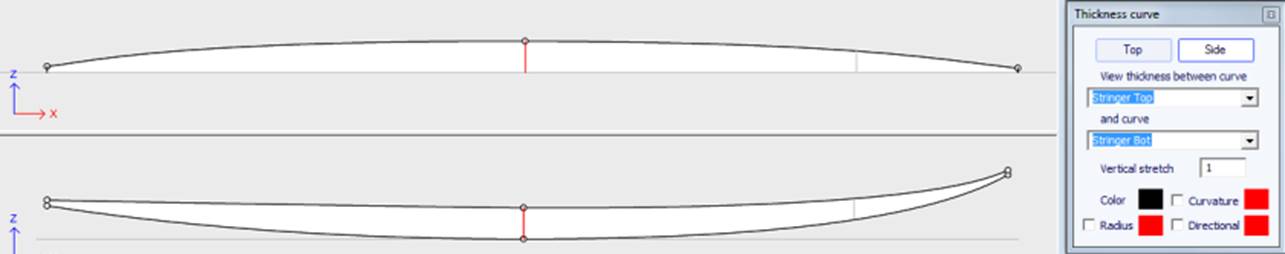

In the Thickness View, if the curve displayed corresponds to the thickness between a curve that is fixed to another one and this other curve, the control points appear and the curve can be modified. In this view the curvatures can be displayed, and the colors changed. Also the curve can be stretched vertically if it's too flat to be seen correctly.

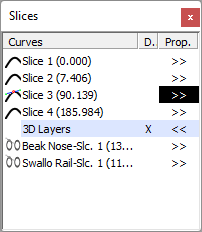

When the Slices view is active, the list of curves is replaced by the list of slices.

The slices are listed with their positions, which allows avoiding getting two slices at the same place.

Click on a line to edit the corresponding slice on the slices view. You can click in the Diplay (D.) column to display multiple slices. The diplayed slices (in addition to the edited slice) have a X in the D. column.

If you double click on a line, or click on >>, the slices properties window pops up.

In this window you can change the slice position.

You can change its color and diplay or hide it.

You can also display the curvature, the curvature radius and the

directional curvature radius of the slice. And you can delete the

slice.

You can also select another slicte in the drop-down list.

Since version 9.1.0.4 the slices can be defined on the Deck only or Bottom only. This feature allows modifying the bottom or deck of the board without risking to decrease the smoothness of the board on the other side.

You can also save the slice in a separated s3dx file. And you can load the slice from an s3dx file that contains a slice or from a board file.

One of the most important new feature of Shape3d X is that each

curve (except the Developed Outline and the True Apex) can be Edited

or not in the Top and/or the Side view. If a curve is Edited ![]() , it means that the user can modify the curves moving

the control points and tangents. If a curve is Not Edited

, it means that the user can modify the curves moving

the control points and tangents. If a curve is Not Edited ![]() , it means that the curve is computed by Shape3d.

, it means that the curve is computed by Shape3d.

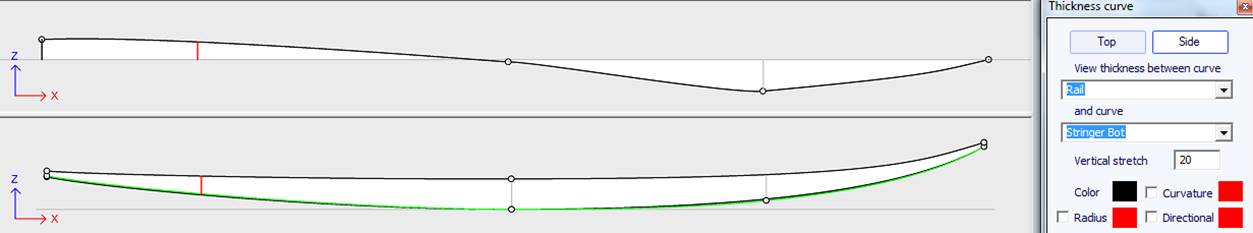

For example, in the Side view, one can choose to edit the Bottom and Deck Stringer curves, but also the Rail line at the same time (this is the case when you open a .srf file). It gives a complete control of both stringer and rail and let the other curves be computed by Shape3d. In this case the Rail points of the slices will be locked in the vertical Z direction.

Edited curves can be saved as a separate s3dx file. And you can load a curve from an s3dx file containing a curve or from a board file.

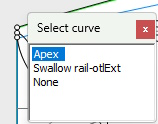

When several curves are edited, if you click between two control points a window will pop-up to let you choose the curve.

Here are all the design possibilities you have for the Top View and the Side View curves:

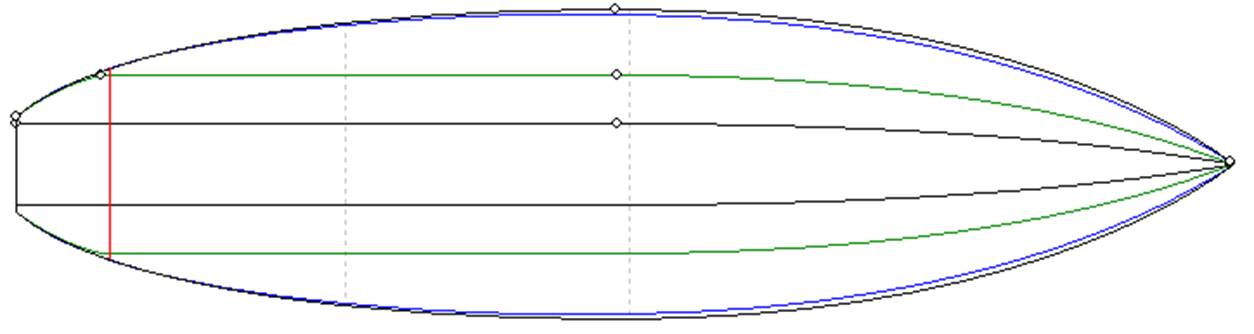

- In the Top View the most common design method is the work on the Apex curve (the curve corresponding to the control point defined as the Apex on the slices).

Then you can choose to also edit the Rail curve if you want more control on the Rail curve. You can also edit several of the bottom curves on the Top View to control the shape of the channels of a board for example:

- If the slices don't have an Apex point defined, you can choose to work on the Outline curve. But then you won't be allowed to edit other curves like the Rail curve for example.

- In the Side View the most common design method is the work on the Bottom and Deck Stringer curves, which correspond to the first and last control points of the slices.

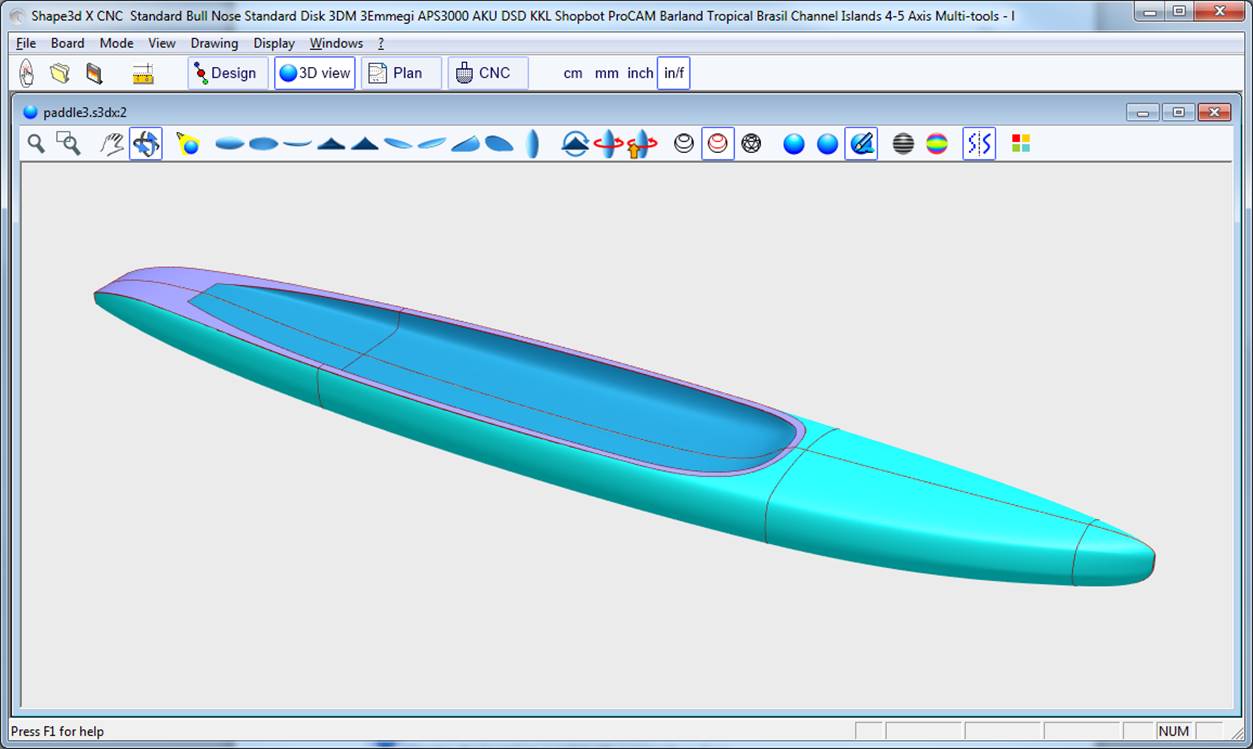

Then you can choose to also edit the Rail curve if you want more control on the Rail curve. You can also edit the Apex curve in the Side View, which can be very useful on some shapes like paddle boards:

- Another way of designing the side view is the work on the Bottom and Deck Profiles curves , which correspond to the shadow of the board. But then you won't be allowed to edit other curves like the Rail curve for example.

The Edited curves can be set Fixed to another edited curve ![]() . This means that the relative distance between the

two curves will stay constant when the second curve is modified. For

example one can set the Deck Stringer line Fixed to the Bottom

Stringer line, so that the stringer thickness doesn't change when

the Bottom Stringer line is modified. This thickness can be

displayed in the Thickness View.

. This means that the relative distance between the

two curves will stay constant when the second curve is modified. For

example one can set the Deck Stringer line Fixed to the Bottom

Stringer line, so that the stringer thickness doesn't change when

the Bottom Stringer line is modified. This thickness can be

displayed in the Thickness View.

If rail and stringer are both edited, you can choose to lock the rail line to the stringer line so that the depth of the concave or V doesn't change when you modify the stringer line. Then you can display the depth of the concave or V in the thickness panel and stretch it vertically to have a better view of the details...

In the Thickness View, if the curve displayed corresponds to the thickness between a curve that is fixed to another one and this other curve, the control points appear and the curve can be modified. In this view the curvatures can be displayed, and the colors changed. Also the curve can be stretched vertically if it's too flat to be seen correctly.

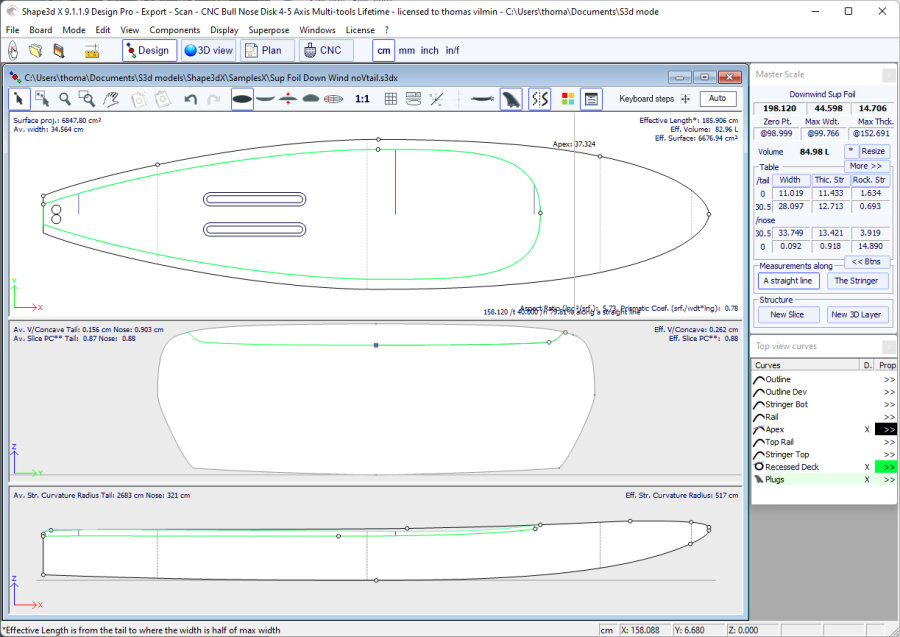

- With version 9.1.0.0 and higher, you can now edit the stringer curve in the top view:

Bending the stringer curve (bottom or deck or both) in the Top view allows designing a Bevel nose,

because you can designe the slices past the center axis, and the final rendering will cut these slices along the center axis.

It also allows designing swallow tail:

You can download these sample files in the Warehouse.

Note that the Multi-curves Edition needs the Pro option to be used.

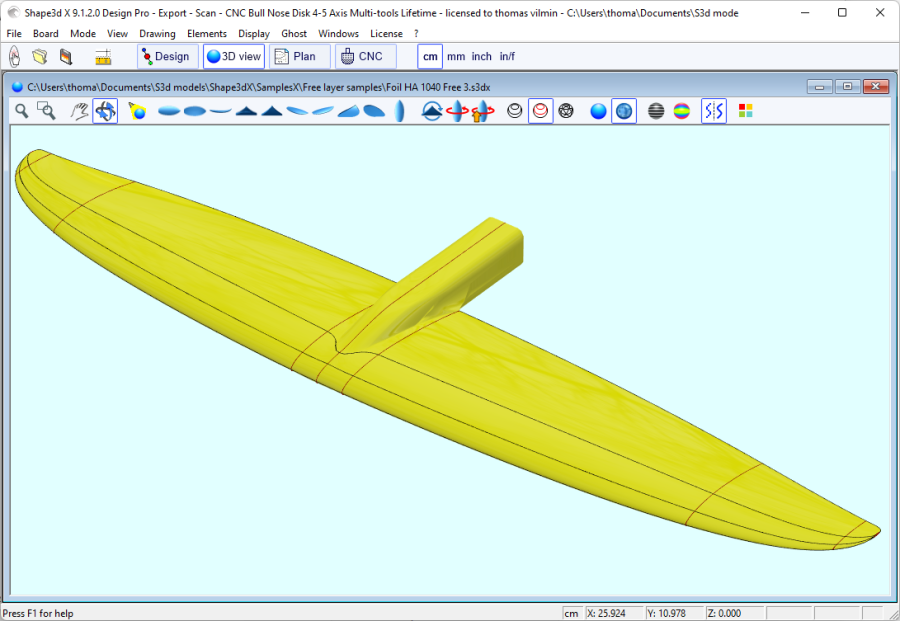

Version 9.1.0.0 and higher allows designing asymmetric boards. This also means you can design fins or foils! To release the symmetry constraint, just uncheck the "Symmetric right/left" option in the "Size and Parameters" window. The right hand side curves will then become editable in the Top and Side views, and also in the Slices view. The curves of both sides appear in the curves list window:

As the stringer curves of the Right hand side (bottom and/or deck) can be edited in the Top view, fins or foils can be easily designed:

Note that editing the top view stringer curves on the Right hand side allows designing bent stringer on asymmetric boards, editing the top view stringer curves on the Left hand side allows designing bevel nose or swallow tails!

You can download these sample files in the Warehouse.

Note that Asymmetric models can only be designed using the Pro option.

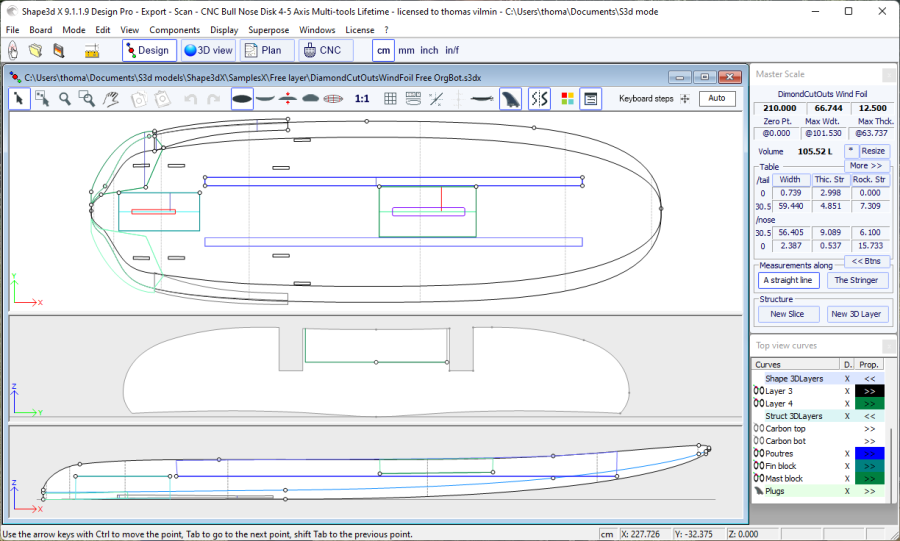

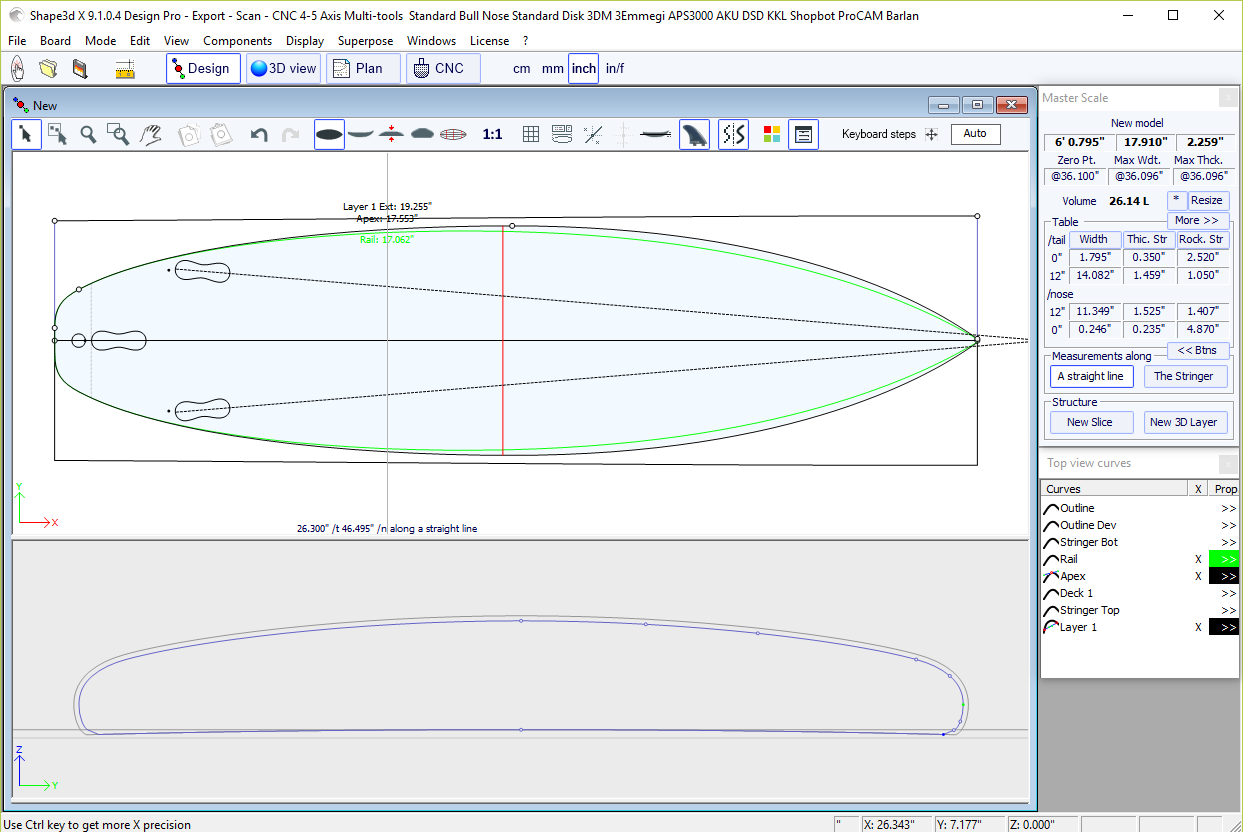

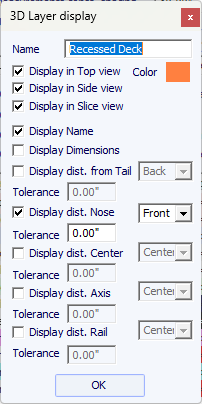

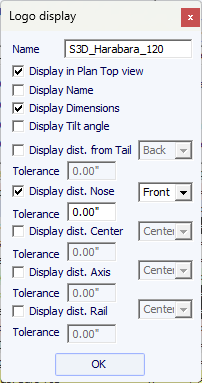

The second most important new feature of Shape3d X is the possibility to add or subtract shapes to a board. These shapes are called 3D Layers. To add a 3D layer, simply click on the button New 3D Layer in the Master Scale window.

The 3D layers can be added to the deck or the bottom of the board. Its curves and curvatures can be displayed in any color. If the Active box is not checked, its shape won't be added in the 3D view or in the CNC mode. Once created, the 3D layer appears at the end of the curves list. The name can be changed.

On asymmetrical boards, the 3D layers can be positionned only on one side (left or right), or on both.

For nose/tail symmetrical boards, the 3D layers can be defined as "Centered X", which means that the center of the layer is at the center of the board. Or it can be set as "Symmetrical nose/tail", which means that it must be placed on the back half of the board, and will automatically be duplicated on the nose of the board symmetricaly.

There are 6 kinds of 3D layer:

- The Center layers ![]() are shapes which outline is designed in the Top View,

and the depth ( side curve) is defined in the side view.

are shapes which outline is designed in the Top View,

and the depth ( side curve) is defined in the side view.

It contains slices that are mapped on the board slices.

The width Y of the slices is set by the outline curve of the layer, and height Z of the center point is set by the side curve of the layer.

The last control point of the slices is stuck to the original board slice.

The number of slices is not limited.

In the resulting shape the volume between the original board slices and the 3D layer slices

is removed if the layer slices are inside the board slices, or added if they are outside.

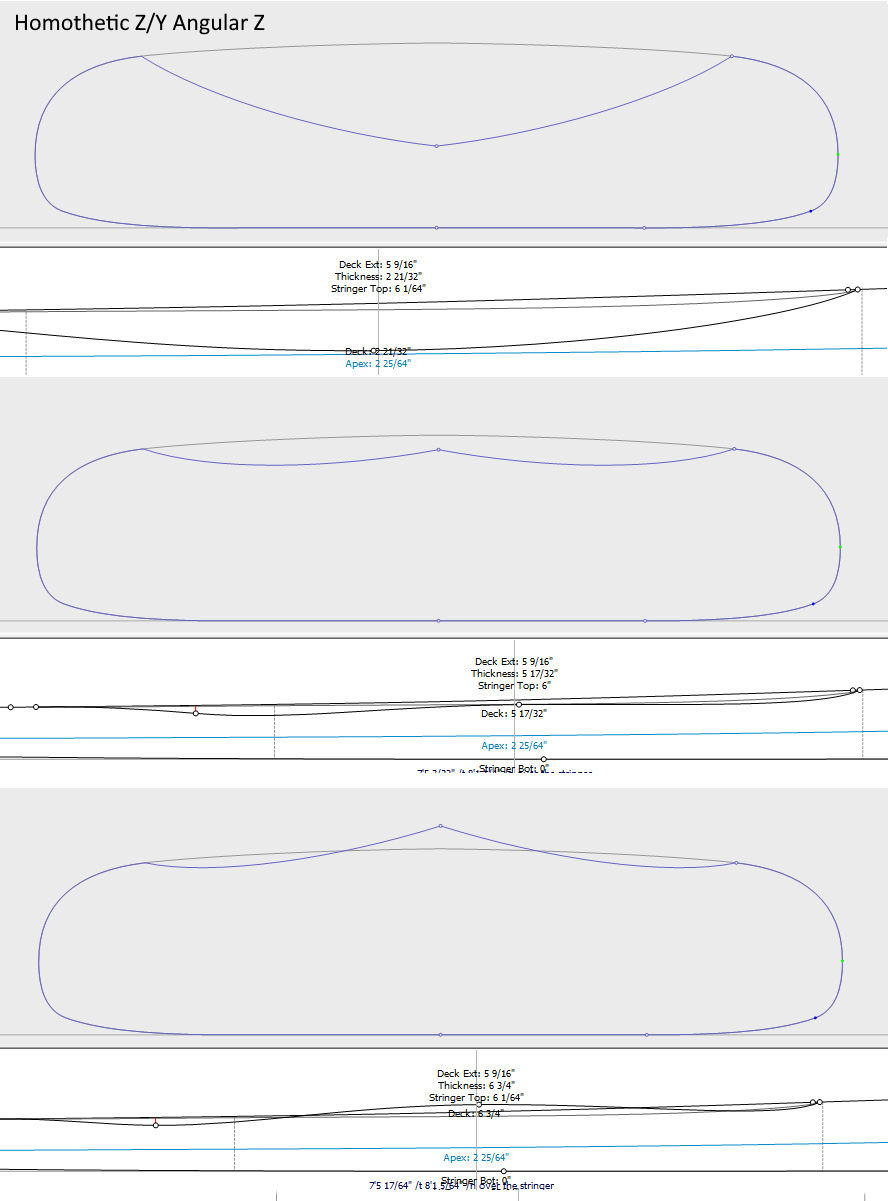

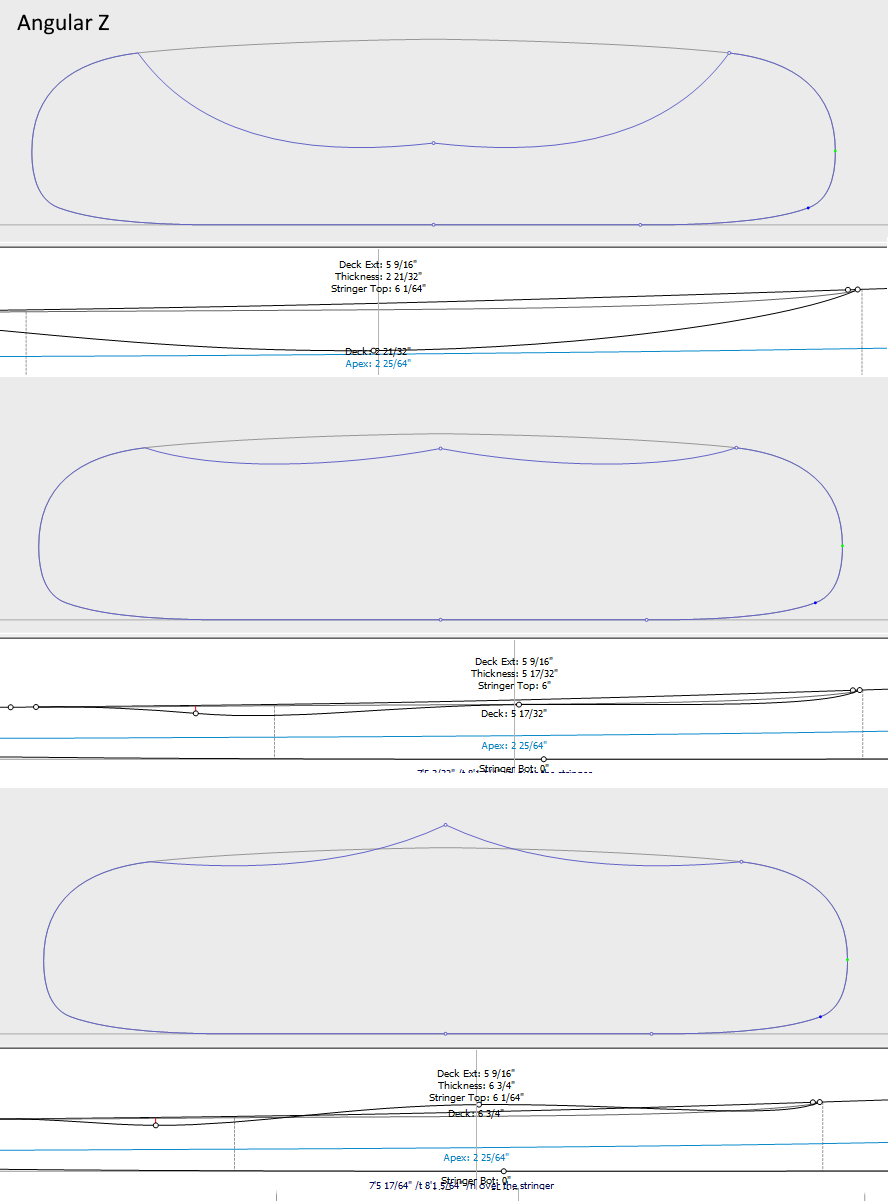

There are 3 interpolation modes: In the Homothetic Z/YZ mode, the height of the slices is rescaled homothetically with the width and with the ends Z variation. In the Angular Z mode the height of the slices doesn't depend on their width, it's adjusted with the angle of its ends. The Homothetic Z/Y Angular Z mode is a mix of the two other modes: the height of the slices is rescaled homothetically with the width, and then adjusted with the angle of its ends.

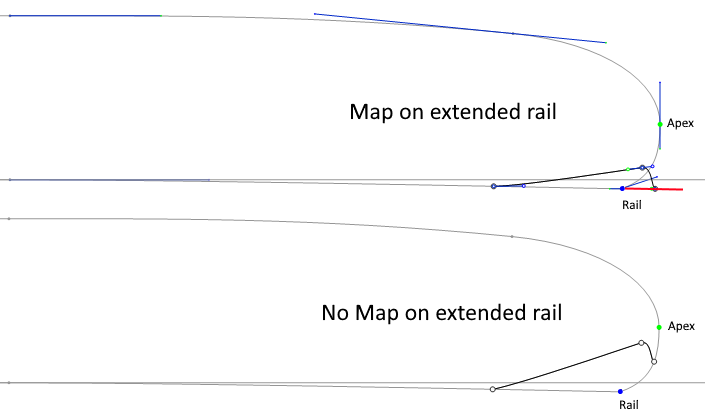

The option "Map on extended rail" allows mapping the layer's slices on a straight line extrapolated from the rail point. Note that since version 9.1.2.0 you can define a rail point on the bottom of the slices, but also on the deck.

The outer side of the layer can be mapped on the opposite side (i.e. Bottom for a Deck layer, or Deck for a Bottom 3D layer). For a deck 3D layer for example, the outer point of the layer's slices will be stuck on the bottom part of the board's original slices instead of the deck.

The option "Smooth edge" forces the tangents at the edge of the layer's slices to be parallel to the board's original slices.

The addition of new slices is done through the menu Slices -> Add new slice on selected 3D layer.

For smooth transition of the 3D layer's slice with the board's slice, the control point's tangents can be aligned with the board's slice curve with the menu Control Point -> Stick selected point to original shape.

The whole slice of the 3D layer can be stuck to the board's slice with the menu Slices -> Stick selected slice to original shape.

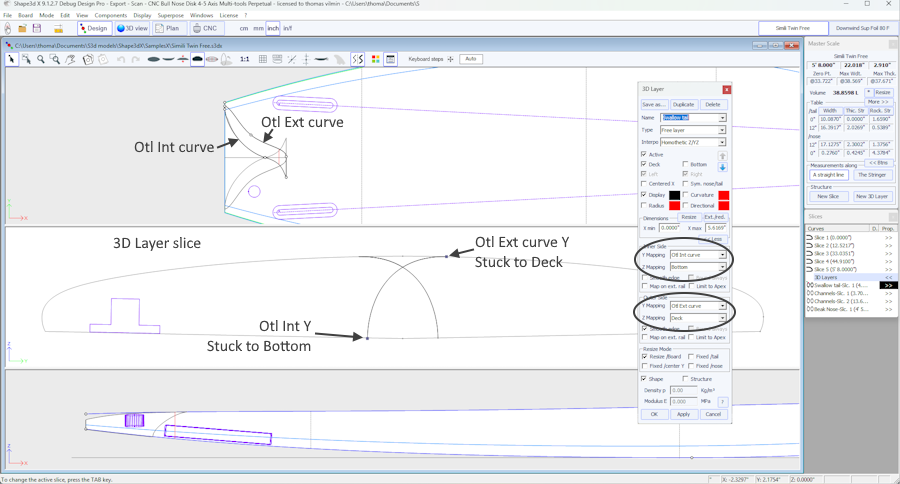

- The Twin layers ![]() is similar to a Center layer but it has an Outer outline curve Otl Ext

and an Inner outline curve Otl Int in the Top view.

is similar to a Center layer but it has an Outer outline curve Otl Ext

and an Inner outline curve Otl Int in the Top view.

There is no Side curve defining depth of the layer!

The depth is set by the slices that are mapped on the board slices.

The Y position of the first control point of the slices (the closest to the center) is set by the Otl Int curve,

and it is verticaly suck to the slice of the board.

The Y position of the last control point of the slices (the closest to the rail) is set by the Otl Ext curve,

and it is verticaly suck to the slice of the board.

The number of slices is not limited.

In the resulting shape the volume between the original board slices and the 3D layer slices

is removed if the layer slices are inside the board slices, or added if they are outside.

The options and the interpolation method, and the design of the slices, are the same as for Center layers.

Note that we more likely use the Angular Z interpolation mode for Twin layers

as the Homothetic Z/YZ mode gives bad results if the height difference between the inner and outer side changes sign.

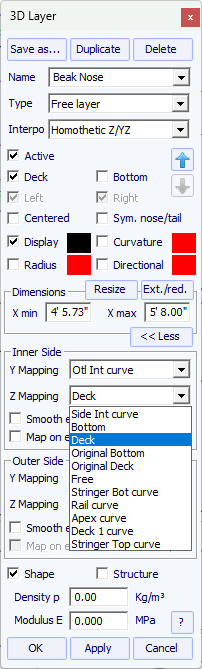

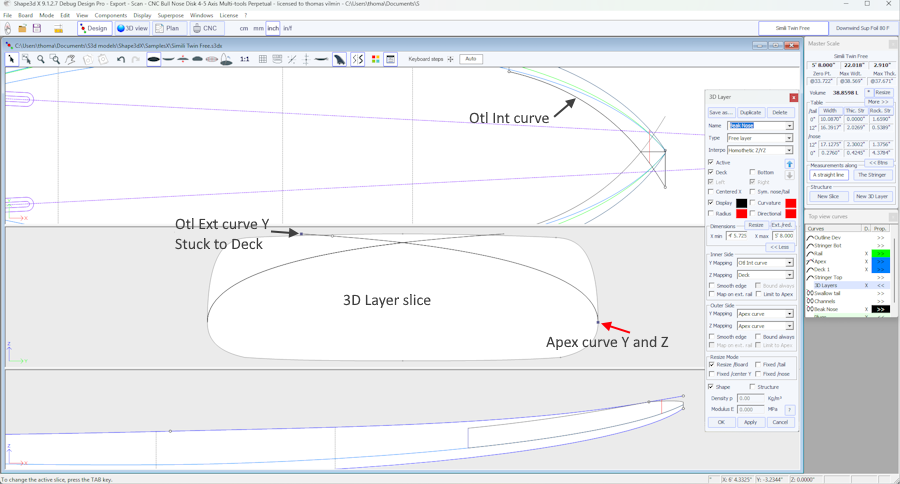

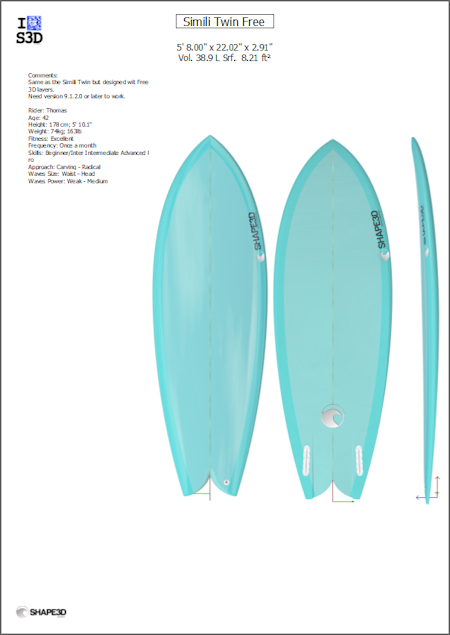

- Since version 9.1.2.0 a new 3D layers type has been added: the Free layers ![]() .

It is a combination of the Center layers and Twin layers with much more freedom and possibilities.

.

It is a combination of the Center layers and Twin layers with much more freedom and possibilities.

For the Inner and the Outer sides Top view definition (Y Mapping) you have the choice to use an Otl curve,

or any of the Definition curves of the original shape

(i.e. Apex curve, Rail curve...).

You can also set the Inner or the Outer sides to the Center,

or the Rail, or even let it Free.

For the Side view definition (Z Mapping) of the Inner and the Outer sides,

you also have the choice to use an Side curve,

or any of the Definition curves of the original shape.

And you can also choose to stick Inner or the Outer sides to the Bottom or Deck,

or the Original Bottom or Original Deck (i.e. the Bottom

or Deck before other 3D layers have been added).

You can also let it Free.

This allows you to have the maximum of control in the design of the 3D layer, and give new possibilities.

If you use an Otl curve for the Y Mapping, you can make the curve go past the center axis.

In this case the final shape will have the layer cut on the center axis.

This allows designing Swallow tail or Beak nose for example.

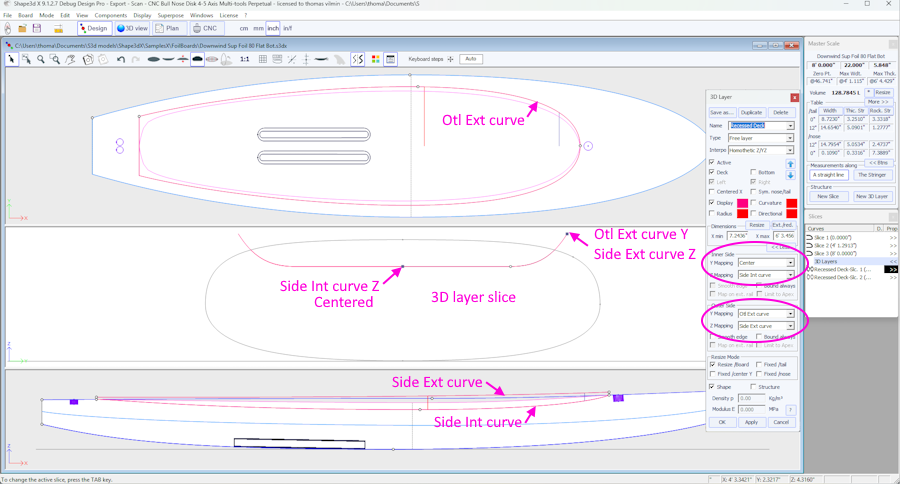

Here are some exemples of Inner side and Outer side mapping choices:

In this exemple above the Inner side Y is set to center, so the slices start on the center axis.

And the Z is set to Side Int curve, so the Side Int curve is displayed in the side view.

The first control point of the layer slices is fixed at Y = 0 and it's vertical position Z is set by the Side Int curve.

The Outer side Y is set to Otl Ext curve,

so the Y position of the last control point of the slices is set by the Otl Ext curve displayed in the top view.

The Z of the Outer side is set to Side Ext curve,

so the Side Ext curve is displayed in the side view,

and the Z position of the last control point of the slices is set by the Side Ext curve.

In the resulting shape the volume between the deck of the original board slices and the 3D layer slices

is removed here.

Note that if there's no intersection between the slices of the 3D layer and those of the board, the 3D layer has no influence on the final shape then.

This could happen here for exemple if you set the Side Int curve too high,

or the Side Ext curve too low.

In this exemple above the Inner side Y is set to Otl Int curve

displayed in the top view. And the Z is set to Bottom.

So the first control point of the layer slices (the closest to the center) has its Y position set by the Otl Int curve

and it's vertical position Z stuck the the bottom of the board slices.

The Outer side Y is set to Otl Ext curve,

so the Y position of the last control point of the slices is set by the Otl Ext curve displayed in the top view.

The Z of the Outer side is set to Deck,

so the Z of the last control point is stuck the the deck of the board slices.

Note that the Otl Int curve crosses the center axis to go to negative Y values, so the result is cut at Y = 0.

In the resulting shape the volume between the deck of the original board slices and the 3D layer slices

is removed here.

In this exemple above the Inner side Y is set to Otl Int curve

displayed in the top view. And the Z is set to Deck.

So the first control point of the layer slices (the closest to the center) has its Y position set by the Otl Int curve

and it's vertical position Z stuck the the deck of the board slices.

The Outer side Y and Z are set to Apex curve,

so the last control point of the slices is stuck to the Apex point of the original board slices.

Note that the Otl Int curve crosses the center axis to go to negative Y values, so the result is cut at Y = 0.

In the resulting shape the volume between the deck of the original board slices and the 3D layer slices

is removed here.

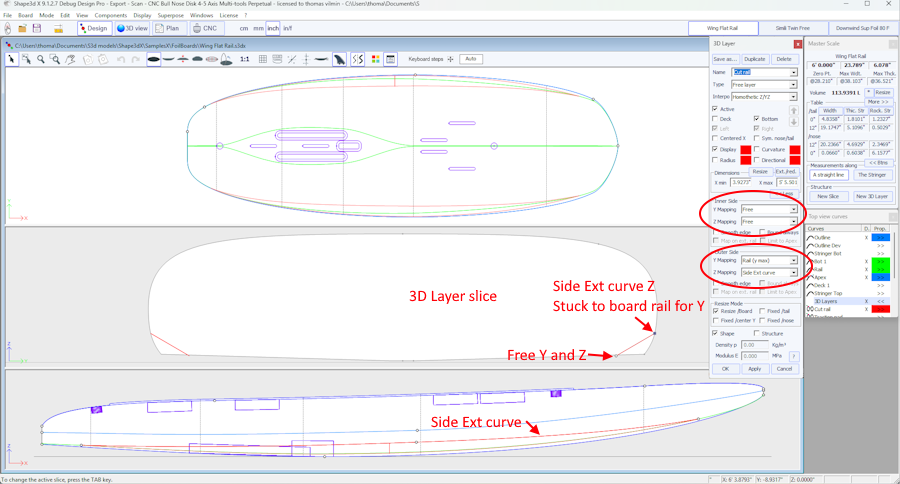

In this exemple above the Inner side Y and Z are set to Free,

so the first control point of the layer slices (the closest to the center) is not fixed horizontally nor vertically.

The Outer side Y is set to Rail (y max),

and the Z to Side Ext curve,

so the last control point of the slices is fixed vertically by the Side Ext curve curve,

and stuck horizontally to the board slices.

In the resulting shape the volume between the deck of the original board slices and the 3D layer slices

is removed here.

Note that if there's no intersection between the slices of the 3D layer and those of the board, the 3D layer has no influence on the final shape then.

This could happen here for exemple if first control point of the slices, which is free, is positionned too high here.

The option Bound always will connect the edge of the layer to the original shape vertically (or straight to the Apex if larger than the board). Note that when this option is not use and if the extremities of the layer slices are not stuck to the Bottom or Deck, then the final shape of the layer is the result of the intersection of its slices with the original shape slices. If no intersections the layer is not taken into account.

The other options and the interpolation method, and the design of the slices, are the same as for Center layers and Twin layers.

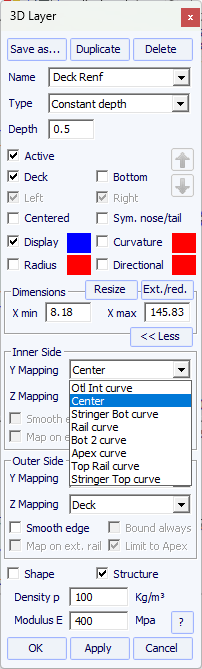

- The Constant Depth layers ![]() are shapes that are defined by

their depth and their outline designed in the outline view.

are shapes that are defined by

their depth and their outline designed in the outline view.

For the Inner and the Outer sides you have the choice to use an Otl curve, or set it to the Center or any of the Definition curves of the original shape (i.e. Apex curve, Rail curve...).

The outer side of the layer can also be mapped on the opposite side (i.e. Bottom for a Deck layer, or Deck for a Bottom 3D layer).

The option "Smooth edge" extends the layer to get a smooth transition at the edges instead of an angulous transition.

Note that you can apply a Constant Depth 3D layer on the whole board by setting xmin=0 and xmax=board length,

Inner mapping Y Center and Z Deck, Outer mapping Y Center and Z Bottom.

You can use such a layer evaluate the weight of the fiberglass stratification for exemple:

set the thickness (depth) about 1mm and the Density p.

For fiberglass lamination, a typical value is about 2000 Kg/m3.

You can also let the thickness (depth) to 0, and then the density p will be the surface density.

For a 1mm thick fiberglass lamination, a typical value is about about 2 Kg/m2.

Then you'll get the weight in the Plan mode / Volume and Surface distribution.

- The Side Cut layers ![]() are shapes that are defined by a curve Side in the Side view that cuts the board horizontaly.

are shapes that are defined by a curve Side in the Side view that cuts the board horizontaly.

- The Vertical Cut layers ![]() are defined by their outline curves Otl Int and Otl Ext

designed in the top view, that cut verticaly and removes the volume between them.

are defined by their outline curves Otl Int and Otl Ext

designed in the top view, that cut verticaly and removes the volume between them.

The 3D layers can be saved in a separated file, and then loaded in another board file using the menu "3D Layers" -> "Load 3D layer". They can also be deleted from the board design.

Several 3D layers can be added one on the other.

There are several Resizing options that let you choose whether the 3D layer should be resized proportionally in length or width when the board is resized.

The 3D layers can be define as a "Shape" or as a "Structure"

(i.e. a reinforcement patch for exemple).

In the second case you can define the density so that it is used in the final weight computation, and the elastic modulus for the stifness computation.

If the 3D layer is defined as a "Structure" and not "Shape" ,

then it is not taken into account in the auto-positioning of the plugs.

You can download some sample files in the Warehouse.

Note that the 3D Layers need the Pro option to be used.

![]() Editing

mode

Editing

mode

![]() Group

selection

Group

selection

This feature allows selecting a group of control points or a group of guidelines if the guidelines are shown on screen.

![]() Zoom

Zoom

![]() Zoom

Window

Zoom

Window

In this mode, if you draw a rectangle with the mouse, the view is enlarged and the contents of the rectangle are fitted to the pane view. Right click to zoom back.

![]() Move

Move

Move the drawing with the mouse.

These functions are also present in the menu "Mode".

![]()

![]() Copy and paste

Copy and paste

You can copy the active curve (outline, rocker, thickness)

by clicking on the ![]() button

and paste it with

button

and paste it with ![]() on another curve

of the same board or of another board.

on another curve

of the same board or of another board.

You can also copy a slice and paste it on another one. If you paste it on the slice of another board they need to have the same number of control points per slice.

For exemple, to get smooth lines at the nose when it's veru thin, it's recommended to copy the slice next to the nose slice and paste it on the nose slice.

It's easier than to edit the nose slice which can be very small.

Note that if you select one control point of the copied curve, and then one point of the other curve, it will copy-paste the whole curve.

But you can also copy-paste just a section of curve by selecting the control points you want (press the Shift or Control keys while selecting the points).

It's also possible to copy and paste just one control point, but in this case you need to use the function "Paste on selected point"

in the Control points menu.

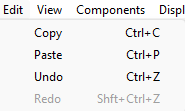

Copy and paste can also be done pressing the keys Ctrl+C and Ctrl+V (see The Shortcuts).

These functions are also present in the menu "Edit".

![]()

![]() Undo

and Redo

Undo

and Redo

Undo the last actions (add, move or delete point or guidelines...). Now with Shape3d X you can also Redo the last action you Undo.

![]()

![]()

![]()

![]() Change

view

Change

view

You can change the order of the views: put slices on top instead of outline for example. You can also change the size of each pane by moving the bar between the panes.

![]() Top view

Top view

The Top view allows seeing all the definition curves from the top.

![]() Side view

Side view

The Side view allows seeing all the definition curves from the side.

![]() Thickness view

Thickness view

The Thickness view allows displaying the distance between two curves; like the thickness between the bottom and the deck stringer curve for example.

![]() Slices

Slices

![]() Wire view

Wire view

This view is very useful to check the smoothness of the lines and enable you to move the control points of the slices directly on the 3D view of the board. Click on a point to show its tangents and to move it. Be careful, it's not as easy as in the 2D view!

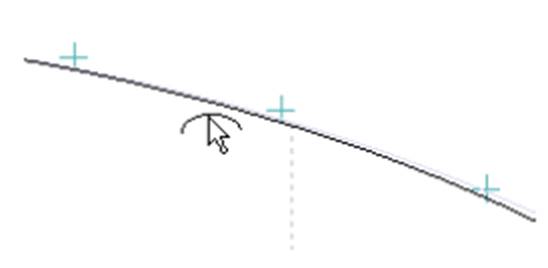

To rotate the board, move your cursor in a free area and you will

see the symbol of the cursor will change too ![]() .

.

By moving the board with the mouse, you can check the smoothness of the curves, as it gives you a "compressed view" of the curvature.

Rotate View

Rotate View

Rotate the selected view to display the design vertically.

![]() Full Scale mode (1:1)

Full Scale mode (1:1)

Shows the curves in the selected panel in real size. Some screens need a correction coefficient that you can define in the Preferences window (menu File)

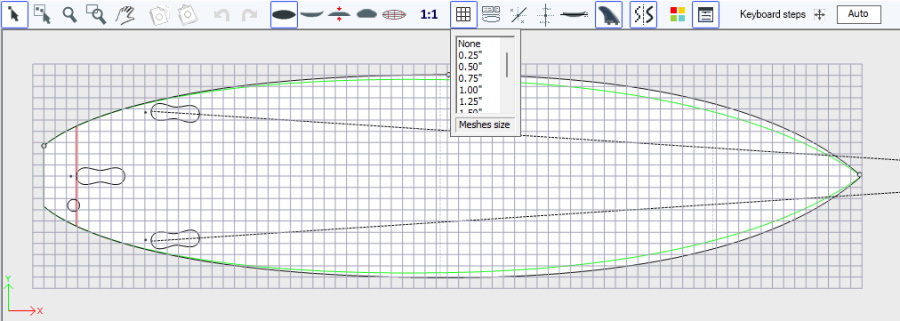

![]() Grid

Grid

Click on this button; choose the step of the grid and display a grid on the active pane.

![]() Rail Master

Rail Master

The Rail master will display the measurements in the selected panel, as well as the percentage of change since last time you saved the file.

![]() Guidelines

Guidelines

This button displays the guidelines associated to each edited curve. We'll see in the Menu chapter how to add, delete or move a guideline, and also how to automatically fit a curve to its guidelines.

Note that the Guidelines need the Design option to be used.

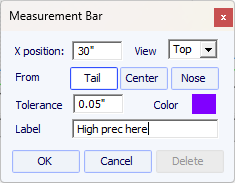

![]() Measurement bars

Measurement bars

This button allows displaying the measurement bars that gives the measurements of all the displayed curves of a panel at a defined distance from tail or nose.

You can add labels to the measurement bars and the expected precision.

Note that the Measurement bars need the Design option to be used.

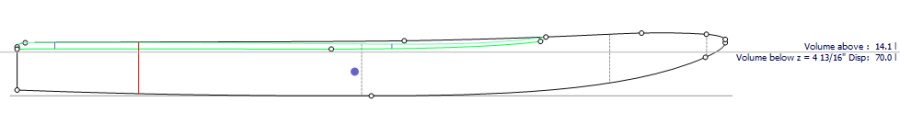

![]() Buoyancy line

Buoyancy line

This button displays the Buoyancy line in the Side view panel. The Buoyancy line gives the volume below and above a chosen height.

Note that the Buoyancy line need the Pro option to be used.

![]() Fin boxes

Fin boxes

This button displays the boxes, if you have defined fin boxes, or foot straps or mast foot for your board (Properties/boxes), you can move them with the mouse. See menu Components/Plugs for more details.

![]() Antialiasing

Antialiasing

Antialiasing gives smoother curves, but increases the computer load and can make the mouse move slower.

![]() Colors box

Colors box

Press this button to change the color of the background, the board, or default color of the curves. You can also change the curves line width.

![]() Dialog boxes

Dialog boxes

Press this button to have the Master Scale, Curves List, Guidelines List and the Point Properties boxes shown on screen, or disappear.

![]()

![]()

You can define the steps of the keyboard displacements. If you let it blank, it will go back to Auto. With Auto, the more you zoom in the smaller the steps. If you press the Shift key the steps will be 2 times smaller. With Ctrl it will be 4 times smaller. And Shift+Ctrl makes them 10 times smaller.

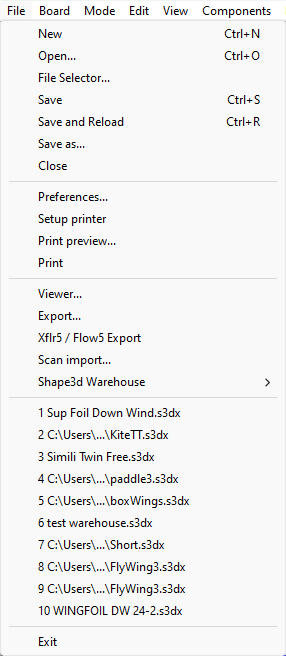

Most of the options presented in the Menu are also accessible in the toolbar. However, some of them are not:

"Save" will save your file with the .s3dx extension, which is the Shape3d X format.

The .s3dx files cannot be opened by Shape3d V8 or older! This is because the VX files can contains objects like the 3D layers or edited curves that are not handled by Shape3d V8 and older.

But you can save your files with the .s3d extension in the V8 format using "Save as..."

In this case, if your board has 3D layers, or multi-edited curves, they will be removed from the .s3d V8 file.

The menu item "Preferences..." opens the preferences dialog box.

The "Print" item allows printing the current view.

The option "Viewer" opens the viewer that allows visualizing data files in 3 dimensions.

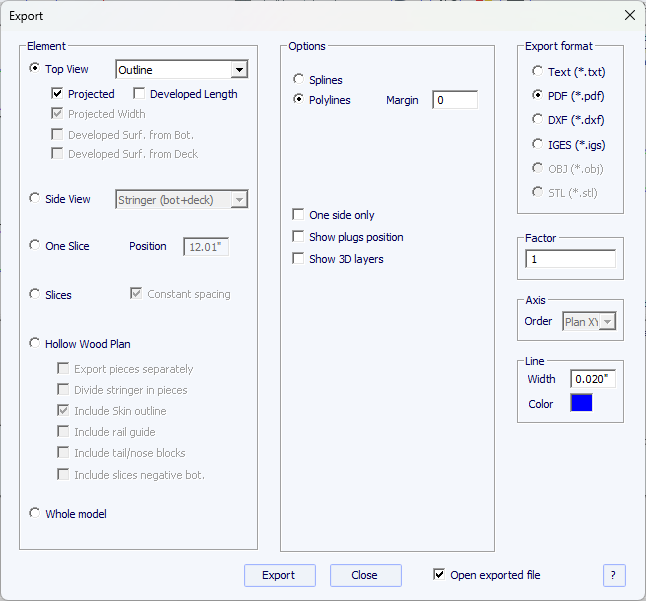

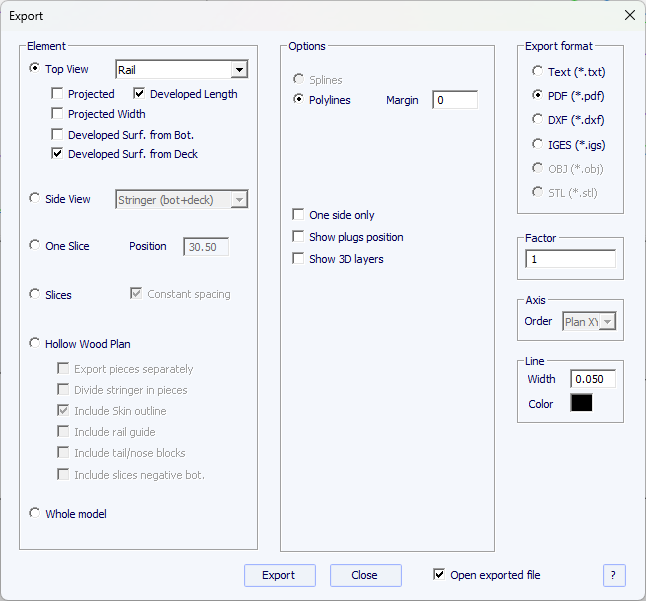

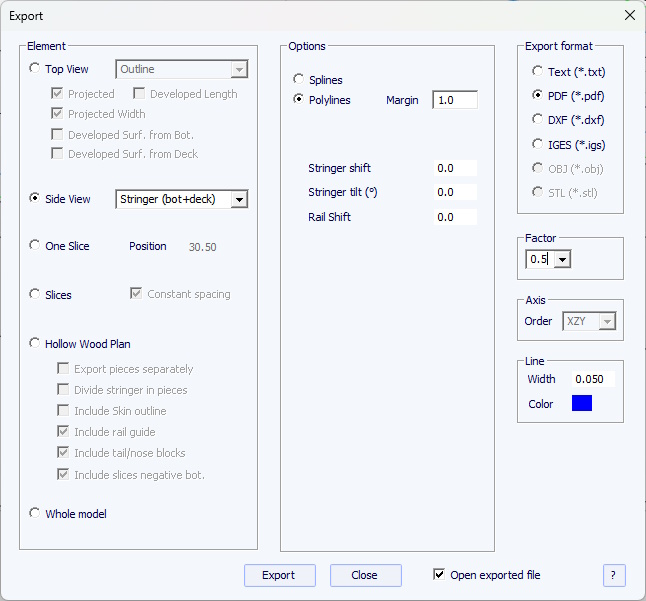

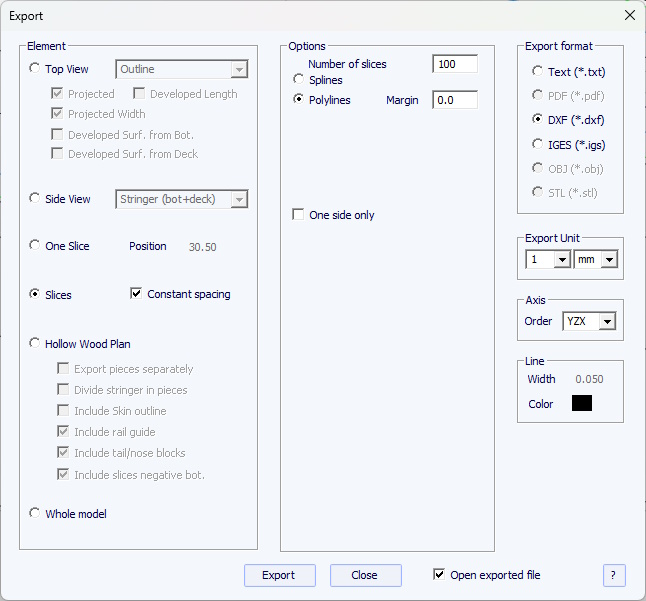

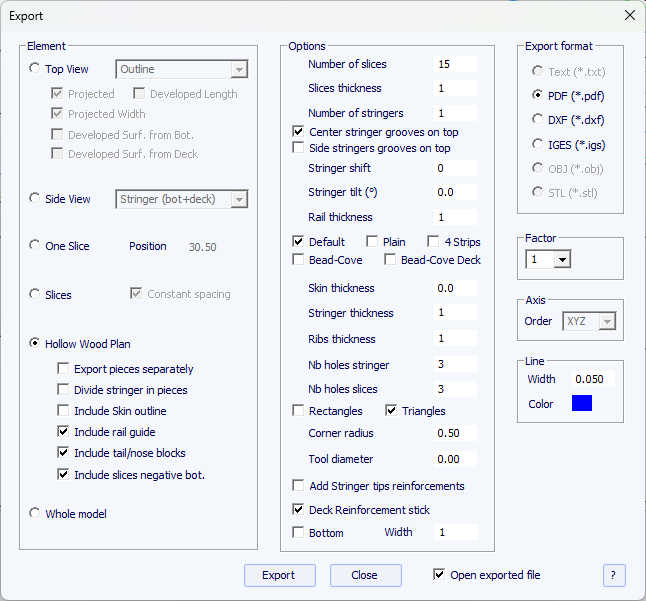

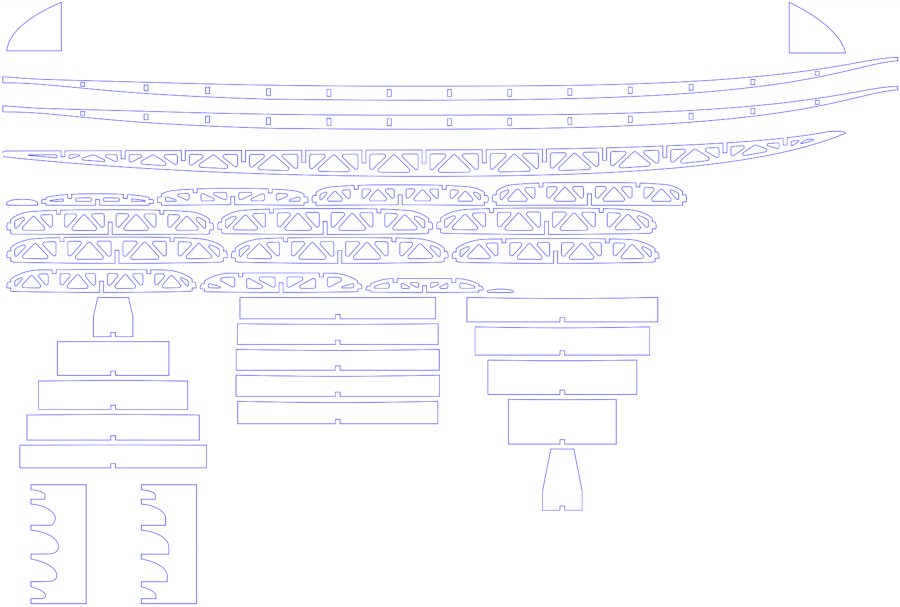

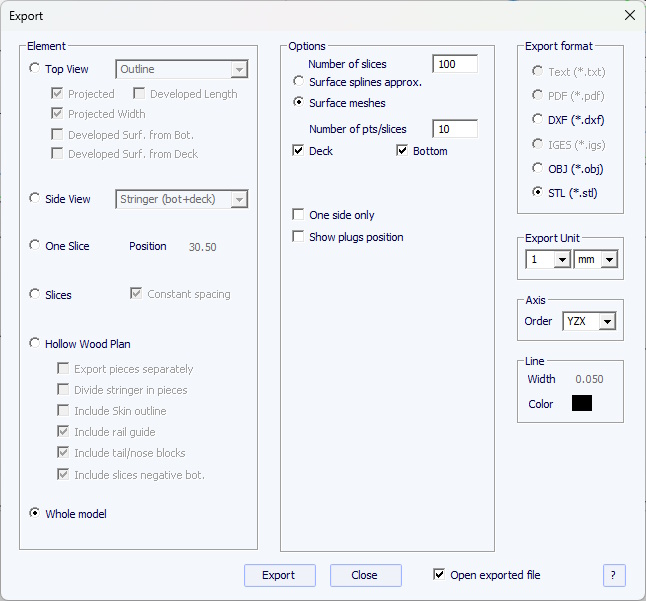

The option "Export..." opens the Export dialog box.

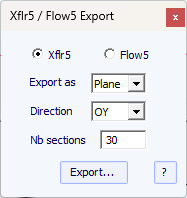

The option "Xflr5 / Flow5 Export" opens the Export dialog box for the Xflr5 or Flow5 softwares, that allows computer the lift and drag of an hydrofoil (see chapter Slices).

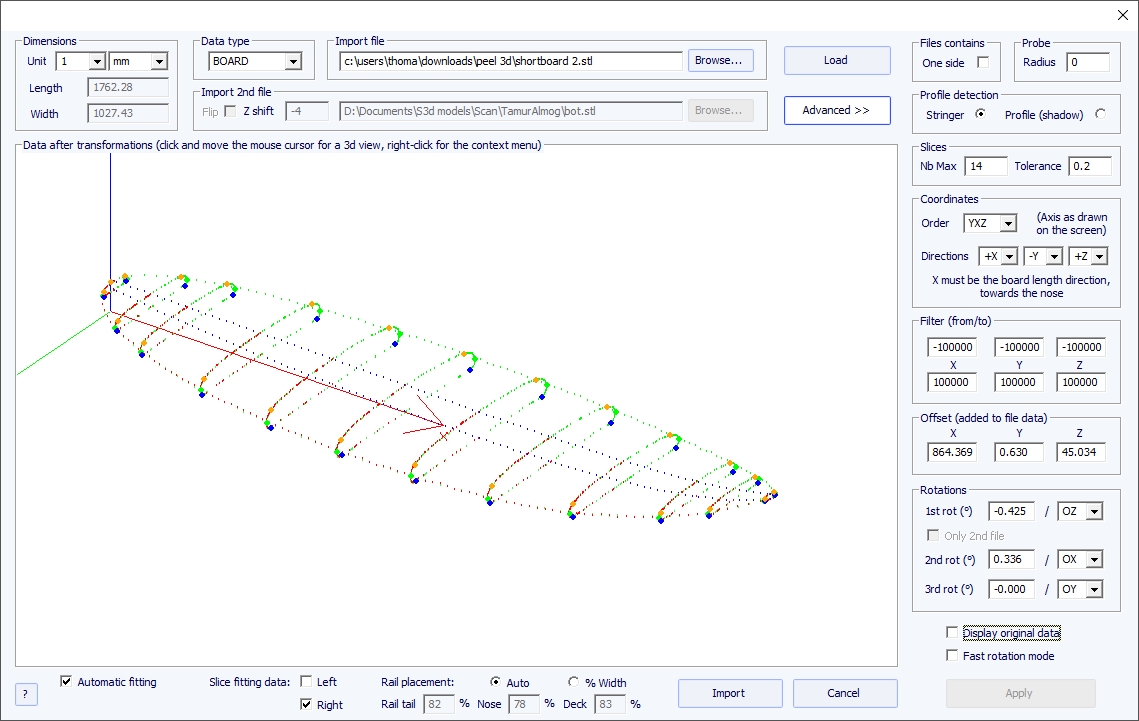

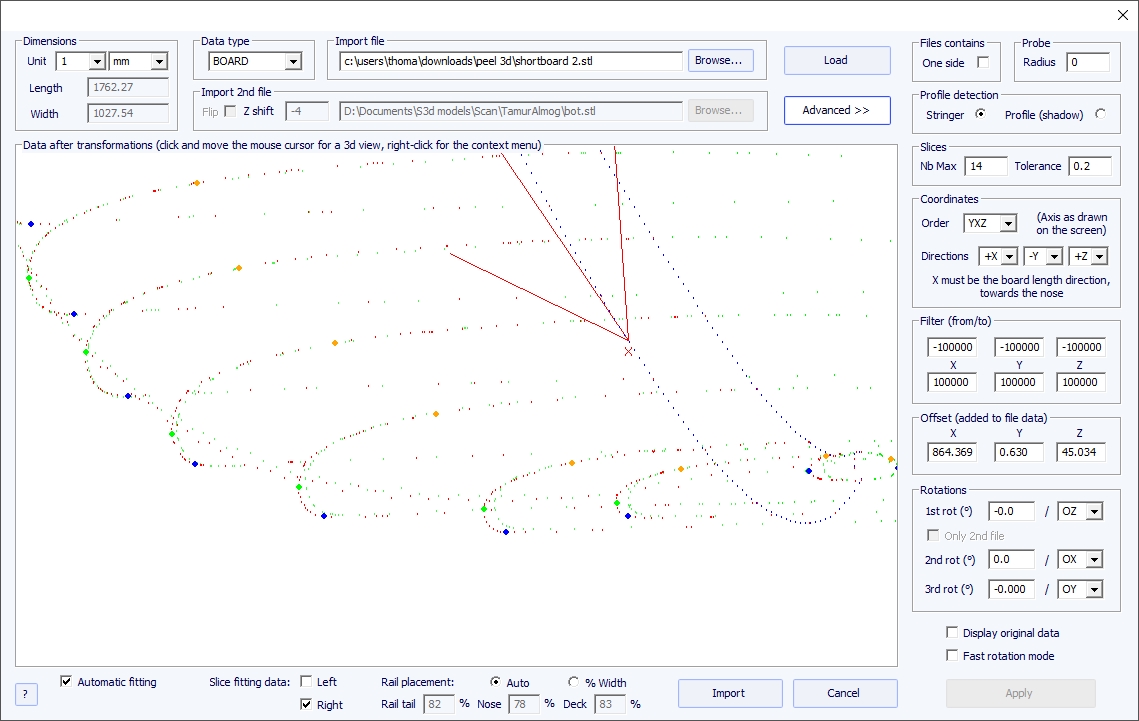

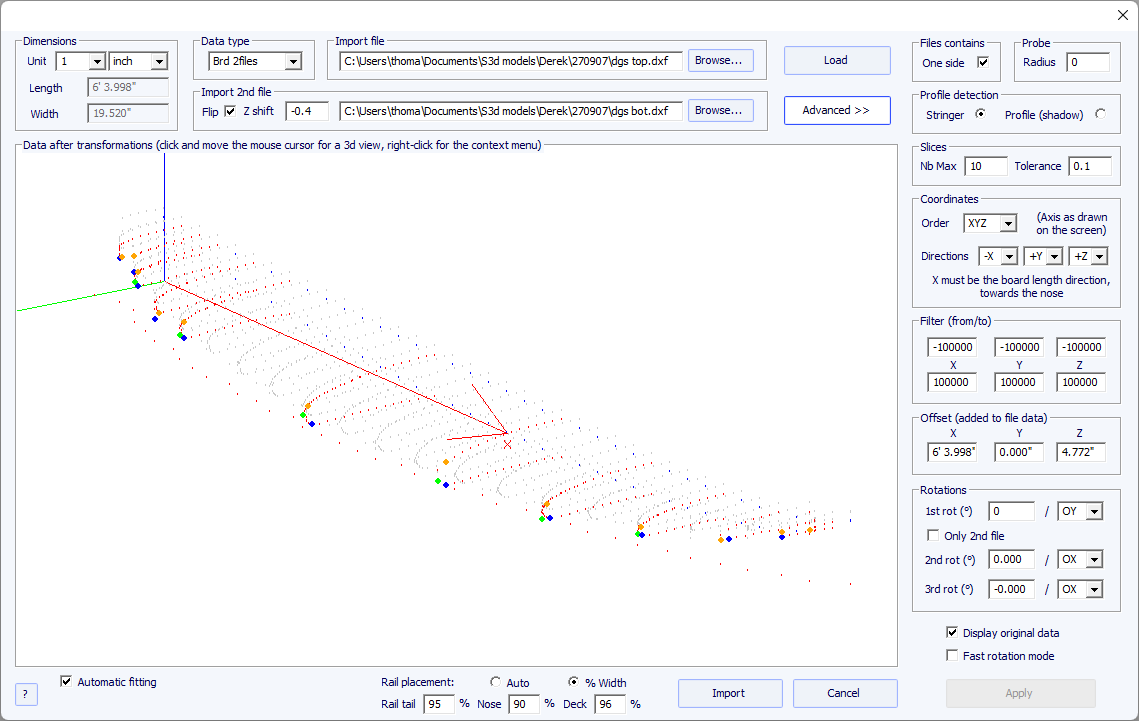

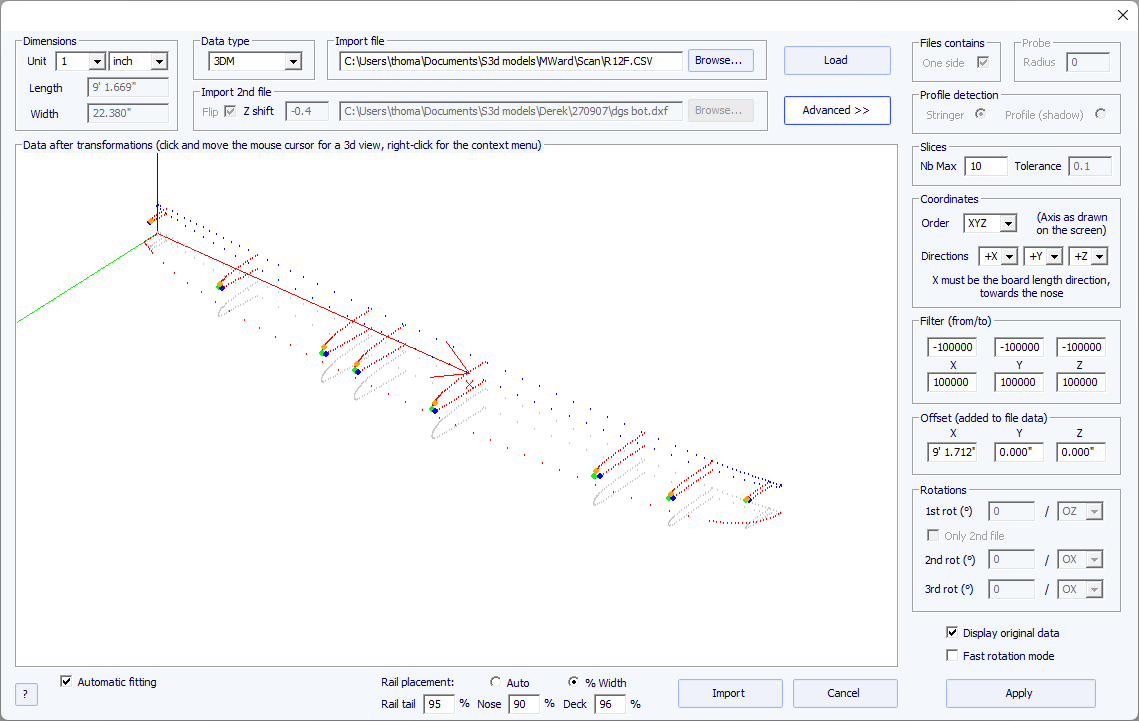

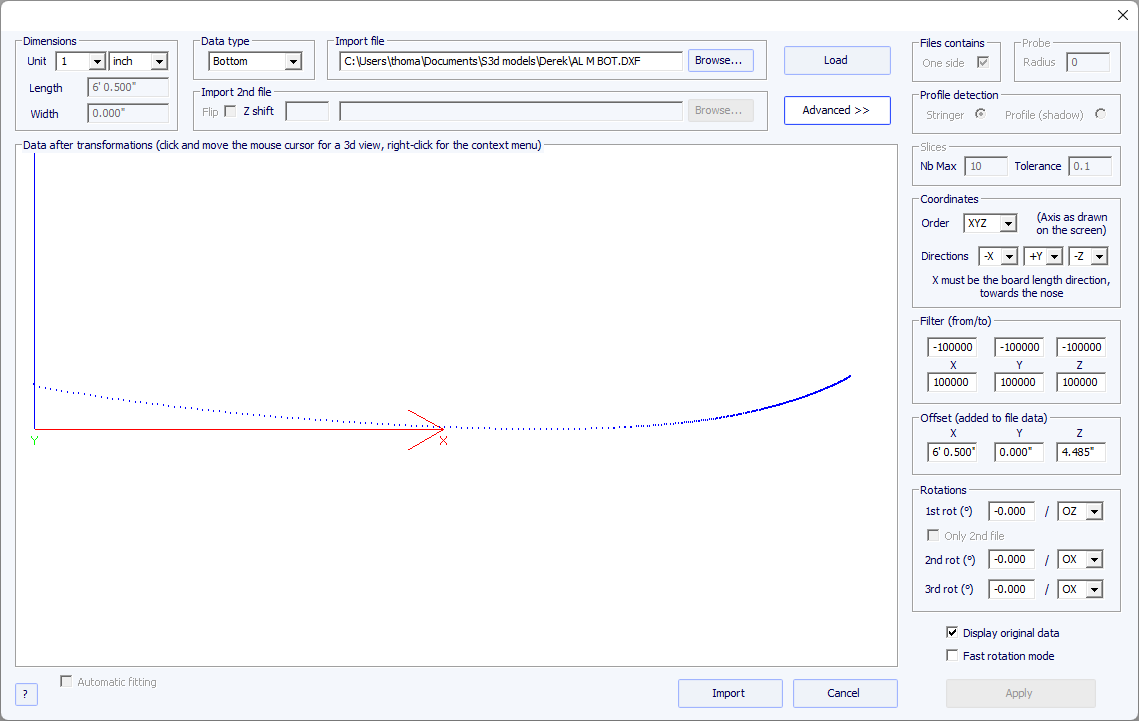

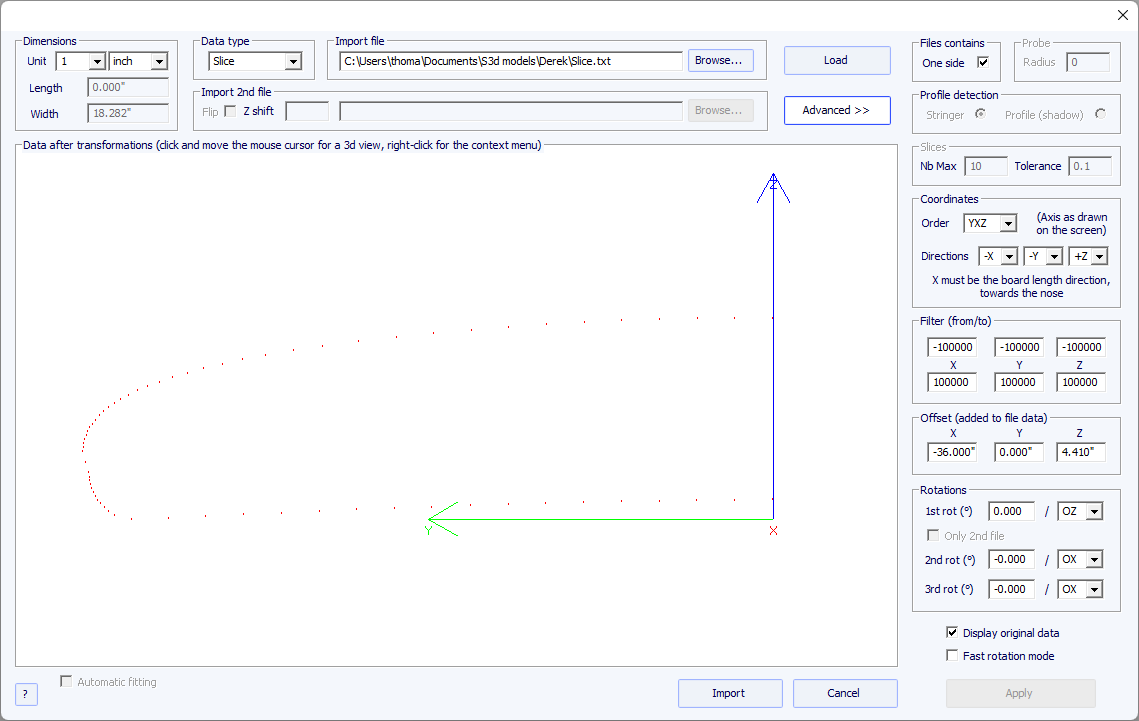

The option "Scan import..." opens the Scan dialog box.

The "Shape3d Warehouse" allows downloading sample boards and sharing your boards on the ../Warehouse web site.

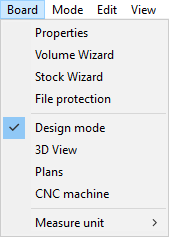

The menu "Board" allows displaying the Properties window of the board (see Size and Parameters).

- It also allows opening the Volume Wizard (see Master Scale window).

Note that the Volume Wizard needs the Design option to be used.

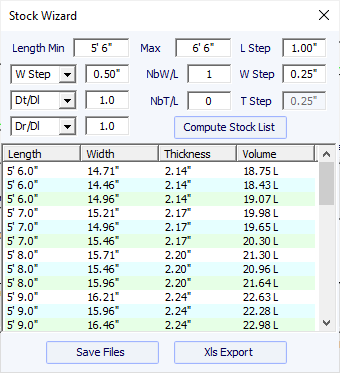

- And the Stock Wizard that allows generating a list of dimensions with volumes for a range of length and width/thickness variations. It can save all the stock files in a target folder:

While the length is resized, you can either set a fixed width variation W Step, or set the width variation over length variation ration Dw/Dl. By default Dw/Dl for constant proportions resizing.

You can set the thickness and rocker variations the same way.

Then, for each stock length, you can create several stock widths setting the NbW/L field larger then 0. If NbW/L is set to 1, at each length you'll get a stock board with the width lowered by W Step

and one with the width encreased by W Step. You can do the same with the thickness.

Note that the Stock Wizard needs the Pro option to be used.

- You can access the File protection tab of the Size and Parameters window directly from this menu.

- This menu also allows changing the general mode and the measurements unit.

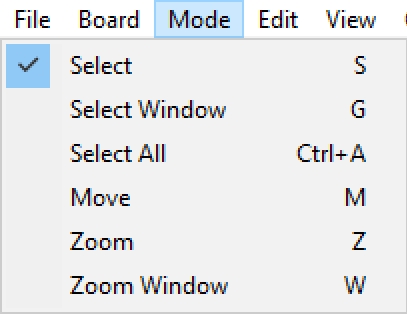

The menu "Mode" allows changing the selection mode in the design panels.

The menu "Edit" ) contains the Copy-Paste functions, and Undo-Redo.

The menu "View" allows changing the view of the active panel (see toolbar). It also includes the option to display the board vertically.

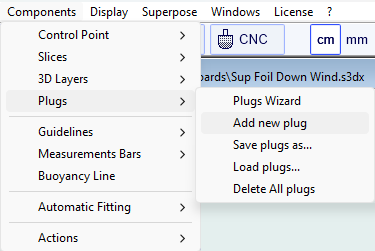

The menu "Components" allows modifying the design components of the boards.

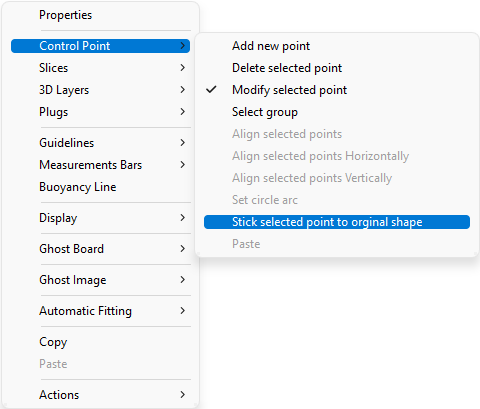

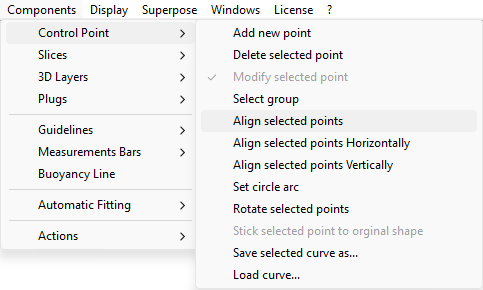

"Control points" allows adding a new control point, deleting the selected point, modifying the selected point, or activating the Group selection function.

If several control points are selected, "Align selected points" allows aligning several points and tangents of a curve. The points can also be aligned horizontally or vertically.

"Set circle arc" modify the selected curve sections (2 or more control points) to approximate a circle arc (i.e. constant curvature).

"Rotate selected points" allows rotating the section of a curve, or the whole curve in its plan. It can be used to tilt the cross section of an hydrofoil for exemple.

"Stick selected point to original shape" allows positioning the control point of a 3D layer's slice right on the original slices.

"Stick selected point to Ghost" allows positioning the control point on the closest point of the loaded Ghost.

"Paste on selected point" is active when one control point has been copied, and only one other control point is selected. It allows for copy-pasting only one point instead of the whole curve.

The selected curve can be saved in a separate file using "Save selected curve as...". It can also be loaded from a curve file or a board file using "Load curve...".

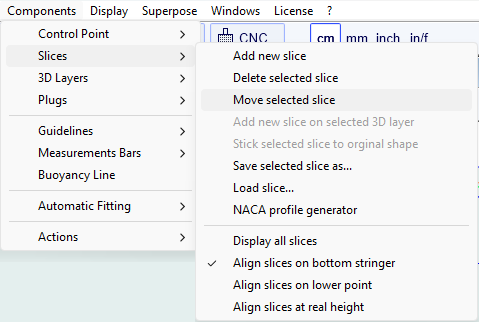

"Slices" allows adding a new slice, deleting or moving the selected slice.

The selected slice can be saved in a separate file. It can also be loaded from a slice file or a board file.

This menu also allows you to modify the slice display options:

All Slices shows all the slices at once in the Slice panel.

There are 3 choices for the vertical alignment of the slices when several of them are displayed, or when a ghost board is displayed:

Align slices on bottom stringer, Align slices on lower point, and Align slices at real height.

This option will also change the Z value of the slice control points displayed in the control points properties window.

- With Align slices on bottom stringer the center point of the bottom of each slice will be set at Z=0.

- With Align slices on lower point the lowest control point of each slice will be set at Z=0.

- With Align slices at real height the slices will be placed at their real height as shown in the side view.

Note that you need to select the option Aligned on real height to be able to move the slices of a ghost up of down.

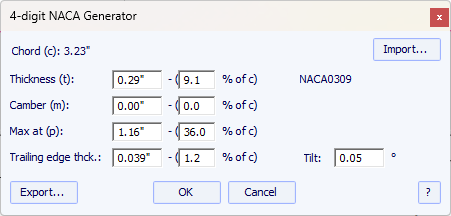

Note that the NACA window needs the Pro option to be used.

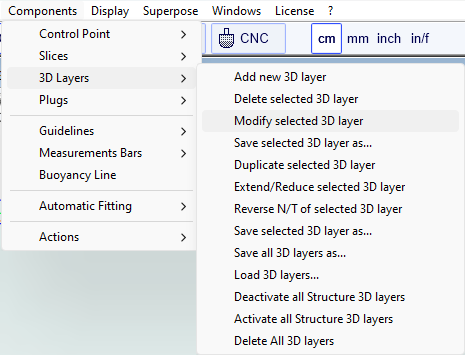

"3D Layers" allows adding a new 3D layer, deleting or moving the selected 3D layer, or saving the selected 3D layer in a file and loading a 3D layer from a 3D layer file or another board file.

The selected 3D layer can be duplicated, extended/reduced or reversed.

You can also save all the 3D layers in a new file, and then load them in

another board file.

Note that the 3D layers need the Pro option to be used.

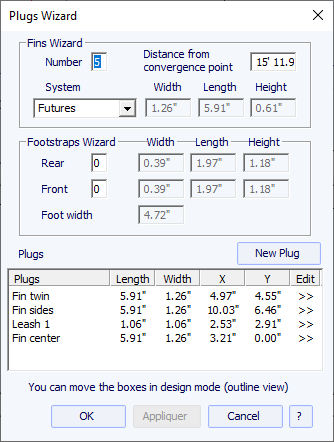

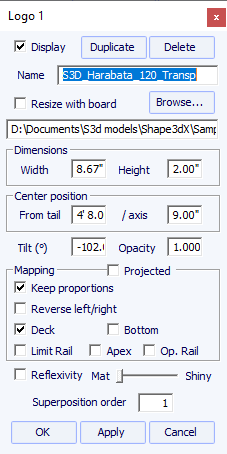

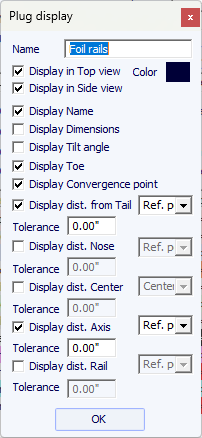

"Plugs" allows adding a new plug, or modifying the selected plug. It also allows saving plugs in a separated file, or load plugs from a plug file or another board file.

The "Plugs Wizard" allows adding several fin plugs or foot straps plugs at the same time.

You can find a good guide for fin placement on McKee Surf website: http://www.mckeesurf.com/?page_id=267.

For a surfboard with thrusters, the convergence point can be positioned along the stringer.

For a sail board, only one fin box can be defined. On the other hand, the number of foot straps is not constrained.

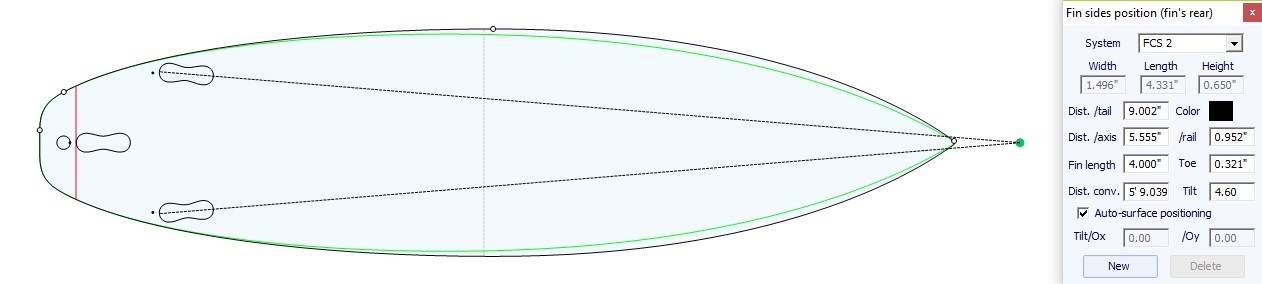

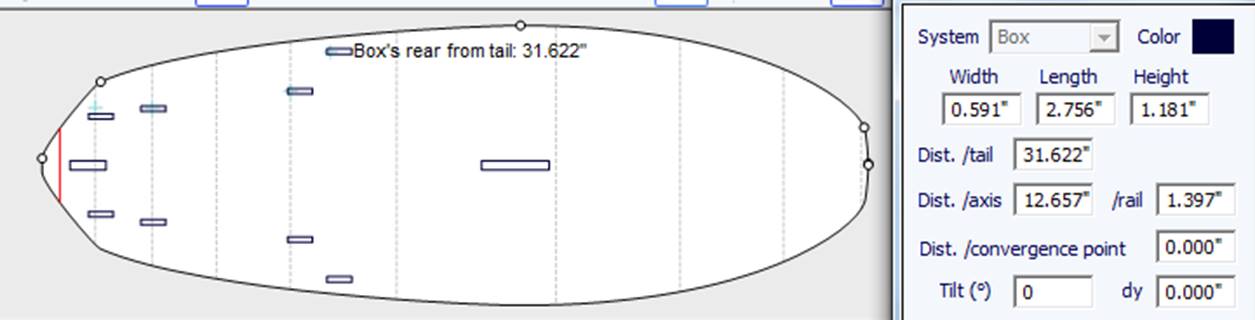

Additional plugs can be added with the button New Plug. The new plugs can be boxes, leash plugs, or fins plugs of any type.

The new plug can be of any standard system, or a simple box.

It can be a single plug, "Centered Y" or not,

or twin boxes "Sym. right/left" (one on each side of the board).

The option "Sym. nose/tail" also allows duplicating the plug, placed on the tail, to the nose.

For simple boxes with rounded corners you can define a corner radius.

For cylinder plugs, the length can be different from the width to give oval shape.

In case of resizing of the board, the X position of the plug can be set "Fixed to tail" or "Fixed to nose".

If none of these boxes are checked, the X poition of the plug will change proportionaly to the length of the board.

In the same way, the Y position of the plug can be set "Fixed to center" or "Fixed to rail", or none.

The "Reference point" can either be the center of the back of the plug, with dx and dy shift, or the center of the plug.

For standard fin systems like FCS or Futures, the reference point is set by default and corresponds to the rear of the fin.

The "Auto-surface positioning" option place the plug right at the surface of the board.

Note that the 3D layers defined as "Structure" are not taken into account in the auto-positioning of the plugs.

If this option in unchecked, you can set the tilt angles, relatively to the Ox axis and to the Oy axis.

You can define the weight so that it is added to the total weight of the board.

The plugs are displayed in the Top view and in the Side view. The list of plugs is also added to the list of curves.

The X in the list allows you to display or hide each plug.

When you click on a plug in the Top view panel, the label of the plug is displayed, and the properties window appear on the side.

The label can be selected and moved with the mouse or keyboard. The position of the label will be the same in the print sheet of the Plan mode.

The System, dimensions and position can be changed.

The tilt angle can also be modified in 3 different ways:

- Change the Toe, or the Fin length (Toe/Fin length = tan(Tilt))

- Change the Distance to convergence point (Dist. axis/Dist. conv = tan(Tilt))

- Or change the Tilt angle in degrees

If the "Auto-surface positioning" option is not checked, you can set the tilt angles, relatively to the Ox axis and to the Oy axis.

Note that the Plugs need the Design option to be used.

"Guidelines" allows adding a new guideline, deleting or moving the selected guideline, or activating the Group selection function. "Default guidelines will create" guidelines at fixed distance from tail and nose that correspond to the selected curve. "Guideline wizard" open the Measurement Wizard window (see New board from measurements). "Import guidelines" allows importing guidelines from a file (.dxf, .txt, .asc, .csv, .pim).

Note that the Guidelines need the Design option to be used.

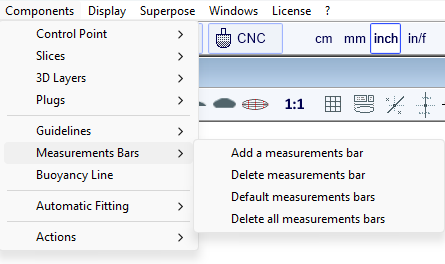

"Measurement Bars" allows adding or deleting a measurement bar. A measurement bar guives the measurements of all the displayed curves at a gives x position from the nose or the tail. "Default measurement bars" will create measurement bars at fixed distance from tail and nose. "Delete all the measurement bars" will delete all the measurement bars in the active view.

Note that the Measurement Bars need the Design option to be used.

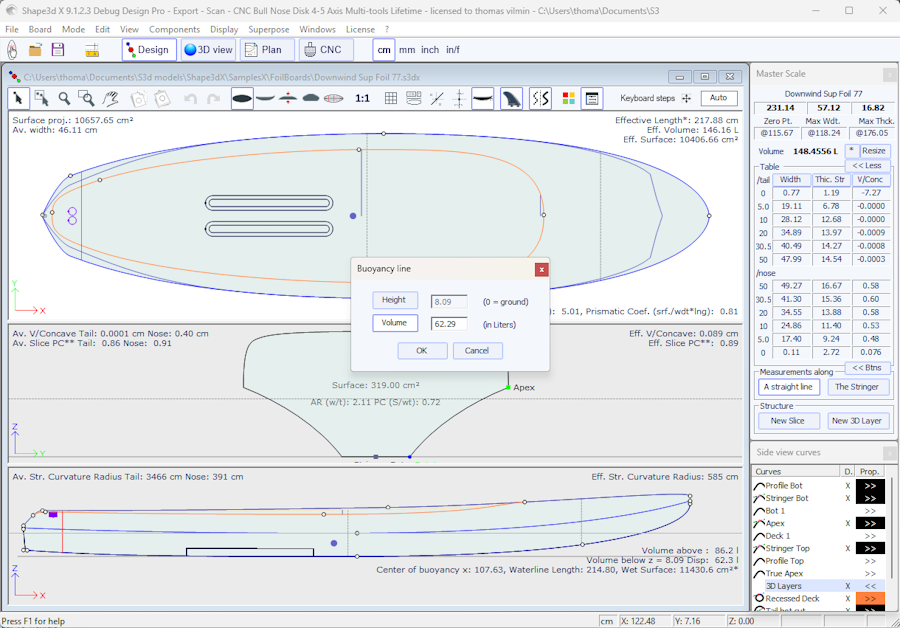

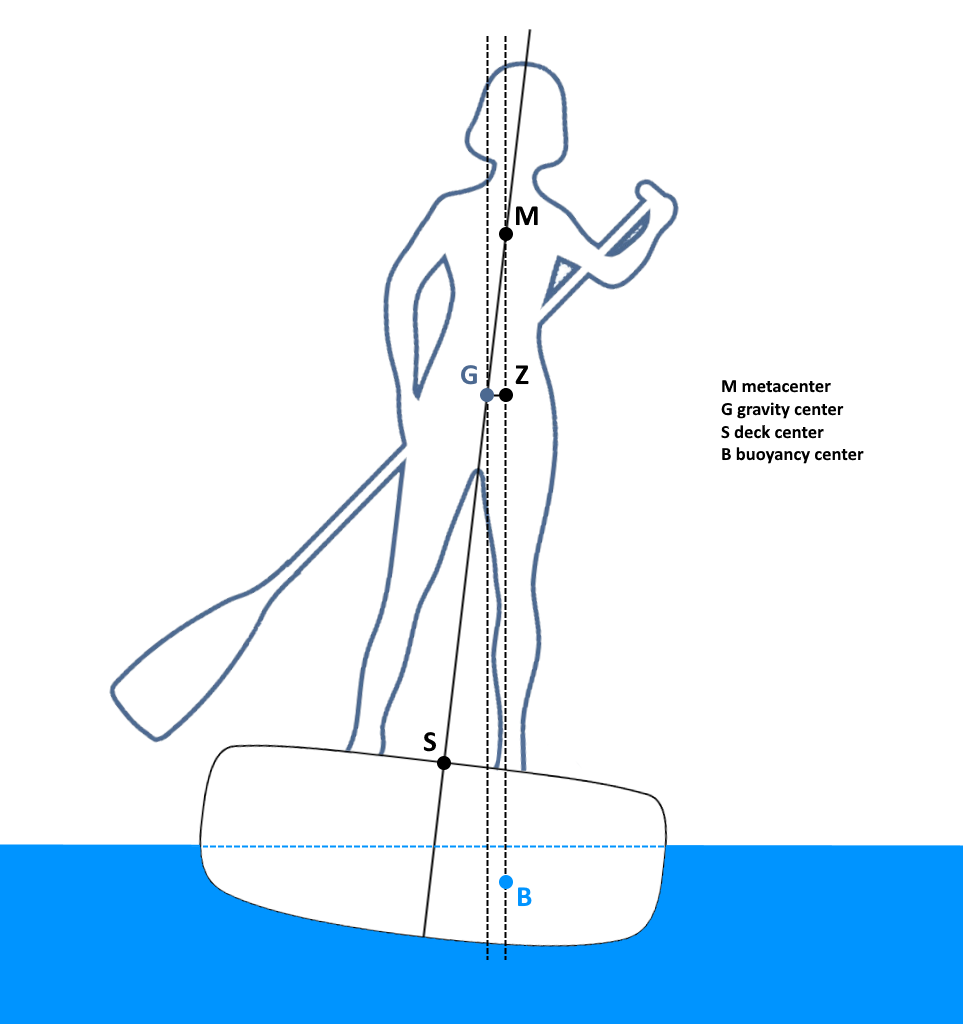

"Buoyancy Line" allows defining the displacement volume, or the height of the buoyancy line.

Once the buoyancy line is defined it will display the volume below and above, as well as the waterline length and the wet surface in the side view.

You'll also see the waterline and the center of buoyancy in the top view.

Note that in order to float, the volume of the board in Liters must be larger than the total of the weight of the rider plus the weight of the board in Kg.

To evaluate the buoyancy line, the buoyancy volume must be set equal to the total of the weight of the rider plus the weight of the board in Kg.

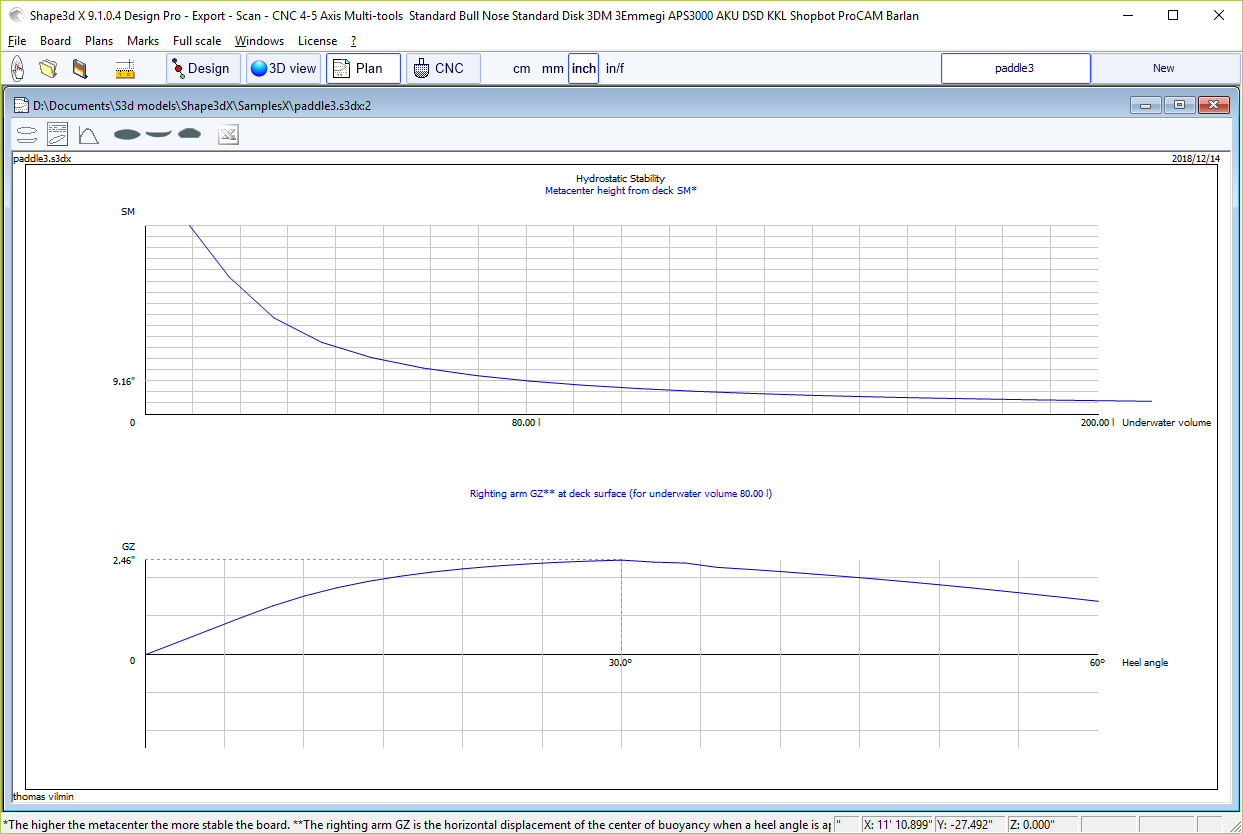

Shape3d also gives the "Metacenter height", which is an indication on the lateral stability of the shape

(see Hydrostatic Stability curves in the Plan mode).

Note that the Buoyancy Line need the Pro option to be used.

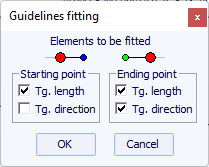

"Automatic Fitting" allows fitting an arc (the section of curve between two control points) or a whole curve to the guidelines.

If you click on a curve section between two control points and choose "Fit selected curve to the guidelines", it will show the Guidelines fitting window.

Then you have to choose if you want to adjust the length or the direction of each tangent, or both. And press OK.

You can also choose to adjust the whole curve, clicking on "Fit the whole curve to the guidelines".

In this case you can choose the number of arcs (i.e. number of control points minus one) that will compose the whole curve. "Auto" will set it automatically, depending on the shape of the curve.

Note that the Automatic Fitting needs the Pro option to be used.

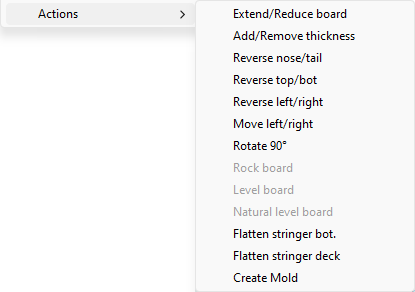

The "Actions" menu contains several items:

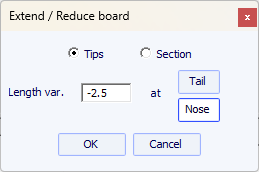

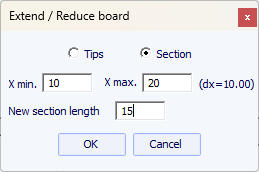

- "Extend/Reduce board" allows increasing or reducing the

length of the board without changing the rest of the board shape (Design option needed).

You can either extend/reduce the "Tips":

- Or a "Section" of the board defined x range:

- "Add/Remove thickness" allows adding or removing some thickness all over the board (Pro option needed). Note that this function will give distortions if the shape is too complex.

- "Reverse nose/tail" changes the board direction (Design option needed).

- "Reverse top/bot" flips the board upside down (Design option needed).

- "Reverse left/right" gives a mirrored board for asymmetric boards (Pro option needed).

- "Rotate 90 Deg" switch the Top and Side views. If the board is not yet asymmetrical, it becomes so (Pro option needed).

- "Rock board" allows tilting the stringer or the board (Design option needed).

- "Level board" rocks the profile view so that the tail and nose rocker are identical (Design option needed).

- "Natural level board" rocks the board so that the rocker is the one the board would have while lying on the ground (Design option needed).

- "Flatten stringer bot." sets the tail and nose rocker to zero, keeping the thickness unchanged. This function sets the bottom stringer straight (Design option needed).

- "Flatten stringer deck" flattens the deck of the board, keeping the thickness unchanged. This function sets the deck stringer straight (Design option needed).

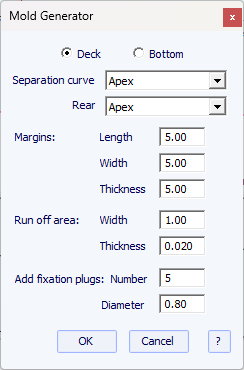

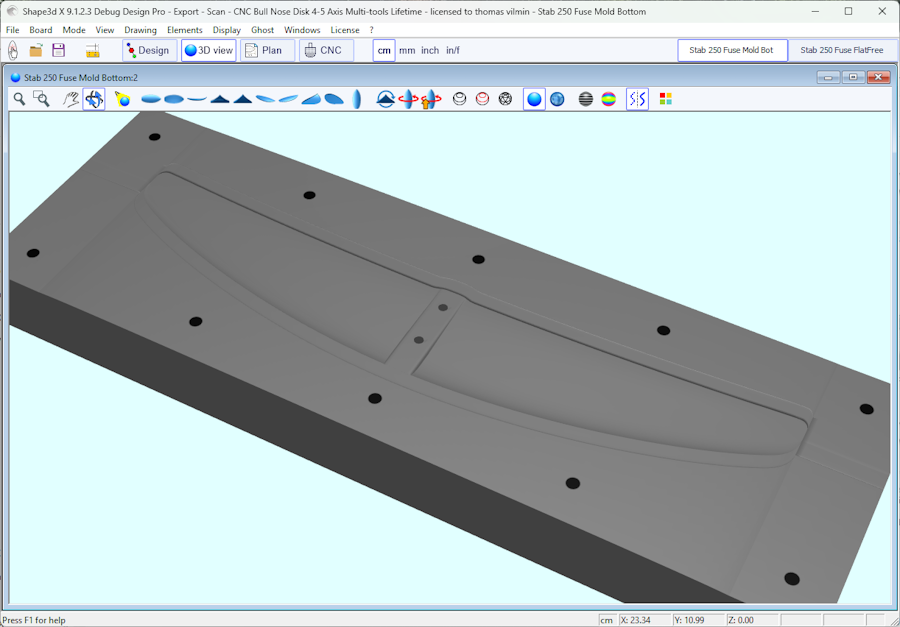

- "Create Mold" opens the Mold Generator window, that allows creating a mold of the deck or bottom of your design (Pro option needed). You can select the separation curves, and add margins and a run off area:

All these function can be accessed through the contextual menu (Right-click).

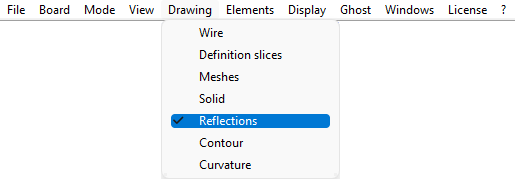

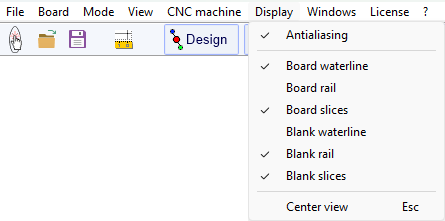

The menu "Display" allows displaying or hiding curvatures, guidelines, measurements bars, waterline, fins plugs, and grid in each design panel.

Apex Always shows a red mark at the widest point of the slices.

Rail Always shows the rail curves on all boards, even if not set as displayed.

Curvature Always shows the curvature of the selected curve.

Hide Curvatures hides the curvates of all curves and slices.

Permanent Tracing shows the measurements of the displayed curves at the position of the mouse even if the left button is not pressed.

Saved Curve shows the original curve when you are moving a control point or a tangent.

Guidelines shows or hides the guidelines.

Measurements Bars shows or hides the measurements bars.

Grid... shows a grid behing the board curves.

Rail Master shows the main measurements in the selected panel.

Buoyancy Line shows or hides the buoyancy line.

Volume Distribution shows the volume distribution curve in the Side view.

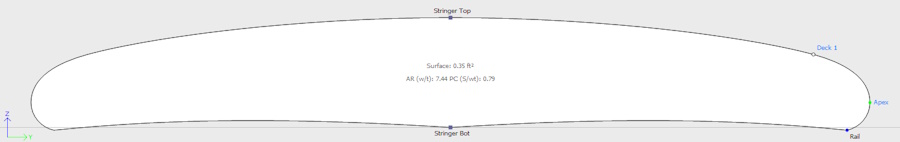

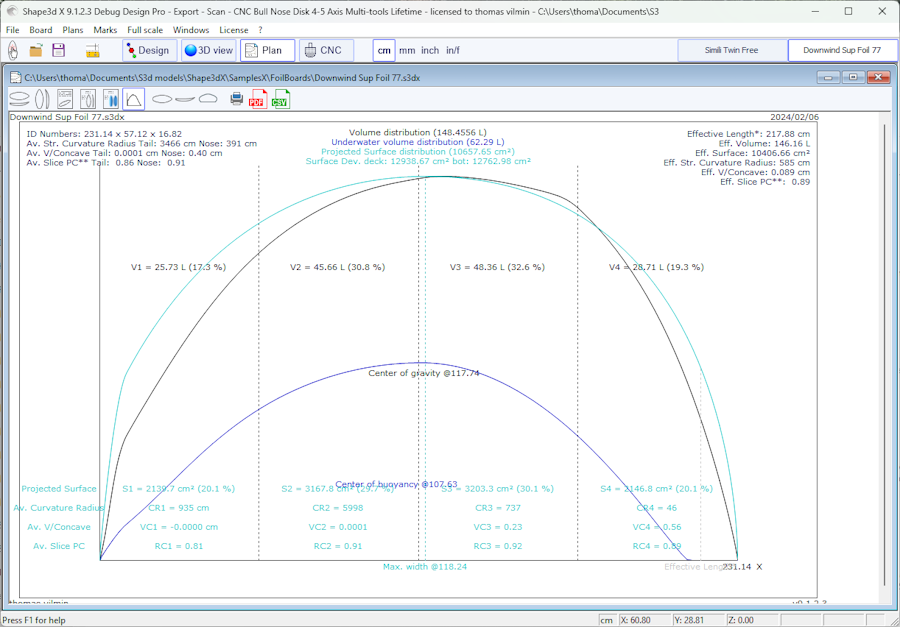

ID Numbers shows main geometric numbers that characterize a board:

- Surface: projected surface of the outline

- Ratio Aspect (lng˛/srf.): squared length over projected surface ratio

- Prismatic Coefficient (surface/wdt*lng): outline surface over rectangle wdt*lng surface ratio

- Av. tail Curvature Radius: average curvature of the bottom stringer curve between the tail and the middle of the board

- Av. nose Curvature Radius: average curvature of the bottom stringer curve between the nose and the middle of the board

- The Slice PC (called Rail Coefficient in previous versions) is the prismatic coefficient of the slices: ratio of the slice surface over the surface of a squared slice

- Effective Length: distance between the tail and the point where the width is half of maximum width

The Effective Length stays the same whether you set a rounder or thinner nose tip.

- Eff. Volume: volume of the board between the tail and the effective length

- Eff. Str. Curvature Radius: average curvature of the bottom stringer curve between the tail and the effective length

- If the Buoyancy line is displayed, the "Maximum section area", the "Waterplan coefficient" and the "Block coefficient" are also given.

Plugs shows the plugs in the selected panel.

Antialiasing display smoother curves

Full Scale (1:1) shows the curves in the selected panel in real size.

Some screens need a correction coefficient that you can define in the Preferences window (menu File).

Save as Default Curves Settings saves the display options

Use as Default Curves Settings loads the saved display options

Always Use Default Curves Settings loads the saved display options each time you open a new file

Hide Points hides the control points to have a clearer view of the curves. You can also press the H key to activate this function.

Show Tangents displays the tangents of all the control points to check the whole curve at once. You can also press the T key to activate this function.

Show Selected Arc Depth displays the maximum depth of the selected curve arc. This function is usefull to measure double concave depth for example. You can also press the D key to activate this function.

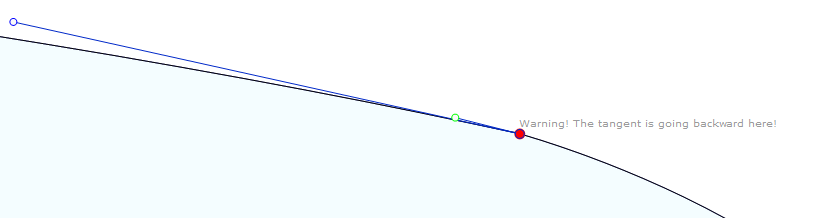

Show Errors releales design mistakes, like superposed slices or superposed control points (big green spot), loops or crossing tangents (big red spot). You can also press the E key to activate this function.

Section Check displays in the Slice panel the cross section of the board at the position of the mouse

in the Top or Side view panels. You can also press the X key to activate this function.

Note that Section Check doesn't change anything if the Permanent Tracing option is on.

Center View places the board at the center of the panel. You can also press the Escape key to

activate this function.

All these function can be accessed through the contextual menu (Right-click).

The menu "Superpose" allows displaying another board or a picture behind the curves.

You can choose another board and load it as a ghost board. The ghost board appears in each view in the color you choose.

It can be moved with the mouse. Press Shift to rotate the ghost in the Side view.

Note that you need to select the option Aligned on real height in the menu Components / Slices

to be able to move the slices of a ghost up of down.

You can also compare the slices flow of the two boards.

Up to 10 ghosts can be loaded at the same time, and you can select the curves you want to display for each ghost in the curves list window.

Note that you can use the ghost in the 3D view and also in the Plan mode.

Press the space bar to hide the ghost.

Note that you can load an STL file as a ghost.

The Ghost Properties window allows movig and rotating the ghost.

Note that you need the Design option to load a Shape3d file as a ghost, and the Pro option to load an STL file as a ghost.

You can load an image in the background to copy an outline or a profile.

The image can then be resized and moved with the mouse. Press Shift to rotate the image.

The image can also be rotated from the Rotation window.

Press the space bar to hide the image.

All these function can be accessed through the contextual menu (Right-click).

Note that you need the Design option to load a ghost image.

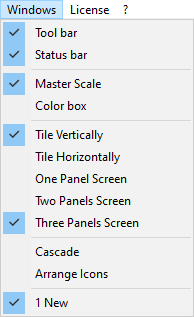

The menu "Windows", allows choosing the screen settings.

The top Tool bar and the bottom Status bar can be displayed or hidden.

The Master Scale and the Color box can be opened from here.

The option "Tile vertically" set the Master Scale and Point

properties windows vertically on the right hand side. While the

option "Tile horizontally" set the Master Scale and Point properties

windows horizontally at the bottom of the screen.

The design window can display 1 to 3 panels.

The option "Compare Boards" allows you to view all open files side by side for comparison.

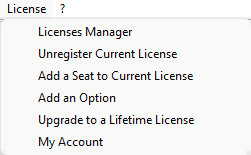

The menu License allows you registering your license, whether Shape3d has access to the Internet or not.

See menu Register your License for more details.

- The menu items Add a Seat to Current License, Add an Option, Renew Maintenance and My Account open your Internet browser to let you do these actions on the Shape3d.com website.

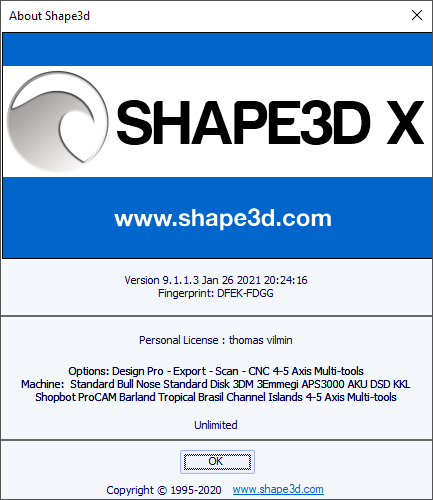

The menu "?", gives access to the online help (this manual plus the videos and FAQ, and the Warehouse where you can download many samples) and the version information.

- About Shape3d will give you the information about the version of Shape3d you're using, your license, and also the fingerprint of your computer:

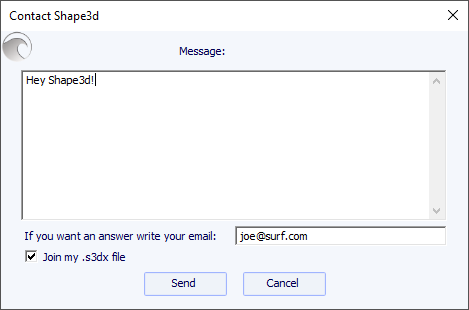

- Contact the Shape3d team allows you to send a message to the Shape3d team:

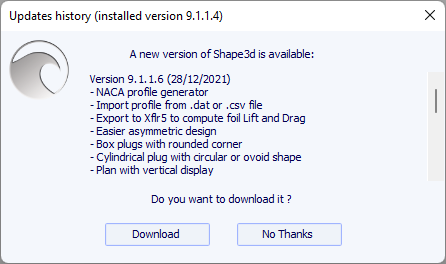

- In this menu you can also check the option Always check for update, so that you'll always know if there's a newer version if you're connected to the Internet. When an update is available, the following window will pop up at the opening of Shape3d, that lets you download the new version of Shape3d:

- You can also Check for update now.

- Finally, if you're connected to the Internet, you can check the Versions history that will redirect you to our website on the page UpdatesHistory.aspx that gives you the list of improvements that have been done on each version of Shape3d X.

The context menu appears when you right-click inside a panel.

It contains almost all the features of the menu bar, and allows using them quicker.

Note that by pressing the Shift key, the right-click will directly open the appropriate context submenu. For example Shift + right-click when the Slices panel is selected directly opens the Slices submenu, or the Control Point submenu if a control point is selected.

The Left Click

The left click allows selecting a control point or a guideline.

The Ctrl + Left Click

Ctrl + left click allow selecting several points, or guidelines.

The Shift + Left Click

Shift + left click allow selecting all the points, or guidelines, between two selections.

Shift + Ctrl + left click will select a control point in priority even if a guideline is displayed at the same position.

The Double Left Click

The double left click allows adding a control point or a guideline if the guidelines are shown on screen.

The Right Click

The right click makes the context menu appear.

The Shift + Right Click

Shift + Right click directly open the appropriate context submenu.

The Tab key

The Del key

Del will delete the selection.

The Ctrl + C keys

Ctrl + C copy the curve (outline, bottom, deck, thickness, or slice) in the clip-board. Then, you can past this curve on another board, or on another slice if the curve is a slice. Note that if you select one control point of the copied curve, and then one point of the other curve, it will copy-paste the whole curve. But you can also copy-paste just a section of curve by selecting the control points you want (press the Shift or Control keys while selecting the points). See The Tool Bar.

The Ctrl + V keys

Ctrl + V Paste the copied curve on the selected curve. See Ctrl + C and The Tool Bar.

The Ctrl + A keys

Ctrl + A selects all the points or all the guidelines.

The Ctrl + Z keys

Ctrl + Z call the Undo.

The Shift + Ctrl + Z keys

Shift + Ctrl + Z call the Redo.

The Ctrl + N keys

Ctrl + N open the New board window.

The Ctrl + O keys

Ctrl + O open the board files browser.

The Ctrl + S keys

Ctrl + S save the modifications.

The Ctrl + R keys

Ctrl + R save the modifications and load the actual shape as the reference shape.